Curing compound forms a protective film on concrete surfaces, reducing moisture loss and accelerating strength development, making it ideal for large or complex structures where water curing is impractical. Water curing ensures continuous hydration by maintaining wet conditions, enhancing concrete durability and minimizing shrinkage cracks, especially critical in hot or arid environments. Choosing between curing compound and water curing depends on project scale, environmental conditions, and resource availability to optimize concrete performance.

Table of Comparison

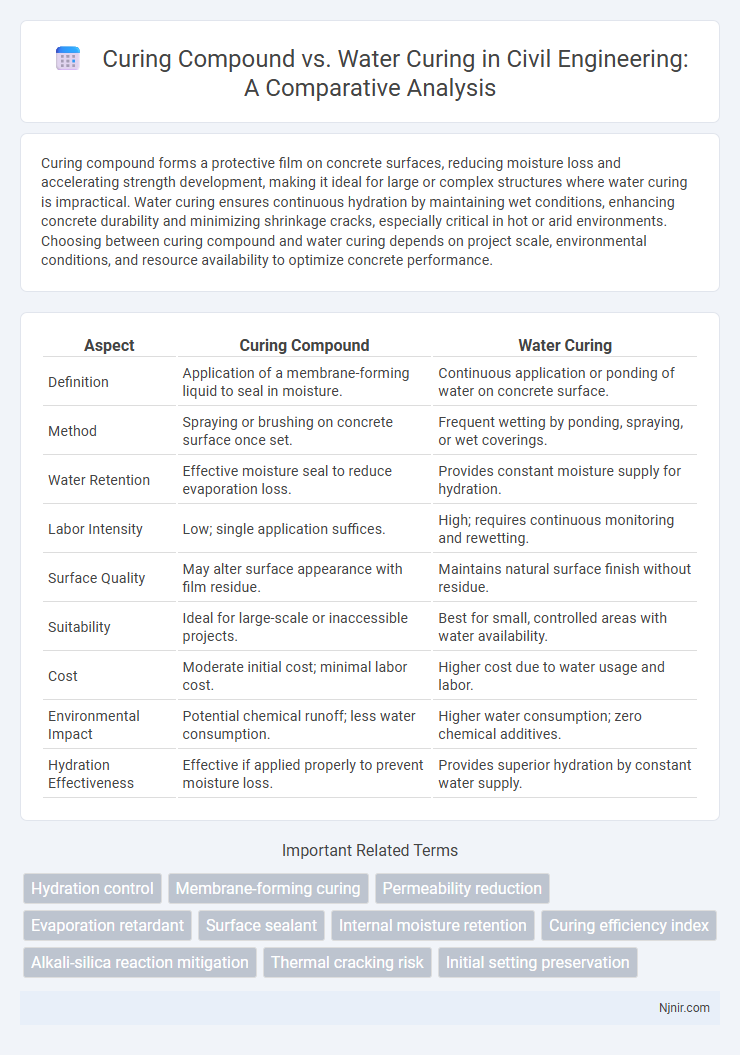

| Aspect | Curing Compound | Water Curing |

|---|---|---|

| Definition | Application of a membrane-forming liquid to seal in moisture. | Continuous application or ponding of water on concrete surface. |

| Method | Spraying or brushing on concrete surface once set. | Frequent wetting by ponding, spraying, or wet coverings. |

| Water Retention | Effective moisture seal to reduce evaporation loss. | Provides constant moisture supply for hydration. |

| Labor Intensity | Low; single application suffices. | High; requires continuous monitoring and rewetting. |

| Surface Quality | May alter surface appearance with film residue. | Maintains natural surface finish without residue. |

| Suitability | Ideal for large-scale or inaccessible projects. | Best for small, controlled areas with water availability. |

| Cost | Moderate initial cost; minimal labor cost. | Higher cost due to water usage and labor. |

| Environmental Impact | Potential chemical runoff; less water consumption. | Higher water consumption; zero chemical additives. |

| Hydration Effectiveness | Effective if applied properly to prevent moisture loss. | Provides superior hydration by constant water supply. |

Introduction to Concrete Curing Methods

Concrete curing methods significantly impact the strength and durability of concrete structures by controlling moisture retention during the hydration process. Curing compounds form a protective film on the concrete surface, reducing evaporation and maintaining moisture without additional water application, while water curing involves continuously wetting the concrete to supply moisture for hydration. Selecting the appropriate curing method depends on environmental conditions, concrete mix, and project requirements to optimize performance and longevity.

Importance of Proper Concrete Curing

Proper concrete curing ensures optimal hydration, strength development, and durability by maintaining adequate moisture levels. Curing compounds provide a protective film to reduce evaporation, while water curing continuously supplies moisture for sustained hydration. Selecting the appropriate method based on environmental conditions and project requirements is critical to prevent cracking and enhance concrete performance.

