Digital twin technology in geotechnics offers real-time, dynamic simulation and monitoring of subsurface conditions, enhancing predictive analysis and decision-making beyond the static nature of traditional BIM models. While BIM provides detailed 3D representations and integrates geological data during design and construction phases, digital twins continuously update with sensor data, enabling proactive management of ground behavior and infrastructure performance. The convergence of digital twins and BIM can optimize geological engineering processes by merging comprehensive modeling with real-time data analytics.

Table of Comparison

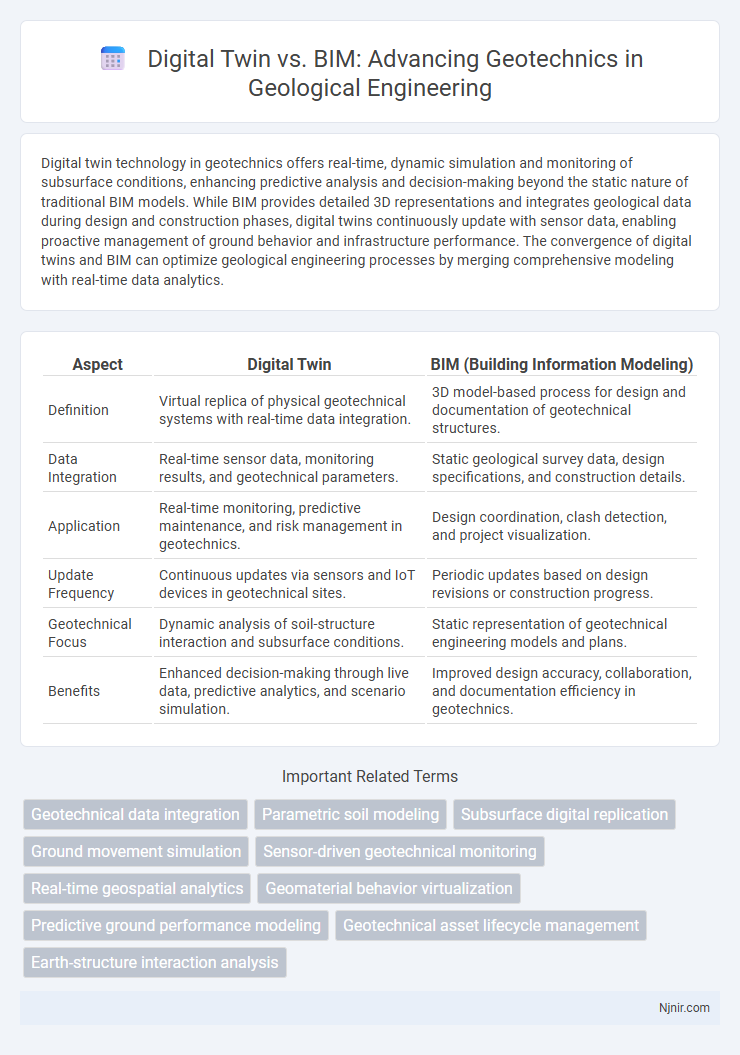

| Aspect | Digital Twin | BIM (Building Information Modeling) |

|---|---|---|

| Definition | Virtual replica of physical geotechnical systems with real-time data integration. | 3D model-based process for design and documentation of geotechnical structures. |

| Data Integration | Real-time sensor data, monitoring results, and geotechnical parameters. | Static geological survey data, design specifications, and construction details. |

| Application | Real-time monitoring, predictive maintenance, and risk management in geotechnics. | Design coordination, clash detection, and project visualization. |

| Update Frequency | Continuous updates via sensors and IoT devices in geotechnical sites. | Periodic updates based on design revisions or construction progress. |

| Geotechnical Focus | Dynamic analysis of soil-structure interaction and subsurface conditions. | Static representation of geotechnical engineering models and plans. |

| Benefits | Enhanced decision-making through live data, predictive analytics, and scenario simulation. | Improved design accuracy, collaboration, and documentation efficiency in geotechnics. |

Introduction to Digital Twin and BIM in Geotechnics

Digital Twin in geotechnics provides a dynamic, real-time virtual replica of soil and subsurface conditions, enabling continuous monitoring and predictive analysis for infrastructure projects. Building Information Modeling (BIM) integrates geotechnical data into detailed 3D models to enhance design accuracy, collaboration, and construction planning. Combining Digital Twin and BIM accelerates decision-making by merging real-time data with comprehensive geotechnical models for optimized project outcomes.

Core Concepts: Defining Digital Twin and BIM

Digital Twin in geotechnics represents a dynamic, real-time digital replica of subsurface conditions, integrating sensor data and simulations to monitor soil behavior and structural performance continuously. Building Information Modeling (BIM) is a static, data-rich 3D digital representation focusing on design, analysis, and documentation of geotechnical elements before and during construction. While BIM provides detailed geometric and attribute data for planning and visualization, Digital Twin enables ongoing operational insight and adaptive decision-making through continuous data updates.

Evolution of Digital Technologies in Geological Engineering

Digital twin technology in geotechnics represents the advanced evolution of Building Information Modeling (BIM) by enabling real-time simulation and monitoring of subsurface conditions, integrating sensor data with geological models for dynamic decision-making. BIM primarily supports static visualization and planning of geotechnical structures, whereas digital twins facilitate continuous updates and predictive analytics through IoT and machine learning applications, enhancing risk assessment and project optimization. The progression from BIM to digital twins underscores the transformation in geological engineering, driven by digital technologies that improve accuracy, efficiency, and resilience in managing complex underground works.

