Micro tunneling offers a highly precise, trenchless method for installing small-diameter pipelines with minimal surface disruption, ideal for urban environments with complex underground obstacles. HDD (Horizontal Directional Drilling) excels in installing larger pipelines over longer distances, providing greater flexibility in navigating around existing infrastructure and varying soil conditions. Both techniques reduce environmental impact and traffic disturbances compared to open-cut methods, but micro tunneling is often preferred for its accuracy and control in confined spaces.

Table of Comparison

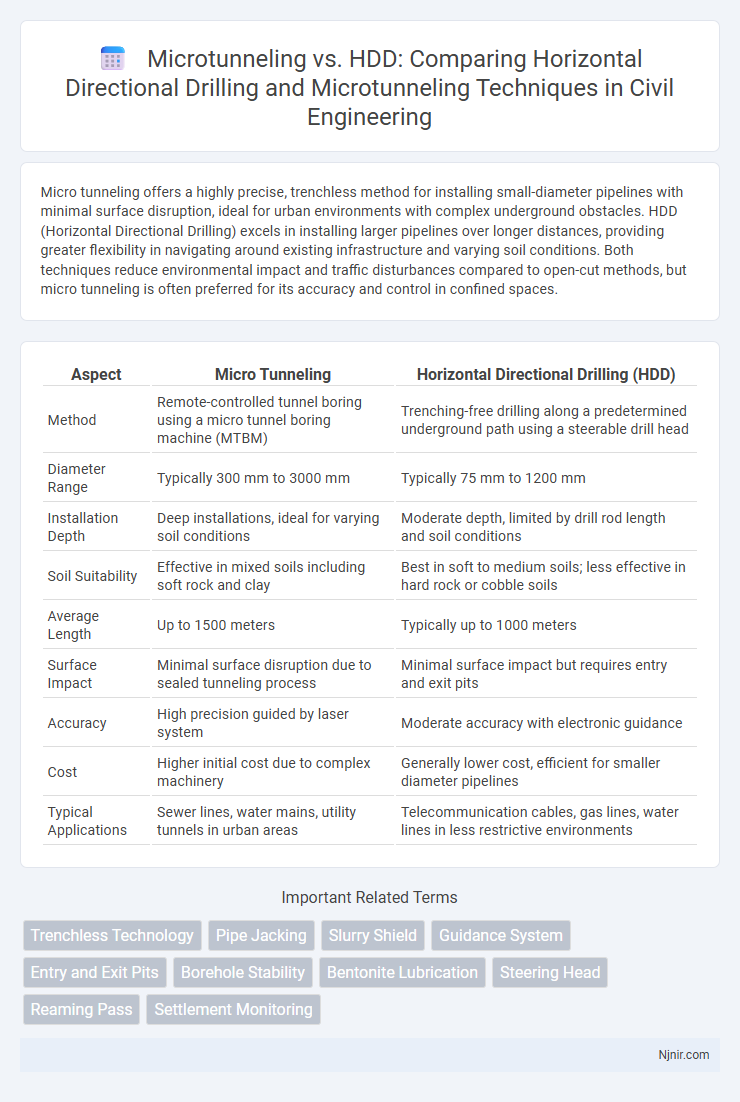

| Aspect | Micro Tunneling | Horizontal Directional Drilling (HDD) |

|---|---|---|

| Method | Remote-controlled tunnel boring using a micro tunnel boring machine (MTBM) | Trenching-free drilling along a predetermined underground path using a steerable drill head |

| Diameter Range | Typically 300 mm to 3000 mm | Typically 75 mm to 1200 mm |

| Installation Depth | Deep installations, ideal for varying soil conditions | Moderate depth, limited by drill rod length and soil conditions |

| Soil Suitability | Effective in mixed soils including soft rock and clay | Best in soft to medium soils; less effective in hard rock or cobble soils |

| Average Length | Up to 1500 meters | Typically up to 1000 meters |

| Surface Impact | Minimal surface disruption due to sealed tunneling process | Minimal surface impact but requires entry and exit pits |

| Accuracy | High precision guided by laser system | Moderate accuracy with electronic guidance |

| Cost | Higher initial cost due to complex machinery | Generally lower cost, efficient for smaller diameter pipelines |

| Typical Applications | Sewer lines, water mains, utility tunnels in urban areas | Telecommunication cables, gas lines, water lines in less restrictive environments |

