Geothermal drilling targets heat reservoirs beneath the Earth's surface to harness renewable energy, requiring techniques that manage high temperatures and corrosive fluids unlike conventional oil drilling. While oil drilling primarily focuses on extracting hydrocarbons from sedimentary rock formations, geothermal wells demand precision to prevent reservoir depletion and ensure sustainable heat extraction. Both drilling types utilize advanced technologies, but geothermal projects prioritize environmental impact and long-term resource viability over immediate fuel production.

Table of Comparison

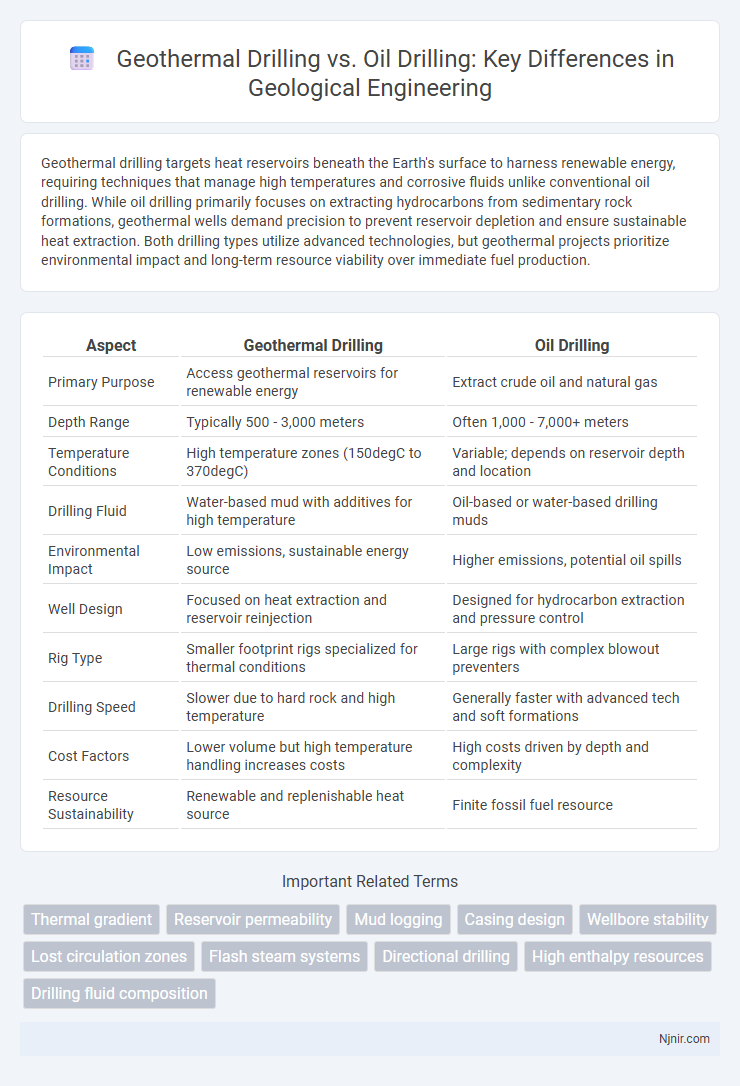

| Aspect | Geothermal Drilling | Oil Drilling |

|---|---|---|

| Primary Purpose | Access geothermal reservoirs for renewable energy | Extract crude oil and natural gas |

| Depth Range | Typically 500 - 3,000 meters | Often 1,000 - 7,000+ meters |

| Temperature Conditions | High temperature zones (150degC to 370degC) | Variable; depends on reservoir depth and location |

| Drilling Fluid | Water-based mud with additives for high temperature | Oil-based or water-based drilling muds |

| Environmental Impact | Low emissions, sustainable energy source | Higher emissions, potential oil spills |

| Well Design | Focused on heat extraction and reservoir reinjection | Designed for hydrocarbon extraction and pressure control |

| Rig Type | Smaller footprint rigs specialized for thermal conditions | Large rigs with complex blowout preventers |

| Drilling Speed | Slower due to hard rock and high temperature | Generally faster with advanced tech and soft formations |

| Cost Factors | Lower volume but high temperature handling increases costs | High costs driven by depth and complexity |

| Resource Sustainability | Renewable and replenishable heat source | Finite fossil fuel resource |