Key Functional Differences: Digital Twin vs BIM

Digital Twin in geotechnics enables real-time monitoring and dynamic simulation of soil-structure interactions, offering predictive analytics based on live sensor data. BIM primarily focuses on the static 3D modeling and documentation of geotechnical designs and subsurface conditions, supporting project planning and coordination. Unlike BIM, Digital Twin integrates continuous data updates for operational optimization and risk management throughout the infrastructure lifecycle.

Data Integration and Real-Time Monitoring in Geotechnical Projects

Digital twin technology in geotechnics enables continuous real-time monitoring by integrating sensor data and geotechnical models, providing dynamic updates on soil behavior and structural performance. Building Information Modeling (BIM) primarily offers detailed static 3D representations and project data consolidation but lacks real-time data assimilation crucial for monitoring subsurface conditions. The synergy of digital twin's live data integration with BIM's comprehensive structural information enhances predictive analytics and decision-making throughout geotechnical project lifecycles.

Applications of BIM in Geotechnical Design and Construction

BIM in geotechnical design enables detailed visualization and analysis of subsurface conditions, improving foundation planning and soil-structure interaction modeling. Applications of BIM include integration of borehole data, geotechnical instrumentation monitoring, and automated clash detection for underground utilities. Enhanced collaboration between engineers and contractors through BIM reduces risks and optimizes construction sequencing in complex geotechnical projects.

Digital Twin for Geotechnical Asset Management and Predictive Maintenance

Digital twin technology in geotechnics offers real-time, dynamic modeling of subsurface conditions, surpassing traditional Building Information Modeling (BIM) by integrating sensor data and predictive analytics for continuous monitoring and management of geotechnical assets. This enables precise predictive maintenance by forecasting potential failures and optimizing asset lifespan through data-driven decision making. The real-time synchronization between physical geotechnical structures and their digital counterparts enhances risk mitigation and operational efficiency in infrastructure projects.

Interoperability and Collaboration: Challenges and Solutions

Digital twin technology and Building Information Modeling (BIM) in geotechnics face interoperability challenges due to differing data formats and real-time data integration requirements. Solutions focus on adopting open standards like IFC (Industry Foundation Classes) and integrating APIs to enable seamless data exchange and collaborative workflows between geotechnical models and BIM environments. Enhanced cloud-based platforms and digital twin frameworks improve collaboration by providing dynamic updates and centralized data access for multidisciplinary teams.

Case Studies: Digital Twin vs BIM in Geotechnical Engineering

Case studies in geotechnical engineering demonstrate that Digital Twins offer dynamic, real-time monitoring and simulation capabilities surpassing traditional BIM models, enabling proactive risk management and asset optimization. While BIM provides detailed static representations during design and construction phases, Digital Twins integrate live sensor data and predictive analytics for continuous lifecycle management of geotechnical assets. Projects such as tunnel excavation and slope stability analysis highlight Digital Twins' superior ability to adapt to changing subsurface conditions compared to BIM's static data environment.

Future Trends and Innovation in Geotechnical Digitalization

Digital twin technology in geotechnics offers dynamic, real-time monitoring and simulation of subsurface conditions, surpassing traditional BIM's static, design-focused data models by integrating sensor data and predictive analytics. Future trends emphasize AI-driven geotechnical risk assessment, automated data assimilation, and cloud-based collaboration enhancing digital twins' adaptability and precision. Innovations in geotechnical digitalization include the fusion of IoT-enabled site instrumentation with digital twins, enabling proactive maintenance and resilience planning for infrastructure foundations and earthworks.

Geotechnical data integration

Digital twin technology enhances geotechnical data integration beyond BIM by providing real-time monitoring, dynamic simulations, and continuous updates for more accurate subsurface modeling and risk assessment.

Parametric soil modeling

Parametric soil modeling in geotechnics leverages Digital Twin technology for real-time, dynamic simulation and monitoring, surpassing traditional BIM's static data representation by integrating continuous sensor data and adaptive soil behavior analysis.

Subsurface digital replication

Digital twins in geotechnics provide dynamic, real-time subsurface digital replication integrating sensor data for continuous monitoring, while BIM offers static, design-phase models primarily focused on above-ground construction elements.

Ground movement simulation

Digital twins provide dynamic, real-time ground movement simulations in geotechnics by integrating live sensor data, surpassing BIM's static, design-focused modeling capabilities.

Sensor-driven geotechnical monitoring

Digital twin technology enhances geotechnical monitoring by integrating real-time sensor data for dynamic simulations, whereas BIM primarily offers static construction models without continuous sensor-driven updates.

Real-time geospatial analytics

Digital twin technology integrates real-time geospatial analytics in geotechnics, providing dynamic, data-driven insights beyond the static, design-focused models of BIM (Building Information Modeling).

Geomaterial behavior virtualization

Digital twin technology surpasses BIM in geotechnics by enabling real-time virtualization of geomaterial behavior through dynamic data integration and predictive analytics for enhanced subsurface condition monitoring.

Predictive ground performance modeling

Digital twin technology enhances predictive ground performance modeling in geotechnics by providing real-time data integration and dynamic simulations that surpass the static data and design-focused capabilities of traditional Building Information Modeling (BIM).

Geotechnical asset lifecycle management

Digital twin technology enhances geotechnical asset lifecycle management by providing real-time monitoring, predictive analytics, and dynamic simulation beyond the static, design-focused capabilities of Building Information Modeling (BIM).

Earth-structure interaction analysis

Digital twin technology enhances Earth-structure interaction analysis in geotechnics by providing real-time data integration and dynamic simulation beyond the static, model-based capabilities of BIM (Building Information Modeling).

Digital twin vs BIM (Building Information Modeling) in geotechnics Infographic

njnir.com

njnir.com