Green concrete reduces environmental impact by incorporating industrial waste materials and recycled aggregates, significantly lowering carbon emissions compared to traditional concrete. It enhances sustainability through improved durability and energy efficiency in construction projects. Traditional concrete, while widely used, relies heavily on cement production, which contributes to high greenhouse gas emissions and resource depletion.

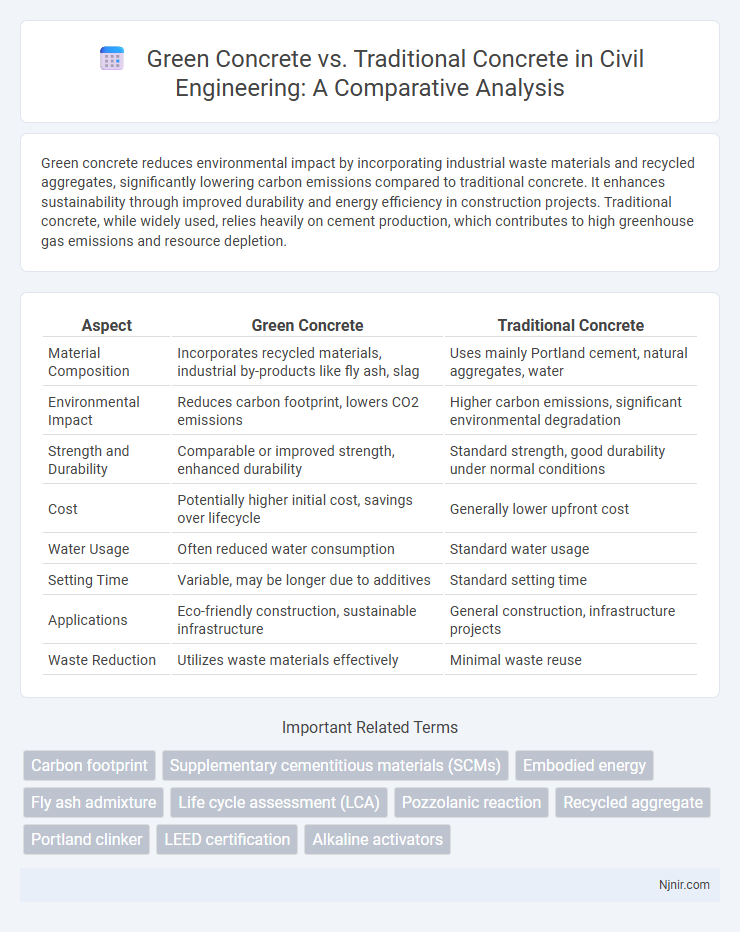

Table of Comparison

| Aspect | Green Concrete | Traditional Concrete |

|---|---|---|

| Material Composition | Incorporates recycled materials, industrial by-products like fly ash, slag | Uses mainly Portland cement, natural aggregates, water |

| Environmental Impact | Reduces carbon footprint, lowers CO2 emissions | Higher carbon emissions, significant environmental degradation |

| Strength and Durability | Comparable or improved strength, enhanced durability | Standard strength, good durability under normal conditions |

| Cost | Potentially higher initial cost, savings over lifecycle | Generally lower upfront cost |

| Water Usage | Often reduced water consumption | Standard water usage |

| Setting Time | Variable, may be longer due to additives | Standard setting time |

| Applications | Eco-friendly construction, sustainable infrastructure | General construction, infrastructure projects |

| Waste Reduction | Utilizes waste materials effectively | Minimal waste reuse |

Introduction to Green Concrete and Traditional Concrete

Green concrete incorporates eco-friendly materials such as recycled aggregates, fly ash, and slag to reduce carbon emissions and energy consumption compared to traditional concrete, which primarily utilizes cement, water, and natural aggregates like sand and gravel. Traditional concrete production contributes significantly to CO2 emissions due to the high energy required for cement manufacturing, whereas green concrete aims to minimize environmental impact by enhancing resource efficiency and durability. Innovations in green concrete not only reduce the carbon footprint but also improve sustainability in construction through the use of industrial by-products and waste materials.

Composition and Material Sourcing

Green concrete utilizes industrial by-products such as fly ash, slag, and silica fume as partial replacements for Portland cement, significantly reducing carbon emissions and natural resource consumption. Traditional concrete relies heavily on Portland cement and virgin aggregates sourced from quarries, contributing to higher environmental impact and resource depletion. The sustainable sourcing of recycled materials in green concrete enhances its eco-friendly profile while maintaining structural performance standards.

Environmental Impact and Sustainability

Green concrete reduces carbon emissions by incorporating industrial by-products like fly ash and slag, significantly lowering the cement content compared to traditional concrete, which predominantly relies on Portland cement with a high carbon footprint. Its use of recycled materials minimizes landfill waste and conserves natural resources, enhancing sustainability in construction projects. Traditional concrete's production is energy-intensive and contributes to substantial CO2 emissions, whereas green concrete supports circular economy principles and promotes eco-friendly building practices.