Overview of Curing Compounds

Curing compounds form a protective membrane on concrete surfaces, minimizing moisture loss and accelerating hydration to enhance strength development and durability. These compounds include liquid membranes such as wax, resin, or acrylic-based formulations, providing an effective alternative to traditional water curing methods in environments with limited water availability. Their ease of application and ability to reduce surface cracking make curing compounds a preferred choice in large-scale infrastructure projects and precast concrete manufacturing.

Water Curing: Process and Techniques

Water curing involves maintaining adequate moisture on concrete surfaces to ensure proper hydration and strength development. Techniques include continuous spraying, ponding, or covering with wet burlap to prevent evaporation and enhance curing efficiency. This process significantly reduces shrinkage cracks and improves durability by promoting uniform cement hydration.

Key Differences: Curing Compound vs Water Curing

Curing compound creates a protective film to retain moisture in concrete, whereas water curing continuously supplies moisture through methods like spraying, ponding, or wet coverings. Unlike water curing, curing compounds require less labor and prevent water evaporation but may affect surface texture and bonding with subsequent coatings. Water curing ensures uniform hydration and strength development but demands constant moisture maintenance and increased labor.

Advantages of Curing Compounds

Curing compounds provide a consistent moisture barrier that significantly reduces water evaporation and ensures uniform hydration, leading to improved concrete strength and durability. These compounds are easy to apply, require less labor and water resources than traditional water curing, and are effective even in windy or hot conditions where water curing may fail. By minimizing surface cracking and enhancing resistance to abrasion and freeze-thaw cycles, curing compounds contribute to longer-lasting concrete structures.

Benefits of Water Curing

Water curing enhances concrete strength and durability by maintaining optimal moisture levels essential for proper hydration, reducing surface cracking and shrinkage. It improves long-term performance, resistance to abrasion, and freeze-thaw cycles compared to curing compounds that may create a moisture barrier but cannot replenish water. Consistent water curing promotes uniform curing, resulting in denser, more resilient concrete structures.

Limitations and Challenges of Each Method

Curing compound application can suffer from uneven coverage and may create a surface barrier that limits moisture exchange, potentially leading to weaker surface strength. Water curing demands continuous water availability and proper coverage, which can be challenging in large or complex structures and may result in water wastage or difficulty maintaining optimal moisture levels. Both methods face challenges in ensuring uniform curing conditions, impacting the overall durability and strength of concrete.

Applications: When to Use Each Curing Technique

Curing compound is ideal for large-scale concrete projects where uniform moisture retention is critical, such as highways, bridges, and slabs, ensuring rapid application and minimal labor. Water curing is preferred for smaller or detailed structures like columns, walls, and precast elements, demanding continuous moisture and better temperature control to enhance strength and durability. Selection depends on project size, exposure conditions, and practical constraints, with curing compound favored for ease and speed, while water curing suits precision and prolonged moisture requirements.

Best Practices for Effective Concrete Curing

Applying curing compounds forms a protective membrane that retains moisture within the concrete, ensuring uniform hydration and preventing surface evaporation. Water curing involves continuous wetting methods such as ponding or mist spraying to maintain adequate moisture levels critical for strength development and durability. To achieve optimal concrete performance, best practices integrate timely application of curing compounds immediately after finishing or consistent water curing for at least seven days under suitable environmental conditions.

Hydration control

Curing compounds form a protective membrane to reduce surface moisture loss and control hydration, whereas water curing ensures continuous moisture supply for optimal cement hydration and strength development.

Membrane-forming curing

Membrane-forming curing compounds create a protective barrier that reduces water evaporation and enhances concrete hydration compared to traditional water curing methods.

Permeability reduction

Curing compounds significantly reduce concrete permeability by forming a protective film that limits moisture loss, whereas water curing achieves permeability reduction through continuous hydration and pore refinement.

Evaporation retardant

Curing compounds act as effective evaporation retardants by forming a protective film on concrete surfaces, whereas water curing relies on continuous moisture application without directly preventing surface water evaporation.

Surface sealant

Curing compounds provide a durable surface sealant that reduces moisture loss more effectively than traditional water curing methods.

Internal moisture retention

Curing compounds enhance internal moisture retention by forming a protective film over concrete surfaces, whereas water curing maintains moisture through continuous wetting, both methods being essential for preventing premature drying and ensuring optimal hydration.

Curing efficiency index

Curing compounds typically achieve a higher Curing Efficiency Index than water curing by providing more consistent moisture retention and reducing evaporation rates.

Alkali-silica reaction mitigation

Applying curing compounds significantly reduces Alkali-silica reaction by limiting moisture ingress and controlling alkali mobilization, whereas water curing provides continuous moisture that may accelerate ASR expansion in susceptible concrete.

Thermal cracking risk

Using curing compounds reduces thermal cracking risk by maintaining consistent moisture levels, whereas water curing can increase risk due to uneven evaporation and temperature gradients.

Initial setting preservation

Curing compounds effectively preserve the initial setting of concrete by forming a moisture-retentive film, while water curing maintains initial setting through continuous hydration and temperature regulation.

Curing compound vs Water curing Infographic

njnir.com

njnir.com