Overview of Geothermal Drilling and Oil Drilling

Geothermal drilling involves penetrating the Earth's crust to access heat reservoirs for renewable energy production, typically targeting depths between 1,000 to 3,000 meters. Oil drilling focuses on extracting hydrocarbons from sedimentary rock formations, often requiring deeper wells exceeding 5,000 meters to reach oil-bearing strata. Both methods employ rotary drilling technology, but geothermal drilling emphasizes environmental sustainability and thermal extraction, while oil drilling centers on hydrocarbon recovery and reservoir pressure management.

Key Geological Considerations in Both Drilling Methods

Geothermal drilling requires targeting heat reservoirs often located in volcanic or tectonically active regions with high subsurface temperatures, demanding detailed analysis of rock permeability and thermal conductivity. Oil drilling focuses on identifying sedimentary basins with porous and permeable rock formations such as sandstone and limestone, rich in hydrocarbons, necessitating seismic surveys and reservoir characterization. Both methods must assess subsurface pressure regimes and fault structures to ensure well stability and optimize extraction efficiency.

Drilling Technologies: Comparative Techniques

Geothermal drilling employs specialized techniques such as directional drilling and enhanced casing materials to withstand high temperatures and corrosive fluids, contrasting with oil drilling, which utilizes advanced rotary drilling and blowout preventers designed for high-pressure hydrocarbon reservoirs. Air or foam drilling fluids are often preferred in geothermal drilling to minimize formation damage, whereas oil drilling predominantly uses mud-based fluids for well control and lubrication. Innovations like coiled tubing and real-time monitoring improve precision in both fields, but geothermal drilling requires materials and technologies optimized for sustained thermal conditions.

Resource Characteristics: Heat vs. Hydrocarbon

Geothermal drilling targets thermal energy stored in hot rock formations, relying on the earth's consistent heat flow to generate renewable power. Oil drilling extracts hydrocarbons trapped in porous rock reservoirs, which are finite and governed by complex geological accumulations of oil and natural gas. The key distinction lies in geothermal energy's sustainability due to heat replenishment versus oil's depletion as a non-renewable resource.

Environmental Impact Assessment

Geothermal drilling typically results in lower greenhouse gas emissions, reduced land disturbance, and minimal water contamination compared to oil drilling, which often involves significant risks of oil spills, air pollution, and habitat disruption. Environmental Impact Assessments for geothermal projects emphasize sustainable resource management and long-term ecosystem balance, whereas oil drilling assessments must address the potential for severe environmental degradation and climate change contributions. The assessment process for geothermal drilling prioritizes renewable energy benefits and mitigates subsurface risks, contrasting with the high-impact extraction and pollution challenges inherent in oil drilling operations.

Well Design and Construction Differences

Geothermal drilling well design prioritizes withstanding high temperatures and corrosive fluids by using specialized casing materials and thermal insulation techniques, whereas oil drilling focuses on managing high pressure zones and hydrocarbon containment with robust blowout preventers and multi-stage casing strings. Cementing in geothermal wells requires temperature-resistant formulations to maintain integrity at elevated subsurface temperatures, contrasting with oil wells where cement primarily ensures zonal isolation under varying pressure regimes. Drill bit selection also diverges, with geothermal wells utilizing harder materials like tungsten carbide to penetrate hot, abrasive rock formations compared to the variety of bit types optimized for diverse sedimentary environments in oil drilling.