Introduction to Micro Tunneling and HDD

Micro tunneling is a trenchless construction method using remote-controlled, guided machines to install pipelines with high precision under obstacles, minimizing surface disruption. Horizontal Directional Drilling (HDD) involves a pilot bore guided along a predetermined path followed by reaming and pipe installation, suitable for longer distances and larger diameters. Both techniques enable underground pipe installation without extensive excavation, enhancing efficiency in urban infrastructure projects.

Principles and Working Mechanisms

Micro tunneling uses a remote-controlled, guided boring machine that operates beneath the surface to create small-diameter tunnels with minimal ground disturbance, employing a slurry or auger system to remove excavated material. Horizontal Directional Drilling (HDD) involves drilling a pilot hole along a predetermined path, followed by enlarging the hole using reamers and pulling the pipeline through, relying on precise steering and tracking technologies. Both methods enable trenchless installation of underground utilities but differ in mechanisms, with micro tunneling emphasizing guided mechanical excavation and HDD focusing on directional drilling and hole enlargement.

Equipment and Technology Overview

Micro tunneling involves remote-controlled tunneling machines with laser guidance systems and slurry or auger removal methods, enabling precise small-diameter pipe installations in urban environments. In contrast, Horizontal Directional Drilling (HDD) employs steerable drill heads, mud motors, and tracking systems to create larger-diameter bores for utility installations under obstacles without surface disruption. Both technologies utilize advanced computerized monitoring and GPS to ensure accuracy, but micro tunneling typically offers higher precision and is suited for smaller, more complex underground installations.

Key Applications in Civil Engineering

Micro tunneling excels in constructing small to medium-diameter underground pipelines with precise alignment and minimal surface disruption, commonly used for sewer, water, and utility installations beneath urban areas. HDD (Horizontal Directional Drilling) is ideal for longer, larger-diameter crossings where avoiding surface obstacles such as roads, rivers, or environmentally sensitive zones is critical, frequently applied for gas, oil, and telecommunications pipeline installations. Both techniques enhance trenchless construction efficiency, with micro tunneling favored for controlled environments and HDD preferred for flexible routing over extended distances.

Site Suitability and Soil Conditions

Micro tunneling excels in sites with constrained surface space, providing precise control in urban areas and beneath existing infrastructure, especially in stable to moderately variable soil conditions such as clay, silt, and sand. HDD (Horizontal Directional Drilling) is suitable for longer, less constrained alignments with flexible surface access, ideal for drilling through softer soils like sand, gravel, and some fractured rock but may struggle in highly unstable or rocky soil conditions. Site suitability for micro tunneling is enhanced by its closed-face operation and pipe jacking capability, while HDD requires careful soil assessment to avoid collapses and drilling fluid loss in permeable or highly fissured soils.

Installation Accuracy and Control

Micro tunneling offers superior installation accuracy and control due to its use of remotely operated, guided boring machines that maintain precise alignment and gradient throughout the pipeline installation. Horizontal Directional Drilling (HDD) relies more heavily on pilot hole steering with less continuous monitoring, which can result in lower precision, especially in challenging soil conditions. The closed system of micro tunneling minimizes deviation risks and allows real-time adjustments, making it preferable for projects requiring high accuracy in pipeline placement.

Cost Comparison and Budget Factors

Micro tunneling typically incurs higher upfront costs due to advanced equipment and precise control requirements, with expenses ranging from $1,000 to $2,500 per linear foot depending on soil conditions and tunnel diameter. HDD generally offers a more cost-effective solution, averaging $50 to $250 per linear foot, though budget factors such as pipe material, project length, and potential for borehole collapse can significantly influence total costs. Project complexity, site accessibility, and environmental constraints further affect budget allocation, making accurate cost estimation essential during the planning phase.