Mechanical and Physical Properties

Green concrete, incorporating industrial by-products like fly ash and slag, exhibits enhanced mechanical strength and improved durability compared to traditional concrete, with compressive strengths often matching or exceeding standard mixes. Its reduced permeability and better resistance to chemical attacks result in superior physical properties, including lower shrinkage and enhanced thermal insulation. Traditional concrete, while reliable and widely used, typically shows higher susceptibility to cracking and environmental degradation over time due to its reliance on Portland cement.

Durability and Longevity

Green concrete, incorporating recycled materials and industrial by-products like fly ash and slag, exhibits enhanced durability by reducing permeability and improving resistance to chemical attacks compared to traditional concrete. Its improved microstructure minimizes cracking and extends structural lifespan, often surpassing traditional concrete's longevity in harsh environmental conditions. Studies show green concrete can achieve service lives exceeding 100 years, contributing to sustainable infrastructure with lower maintenance costs.

Cost Comparison and Economic Feasibility

Green concrete generally incurs higher initial costs due to the use of eco-friendly materials and advanced manufacturing processes compared to traditional concrete, which relies on standard cement and aggregates. However, long-term economic feasibility improves with green concrete through reduced energy consumption, lower maintenance expenses, and potential government incentives for sustainable construction. Cost-benefit analyses indicate that despite upfront investments, green concrete offers significant savings over the lifecycle of infrastructure projects, enhancing overall economic viability.

Workability and Construction Practices

Green concrete exhibits enhanced workability due to its use of supplementary cementitious materials like fly ash and slag, which improve consistency and reduce water demand compared to traditional concrete. Construction practices with green concrete often require adjustments in curing times and mixing protocols to optimize strength development and durability. Contractors benefit from tailored techniques that accommodate green concrete's unique setting characteristics, promoting sustainable building without compromising performance.

Performance in Various Climates

Green concrete demonstrates superior durability and thermal insulation compared to traditional concrete, making it more effective in extreme temperatures and varying humidity levels. Its use of recycled materials and additives enhances resistance to cracking and weathering, ensuring long-term structural integrity in both hot and cold climates. Traditional concrete tends to suffer from thermal expansion and freeze-thaw cycles, leading to reduced lifespan and increased maintenance costs.

Regulatory Standards and Compliance

Green concrete must meet evolving environmental regulations such as ASTM C1157 and Eurocode standards focusing on reduced carbon emissions and the use of sustainable materials. Traditional concrete complies primarily with ASTM C150 and ACI 318, emphasizing strength, durability, and load-bearing capacity without strict environmental mandates. Regulatory frameworks increasingly prioritize green concrete for LEED certification and carbon footprint reduction targets in construction projects.

Future Trends in Concrete Technology

Green concrete, incorporating recycled materials and low-carbon binders, is revolutionizing construction by reducing environmental impact and enhancing sustainability. Future trends emphasize advancements in nanomaterials, self-healing properties, and carbon capture integration to improve durability and carbon footprint. Smart concrete technologies and 3D printing compatibility are expected to drive efficiency and innovation in infrastructure development.

Carbon footprint

Green concrete reduces the carbon footprint by utilizing recycled materials and industrial byproducts, resulting in up to 40% lower CO2 emissions compared to traditional concrete.

Supplementary cementitious materials (SCMs)

Supplementary cementitious materials (SCMs) in green concrete reduce environmental impact by replacing a portion of traditional cement, enhancing durability and lowering carbon emissions compared to traditional concrete.

Embodied energy

Green concrete significantly reduces embodied energy by incorporating recycled materials and industrial byproducts compared to traditional concrete, which relies heavily on energy-intensive cement production.

Fly ash admixture

Green concrete using fly ash admixture reduces cement consumption by up to 30%, lowers carbon emissions by approximately 40%, and enhances durability compared to traditional concrete.

Life cycle assessment (LCA)

Green concrete demonstrates a significantly lower environmental impact in life cycle assessment (LCA) compared to traditional concrete, primarily due to reduced carbon emissions and energy consumption during production and disposal phases.

Pozzolanic reaction

Green concrete leverages the pozzolanic reaction by incorporating supplementary cementitious materials like fly ash and slag, enhancing durability and reducing carbon emissions compared to traditional concrete that primarily relies on Portland cement hydration.

Recycled aggregate

Green concrete utilizes recycled aggregate from construction waste to reduce environmental impact, whereas traditional concrete relies primarily on virgin materials with higher carbon emissions.

Portland clinker

Green concrete reduces Portland clinker usage by incorporating eco-friendly substitutes like fly ash and slag, significantly lowering carbon emissions compared to traditional concrete.

LEED certification

Green concrete enhances LEED certification potential by reducing carbon emissions and incorporating recycled materials compared to traditional concrete.

Alkaline activators

Green concrete utilizing alkaline activators like sodium hydroxide and sodium silicate demonstrates enhanced sustainability and improved mechanical properties compared to traditional concrete.

Green concrete vs Traditional concrete Infographic

njnir.com

njnir.com