Economic Factors and Cost Analysis

Geothermal drilling typically incurs higher upfront costs due to advanced technology and specialized equipment, but offers lower operational expenses and long-term economic benefits through sustainable energy production. Oil drilling involves fluctuating costs driven by volatile crude prices and requires continuous investment in exploration and extraction, impacting overall profitability. Economic analysis must account for geothermal's stable, renewable output against oil's market-dependent revenue streams and environmental compliance costs.

Operational Challenges and Risks

Geothermal drilling faces operational challenges such as high-temperature rock formations and corrosive fluids that can damage equipment and complicate well stability. In contrast, oil drilling often contends with hydrocarbon-rich environments posing blowout risks and complex pressure management issues. Both drilling types require specialized techniques for mitigating reservoir uncertainty and controlling formation damage to ensure safe and efficient extraction.

Regulatory and Safety Standards

Geothermal drilling adheres to strict environmental regulations emphasizing sustainable resource management and minimal surface disturbance, often governed by agencies like the Environmental Protection Agency (EPA) in the United States. Oil drilling regulations prioritize preventing hydrocarbon spills and controlling blowouts, with oversight from bodies such as the Bureau of Safety and Environmental Enforcement (BSEE). Both sectors implement rigorous safety standards including well integrity testing and emergency response protocols to mitigate risks inherent in drilling operations.

Future Trends in Subsurface Drilling Technologies

Future trends in subsurface drilling technologies emphasize automation, real-time data analytics, and advanced materials to enhance efficiency and reduce environmental impact in both geothermal and oil drilling. Geothermal drilling increasingly adopts modular rigs and AI-driven monitoring to optimize drilling in complex geothermal reservoirs, while oil drilling invests in enhanced directional drilling and managed pressure drilling to access deeper and more challenging hydrocarbon reserves. Integration of sustainable practices and hybrid technologies will drive innovations, enabling more precise subsurface targeting and minimizing operational risks across both industries.

Thermal gradient

Geothermal drilling targets areas with high thermal gradients typically above 40degC/km to efficiently harness Earth's heat, whereas oil drilling focuses on sedimentary basins where thermal gradients vary widely and are less critical for extraction.

Reservoir permeability

Geothermal drilling requires higher reservoir permeability to efficiently extract heat, whereas oil drilling often targets reservoirs with varied permeability optimized for hydrocarbon flow.

Mud logging

Mud logging in geothermal drilling requires specialized sensors to monitor high-temperature fluids and gases, whereas oil drilling mud logging primarily focuses on hydrocarbon detection and formation evaluation.

Casing design

Geothermal drilling casing design prioritizes high temperature and corrosion resistance to withstand extreme subsurface environments, whereas oil drilling casing primarily focuses on pressure containment and zonal isolation in hydrocarbon reservoirs.

Wellbore stability

Geothermal drilling faces greater challenges in maintaining wellbore stability due to higher temperatures and chemically reactive fluids compared to oil drilling.

Lost circulation zones

Lost circulation zones in geothermal drilling often present greater challenges than in oil drilling due to higher thermal gradients and fractured rock formations that increase fluid loss risks.

Flash steam systems

Flash steam geothermal drilling involves extracting high-temperature steam by depressurizing hot water from geothermal reservoirs, offering a cleaner and more sustainable alternative to traditional oil drilling that targets hydrocarbon extraction.

Directional drilling

Directional drilling in geothermal projects typically requires more precise temperature and pressure management compared to oil drilling due to the extreme thermal environments encountered.

High enthalpy resources

High enthalpy geothermal drilling targets superheated steam or hot water reservoirs above 150degC for renewable energy, requiring specialized techniques distinct from oil drilling, which focuses on extracting hydrocarbons from sedimentary rock formations.

Drilling fluid composition

Geothermal drilling fluid composition prioritizes high-temperature stability and scaling resistance, while oil drilling fluids focus on viscosity control and hydrocarbon compatibility.

Geothermal drilling vs Oil drilling Infographic

njnir.com

njnir.com