Environmental Impact and Safety

Micro tunneling minimizes surface disruption by operating entirely below ground, significantly reducing soil erosion and habitat disturbance compared to Horizontal Directional Drilling (HDD), which may cause inadvertent fracturing and inadvertent release of drilling fluids into groundwater. The controlled, remote-guided process of micro tunneling enhances worker safety by limiting human entry into confined spaces, whereas HDD involves higher exposure to airborne contaminants and potential drilling fluid spills. Environmental risks linked with HDD include inadvertent returns and potential contamination, making micro tunneling a safer option in sensitive ecological zones.

Project Timeline and Efficiency

Micro tunneling offers precise control and faster completion for small-diameter pipelines in urban environments, often reducing project timelines by minimizing surface disruption and utility conflicts. HDD (Horizontal Directional Drilling) excels in longer distances and larger diameters but typically requires more time for site setup, pilot drilling, and reaming, affecting overall project efficiency in complex ground conditions. Choosing between micro tunneling and HDD depends on balancing project scope, ground conditions, and desired installation speed to optimize timeline and operational efficiency.

Selection Criteria and Best Practices

Micro tunneling and Horizontal Directional Drilling (HDD) selection depends heavily on project scale, soil conditions, and utility congestion. Micro tunneling is preferred for smaller diameter pipelines in urban environments with minimal ground disturbance, where precise alignment and minimal surface disruption are critical. HDD suits longer, larger diameter crossings with varied soil profiles, demanding careful pre-drill surveys and continuous monitoring to manage bore path accuracy and avoid environmental impact.

Trenchless Technology

Micro tunneling offers precise pipe installation with minimal surface disruption and is ideal for smaller diameters and challenging soil conditions, while HDD excels in longer, larger-diameter boreholes with greater flexibility in alignment, both advancing trenchless technology for efficient underground utility installation.

Pipe Jacking

Micro tunneling offers precise, remotely controlled pipe jacking suitable for small-diameter, high-accuracy installations, whereas HDD excels in longer, flexible bore paths but lacks the rigid pipe jacking control of micro tunneling.

Slurry Shield

Micro tunneling's slurry shield provides superior soil stabilization and reduced ground settlement compared to HDD, making it ideal for complex underground installations beneath sensitive structures.

Guidance System

Micro tunneling employs advanced laser-guided systems for precise subterranean navigation, whereas HDD relies on Gyroscopic and Inertial Navigation Systems (INS) to maintain directional control over long distances.

Entry and Exit Pits

Micro tunneling requires smaller, more precise entry and exit pits compared to the larger, more accessible pits needed for Horizontal Directional Drilling (HDD) to accommodate drill rigs and pipe handling.

Borehole Stability

Micro tunneling ensures superior borehole stability through precise remote-controlled excavation and continuous pipe jacking, whereas HDD may experience greater instability due to variable soil conditions and reliance on fluid pressure for borehole support.

Bentonite Lubrication

Micro tunneling uses bentonite lubrication to reduce friction and stabilize the borehole, while HDD relies on bentonite slurry for efficient cuttings transport and borehole support.

Steering Head

The steering head in micro tunneling offers precise guidance and real-time adjustments for smaller diameter pipelines, while HDD's steering systems provide greater flexibility and range for larger, deeper installations.

Reaming Pass

Micro tunneling offers precise borehole control with minimal surface disruption, whereas HDD typically requires multiple reaming passes to enlarge the borehole, impacting project duration and soil stability.

Settlement Monitoring

Micro tunneling offers enhanced precision and reduces surface settlement compared to HDD (Horizontal Directional Drilling), making it more reliable for projects requiring stringent settlement monitoring.

Micro tunneling vs HDD (Horizontal Directional Drilling) Infographic

njnir.com

njnir.com