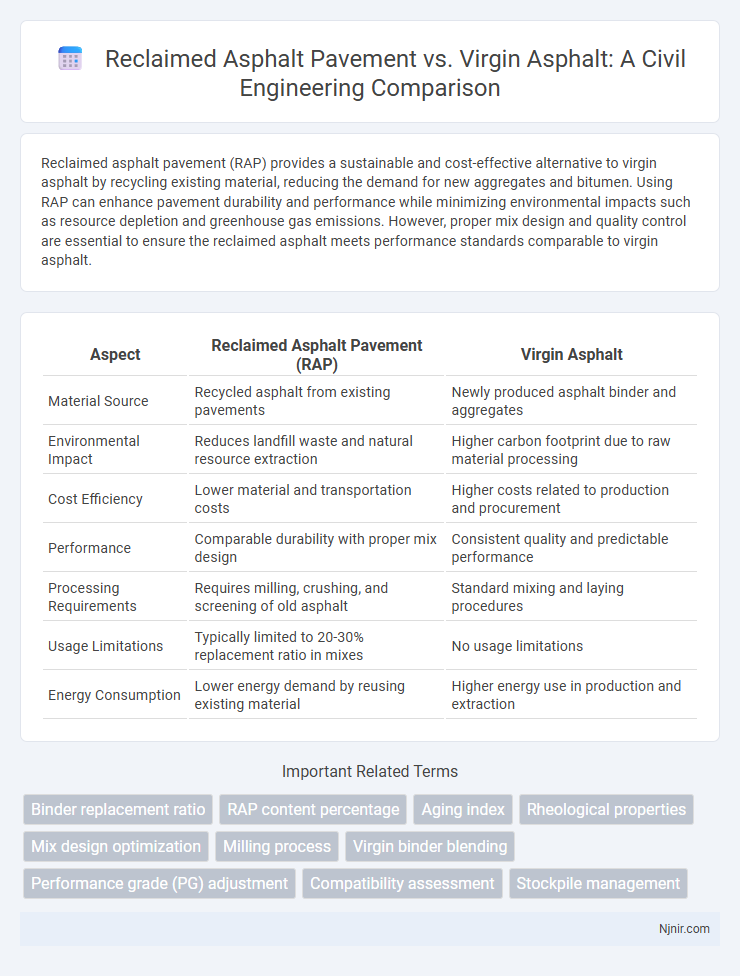

Reclaimed asphalt pavement (RAP) provides a sustainable and cost-effective alternative to virgin asphalt by recycling existing material, reducing the demand for new aggregates and bitumen. Using RAP can enhance pavement durability and performance while minimizing environmental impacts such as resource depletion and greenhouse gas emissions. However, proper mix design and quality control are essential to ensure the reclaimed asphalt meets performance standards comparable to virgin asphalt.

Table of Comparison

| Aspect | Reclaimed Asphalt Pavement (RAP) | Virgin Asphalt |

|---|---|---|

| Material Source | Recycled asphalt from existing pavements | Newly produced asphalt binder and aggregates |

| Environmental Impact | Reduces landfill waste and natural resource extraction | Higher carbon footprint due to raw material processing |

| Cost Efficiency | Lower material and transportation costs | Higher costs related to production and procurement |

| Performance | Comparable durability with proper mix design | Consistent quality and predictable performance |

| Processing Requirements | Requires milling, crushing, and screening of old asphalt | Standard mixing and laying procedures |

| Usage Limitations | Typically limited to 20-30% replacement ratio in mixes | No usage limitations |

| Energy Consumption | Lower energy demand by reusing existing material | Higher energy use in production and extraction |

Introduction to Reclaimed Asphalt Pavement and Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) consists of recycled materials from old asphalt surfaces, offering a sustainable alternative to virgin asphalt by reducing the need for new raw materials. Virgin asphalt is produced from fresh aggregates and bitumen, ensuring consistent quality and performance for new pavement constructions. Utilizing RAP promotes environmental benefits such as lower carbon emissions and resource conservation compared to traditional virgin asphalt production.

Material Composition and Properties

Reclaimed asphalt pavement (RAP) consists primarily of aged asphalt binder and aggregates recovered from milled or removed pavement layers, offering a lower cost and environmentally friendly alternative to virgin asphalt, which is composed of fresh aggregates and unaged asphalt binder. The aged binder in RAP exhibits increased stiffness and reduced ductility compared to virgin binder, influencing the overall mechanical properties and requiring careful mix design adjustments to balance performance and durability. Virgin asphalt mixtures provide more consistent material properties and predictable performance, whereas RAP materials require thorough evaluation to mitigate potential issues such as reduced fatigue resistance and increased susceptibility to cracking.

Environmental Impact Comparison

Reclaimed asphalt pavement (RAP) significantly reduces environmental impact by lowering the demand for new raw materials, which decreases energy consumption and greenhouse gas emissions associated with asphalt production. Using RAP diverts asphalt from landfills, promoting sustainable material reuse and minimizing construction waste. In contrast, virgin asphalt requires extensive extraction of petroleum and aggregates, leading to higher carbon footprints and resource depletion.

