Geotextiles and geomembranes serve distinct functions in geological engineering, with geotextiles primarily designed for filtration, separation, and reinforcement, while geomembranes provide impermeable barriers for containment and waterproofing. Geotextiles are typically permeable fabrics that allow water flow and soil stabilization, whereas geomembranes are synthetic liners made from materials like HDPE or PVC, offering high resistance to chemical and environmental degradation. Selecting between geotextiles and geomembranes depends on project requirements such as drainage needs, soil compatibility, and containment integrity.

Table of Comparison

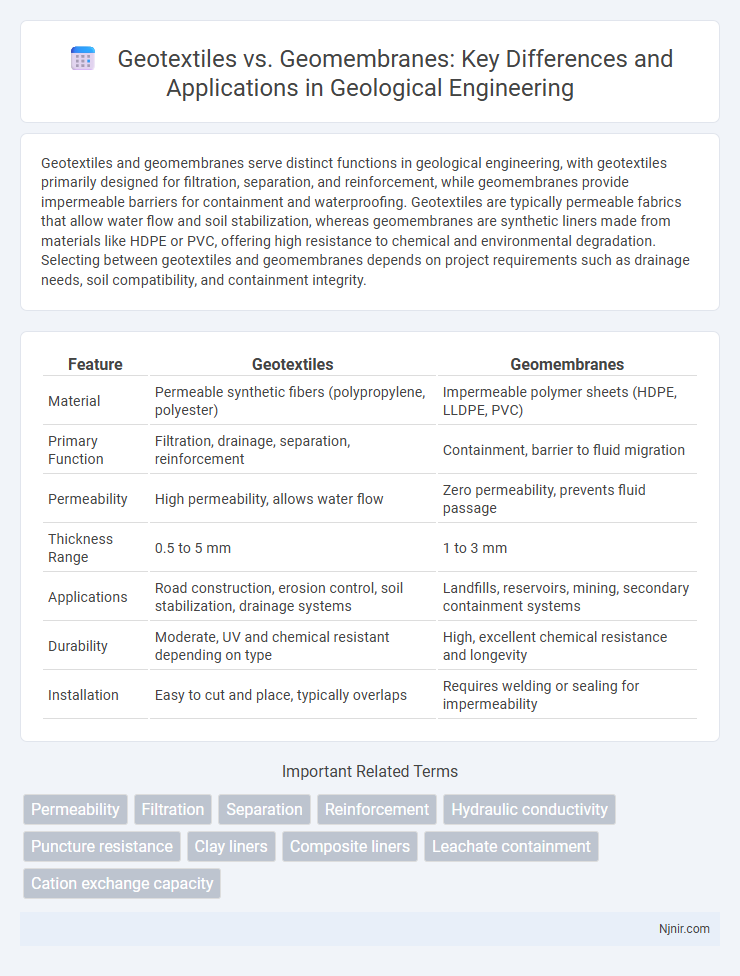

| Feature | Geotextiles | Geomembranes |

|---|---|---|

| Material | Permeable synthetic fibers (polypropylene, polyester) | Impermeable polymer sheets (HDPE, LLDPE, PVC) |

| Primary Function | Filtration, drainage, separation, reinforcement | Containment, barrier to fluid migration |

| Permeability | High permeability, allows water flow | Zero permeability, prevents fluid passage |

| Thickness Range | 0.5 to 5 mm | 1 to 3 mm |

| Applications | Road construction, erosion control, soil stabilization, drainage systems | Landfills, reservoirs, mining, secondary containment systems |

| Durability | Moderate, UV and chemical resistant depending on type | High, excellent chemical resistance and longevity |

| Installation | Easy to cut and place, typically overlaps | Requires welding or sealing for impermeability |

Introduction to Geotextiles and Geomembranes

Geotextiles are permeable fabrics used in civil engineering to separate, filter, reinforce, protect, or drain soil, enhancing soil stability and erosion control in construction projects. Geomembranes are impermeable synthetic liners or membranes primarily utilized for containment and barrier applications, preventing fluid migration in landfills, water reservoirs, and environmental protection systems. Both materials play crucial roles in geotechnical engineering, with geotextiles facilitating soil interaction and geomembranes offering robust impermeability for containment.

Material Composition and Properties

Geotextiles are typically made from synthetic fibers such as polypropylene or polyester, offering permeability, flexibility, and durability for filtration, separation, and reinforcement in soil applications. Geomembranes consist of impermeable materials like high-density polyethylene (HDPE) or polyvinyl chloride (PVC), providing an effective barrier for containment and lining systems in environmental protection projects. The key difference lies in geotextiles allowing water flow through their porous structure, whereas geomembranes serve as impermeable barriers to fluid migration.

Functional Differences: Filtration vs Containment

Geotextiles primarily serve filtration and separation functions by allowing water to pass while preventing soil movement, crucial in drainage and erosion control applications. Geomembranes focus on containment, providing an impermeable barrier to prevent fluid migration, commonly used in landfills, ponds, and mining operations. The key functional differentiation lies in geotextiles facilitating fluid flow and structural support, whereas geomembranes ensure leak-proof isolation.