Cost Analysis: Reclaimed vs Virgin Asphalt

Reclaimed asphalt pavement (RAP) offers significant cost savings compared to virgin asphalt due to reduced material and transportation expenses, often lowering project costs by 20-50%. Virgin asphalt requires more energy-intensive production and higher raw material costs, driving up overall prices. Incorporating RAP not only minimizes expenditure but also supports sustainable construction practices by recycling existing materials.

Performance and Durability in Pavement Applications

Reclaimed asphalt pavement (RAP) demonstrates comparable performance and durability to virgin asphalt in pavement applications when properly processed and mixed, offering enhanced resistance to cracking and rutting due to improved aggregate interlock. The incorporation of RAP reduces aging effects while maintaining adequate binder quality, ensuring long-term pavement resilience under heavy traffic loads. Studies indicate that optimizing RAP content can achieve equal or superior mechanical properties, extending the service life of asphalt pavements while enabling sustainable construction practices.

Construction Techniques and Best Practices

Reclaimed asphalt pavement (RAP) offers a sustainable construction technique by recycling existing materials, reducing the need for virgin asphalt and lowering project costs. Best practices include proper milling and grading of RAP materials, ensuring adequate blending ratios with virgin asphalt binder, and controlling temperature during mixing to maintain pavement performance. Using RAP requires specialized equipment and quality control measures to achieve durability comparable to virgin asphalt while minimizing environmental impact.

Regulatory Standards and Guidelines

Regulatory standards for reclaimed asphalt pavement (RAP) emphasize environmental sustainability and material performance, often requiring specific protocols for processing and quality control to ensure compliance with local and federal agencies such as the EPA and FHWA. Virgin asphalt is typically governed by more stringent purity and performance criteria outlined in standards from ASTM and AASHTO, focusing on binder consistency and aggregate properties to meet predictable engineering specifications. Both materials must adhere to pavement design guidelines promoting durability and safety, while RAP usage is increasingly supported by regulations incentivizing recycling and reducing carbon footprints.

Case Studies: Real-World Applications

Case studies reveal that reclaimed asphalt pavement (RAP) can reduce project costs by up to 30% while maintaining comparable durability to virgin asphalt in highway construction. Projects in Minnesota and Texas demonstrate RAP mixtures achieving performance ratings above 85% after five years, highlighting sustainability benefits and reduced environmental impact. Real-world applications in urban roads show that incorporating 20-40% RAP content preserves structural integrity and extends pavement lifecycle, confirming its feasibility for large-scale infrastructure.

Challenges and Limitations of Each Material

Reclaimed asphalt pavement (RAP) poses challenges such as variability in aggregate quality, potential contamination, and aging effects that impact binder performance and mix consistency. Virgin asphalt offers uniformity and predictable properties, but its extraction and production are energy-intensive and contribute significantly to environmental pollution. Both materials face limitations in meeting specific performance requirements, requiring careful design and quality control to optimize durability and sustainability in pavement construction.

Future Trends in Asphalt Pavement Technology

Future trends in asphalt pavement technology emphasize increased use of reclaimed asphalt pavement (RAP) due to its environmental benefits and cost savings, promoting sustainability in road construction. Advances in binder rejuvenators and warm-mix asphalt techniques enhance the performance and durability of RAP mixtures, narrowing the performance gap with virgin asphalt. Innovations in recycling technologies and smart materials further support the integration of RAP, aligning with global goals for reducing carbon emissions and resource consumption in pavement infrastructure.

Binder replacement ratio

Reclaimed asphalt pavement (RAP) can replace up to 30-50% of virgin asphalt binder in hot mix asphalt, significantly reducing the need for new binder while maintaining performance.

RAP content percentage

Reclaimed asphalt pavement (RAP) content typically ranges from 15% to 40% in mixtures, whereas virgin asphalt uses 100% new aggregate and binder.

Aging index

Reclaimed asphalt pavement (RAP) exhibits a lower aging index compared to virgin asphalt, indicating enhanced durability and extended service life in pavement applications.

Rheological properties

Reclaimed asphalt pavement exhibits altered rheological properties compared to virgin asphalt, including increased stiffness and reduced elasticity due to aging and oxidation effects.

Mix design optimization

Optimizing mix design using reclaimed asphalt pavement (RAP) improves cost efficiency and sustainability while maintaining performance comparable to virgin asphalt by carefully balancing binder content and aggregate gradation.

Milling process

The milling process in reclaimed asphalt pavement (RAP) efficiently removes and recycles existing asphalt layers to reduce material costs and environmental impact compared to the extraction and processing required for virgin asphalt.

Virgin binder blending

Virgin binder blending in reclaimed asphalt pavement enhances pavement durability by optimizing binder performance compared to using virgin asphalt alone.

Performance grade (PG) adjustment

Reclaimed asphalt pavement (RAP) requires careful Performance Grade (PG) adjustments to the binder to maintain durability and optimize temperature susceptibility compared to virgin asphalt.

Compatibility assessment

Reclaimed asphalt pavement (RAP) demonstrates high compatibility with virgin asphalt binders when properly characterized and blended, enhancing sustainability without compromising pavement performance.

Stockpile management

Effective stockpile management of reclaimed asphalt pavement (RAP) reduces material degradation and ensures consistent quality compared to virgin asphalt, enhancing project sustainability and cost-efficiency.

Reclaimed asphalt pavement vs virgin asphalt Infographic

njnir.com

njnir.com