Applications in Geological Engineering

Geotextiles serve critical roles in geological engineering by providing soil stabilization, filtration, and drainage in applications such as road construction, embankments, and retaining walls. Geomembranes offer impermeable barriers essential for landfill liners, water reservoirs, and contamination prevention in mining sites. Selecting between geotextiles and geomembranes depends on project requirements for reinforcement, filtration, or containment within subsurface and environmental engineering contexts.

Installation Methods and Techniques

Geotextile installation involves unrolling the material over prepared surfaces, ensuring proper overlap of 0.3 to 0.6 meters to maintain filtration and separation functions, with stakes or pins used to secure placement and prevent displacement. Geomembrane installation requires careful seaming through thermal welding or extrusion welding techniques to ensure a continuous, impermeable barrier, with panels positioned using cranes or rollers to avoid wrinkles or damage. Both materials demand site-specific preparation, including surface smoothing and debris removal, to optimize performance and extend durability in civil engineering applications.

Performance in Diverse Soil Conditions

Geotextiles exhibit superior permeability and filtration properties, making them ideal for drainage and soil stabilization in granular and cohesive soils. Geomembranes provide impermeable barriers, excelling in containment applications within contaminated or highly permeable soils. Performance varies as geotextiles allow water flow while preventing soil migration, whereas geomembranes effectively prevent fluid transmission under diverse soil conditions.

Durability and Lifespan

Geotextiles typically exhibit high durability with lifespans ranging from 10 to 50 years depending on environmental conditions and UV exposure, offering resistance to punctures and tears in soil stabilization applications. Geomembranes, often made from materials like HDPE or PVC, provide enhanced impermeability and chemical resistance, with lifespans extending up to 50 years or more under ideal conditions. The choice between geotextiles and geomembranes depends on project requirements for durability against mechanical stress versus impermeability in containment systems.

Environmental Impact and Sustainability

Geotextiles, typically made from natural or synthetic fibers, offer environmental benefits by enabling soil stabilization and erosion control with biodegradability options that reduce landfill waste. Geomembranes, composed mainly of impermeable polymers like HDPE, provide robust containment for hazardous materials, preventing soil and groundwater contamination but may present sustainability challenges due to limited recyclability. Selecting geosynthetics involves balancing biocompatibility and longevity to minimize ecological footprints while enhancing infrastructure durability in environmental engineering projects.

Cost Analysis and Economic Considerations

Geotextiles generally offer lower initial costs compared to geomembranes due to simpler manufacturing processes and wider availability. However, the long-term economic benefits of geomembranes often surpass those of geotextiles in applications requiring impermeability and durability, such as landfill liners or containment systems, resulting in reduced maintenance and replacement expenses. Cost analysis must include lifecycle factors, project-specific environmental conditions, and performance requirements to determine the most cost-effective solution between geotextiles and geomembranes.

Selection Criteria for Geological Projects

Selection criteria for geological projects emphasize the distinct functions of geotextiles and geomembranes; geotextiles excel in filtration, drainage, and soil stabilization due to their permeability and tensile strength, while geomembranes provide impermeable barriers crucial for containment and leak prevention in waste and water management applications. Project-specific factors such as soil type, hydraulic conductivity, load conditions, and environmental exposure dictate the appropriate material choice, ensuring performance longevity and cost efficiency. Compliance with standards like ASTM D5101 for geotextiles and ASTM D5199 for geomembranes further guides selection by validating product durability and functionality under site conditions.

Permeability

Geotextiles typically offer high permeability allowing water flow and filtration, whereas geomembranes are designed to be impermeable barriers that prevent fluid passage.

Filtration

Geotextiles provide effective filtration by allowing water to pass while retaining soil particles, whereas geomembranes serve primarily as impermeable barriers without filtration capabilities.

Separation

Geotextiles provide effective soil separation by allowing water passage while preventing soil mixing, whereas geomembranes serve as impermeable barriers primarily for containment rather than separation.

Reinforcement

Geotextiles enhance soil reinforcement through tensile strength and filtration properties, while geomembranes primarily provide impermeable barriers with limited reinforcement capabilities.

Hydraulic conductivity

Geotextiles exhibit higher hydraulic conductivity facilitating water flow and drainage, whereas geomembranes possess extremely low hydraulic conductivity serving as impermeable barriers to fluid migration.

Puncture resistance

Geotextiles provide moderate puncture resistance suitable for soil stabilization, while geomembranes offer superior puncture resistance essential for high-impact containment applications.

Clay liners

Clay liners provide natural low permeability for containment, while geotextiles improve soil reinforcement and filtration, and geomembranes offer superior impermeability and chemical resistance in landfill liner systems.

Composite liners

Composite liners combine geotextiles' filtration and separation properties with geomembranes' impermeable barriers to enhance landfill containment and prevent fluid migration.

Leachate containment

Geotextiles enhance leachate containment by providing filtration and drainage, while geomembranes serve as impermeable barriers to prevent leachate migration in landfill liners.

Cation exchange capacity

Geotextiles typically have lower cation exchange capacity compared to geomembranes, which are engineered with specialized materials to enhance ion retention and control in environmental engineering applications.

Geotextiles vs Geomembranes Infographic

njnir.com

njnir.com