Grouting techniques involve injecting fluid materials into soil or rock to improve strength and reduce permeability, commonly using cement, chemical, or resin grouts tailored to site conditions. Jet grouting, a specialized method, employs high-pressure jets to erode and mix in-situ soil with grout, forming engineered columns of improved ground with enhanced load-bearing capacity. While traditional grouting is effective for sealing and stabilizing, jet grouting provides greater precision and versatility for complex ground conditions and deep soil treatment.

Table of Comparison

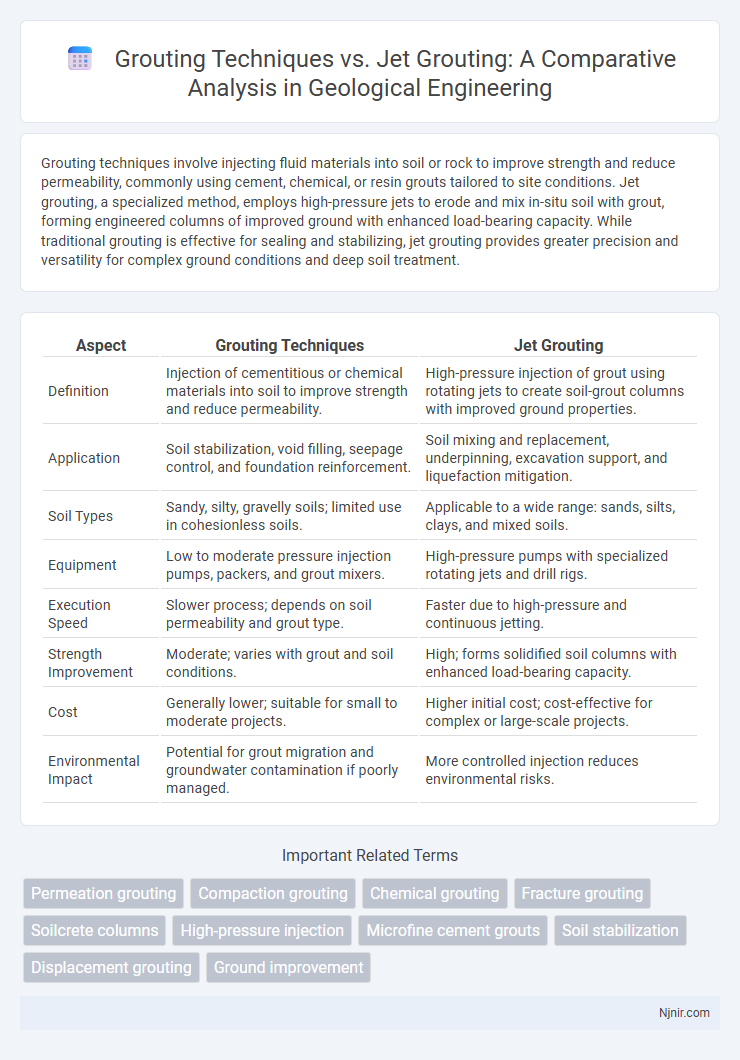

| Aspect | Grouting Techniques | Jet Grouting |

|---|---|---|

| Definition | Injection of cementitious or chemical materials into soil to improve strength and reduce permeability. | High-pressure injection of grout using rotating jets to create soil-grout columns with improved ground properties. |

| Application | Soil stabilization, void filling, seepage control, and foundation reinforcement. | Soil mixing and replacement, underpinning, excavation support, and liquefaction mitigation. |

| Soil Types | Sandy, silty, gravelly soils; limited use in cohesionless soils. | Applicable to a wide range: sands, silts, clays, and mixed soils. |

| Equipment | Low to moderate pressure injection pumps, packers, and grout mixers. | High-pressure pumps with specialized rotating jets and drill rigs. |

| Execution Speed | Slower process; depends on soil permeability and grout type. | Faster due to high-pressure and continuous jetting. |

| Strength Improvement | Moderate; varies with grout and soil conditions. | High; forms solidified soil columns with enhanced load-bearing capacity. |

| Cost | Generally lower; suitable for small to moderate projects. | Higher initial cost; cost-effective for complex or large-scale projects. |

| Environmental Impact | Potential for grout migration and groundwater contamination if poorly managed. | More controlled injection reduces environmental risks. |

Introduction to Grouting Techniques in Geological Engineering

Grouting techniques in geological engineering involve the injection of cementitious or chemical mixtures into soil or rock formations to enhance strength, reduce permeability, and control groundwater flow. Jet grouting, a specialized method, utilizes high-velocity jets to erode and mix in-situ soil with grout, creating soilcrete columns with superior load-bearing capacity and improved ground stability. Compared to traditional grouting, jet grouting offers greater precision and adaptability in complex geological conditions, making it essential for deep foundation support and ground improvement projects.

Fundamentals of Conventional Grouting Methods

Conventional grouting techniques primarily involve permeation, compaction, and chemical injection methods to stabilize soil and reduce permeability by filling voids with cement or chemical mixtures. These methods depend on low-pressure injection, ensuring grout migration through soil pores without soil displacement, making them suitable for granular soils with sufficient permeability. In contrast, jet grouting employs high-pressure jets to erode and mix soil in situ, forming cemented soil columns with enhanced strength and reduced permeability, ideal for challenging ground conditions where conventional grouting is less effective.

Overview and Principles of Jet Grouting

Jet grouting is an advanced soil stabilization technique that uses high-velocity jets of water, air, or grout to erode and mix in-situ soil with cement-based grout, creating a solidified column or block. Unlike traditional grouting methods, which rely on permeation or compaction, jet grouting employs hydraulic cutting technology to achieve higher precision and greater control over ground improvement. It offers enhanced versatility for ground reinforcement in complex soil conditions, deep foundations, and underpinning applications.

Material Types Used in Grouting vs Jet Grouting

Grouting techniques commonly utilize cement-based, chemical, and resin materials that vary in viscosity and setting times to fill voids and improve soil properties. Jet grouting primarily employs a high-pressure injection of cementitious slurries, often mixed with bentonite or polymers, to create engineered soil columns with enhanced strength and impermeability. Material selection in jet grouting is critical for achieving desired ground stabilization and typically involves more specialized mixtures compared to conventional grouting.

Equipment and Technology Differences

Grouting techniques typically use low-pressure pumps and specialized grout mixers to inject cementitious or chemical materials into soil or rock formations, relying on permeability to fill voids. Jet grouting employs high-pressure rotary cutting tools combined with jetting nozzles that simultaneously erode and mix in-situ soil with grout, creating a cemented soilcrete column. The technology differences emphasize conventional pumps versus integrated rotary drilling and high-pressure injection systems specific to jet grouting.

Application Areas in Geological Engineering

Grouting techniques are widely applied in soil stabilization, seepage control, and foundation reinforcement within geological engineering, particularly suited for cohesive soils and shallow subsurface conditions. Jet grouting offers superior adaptability in complex ground conditions, including fractured rock and heterogeneous soils, enabling precise soil mixing and improvement at greater depths. Both methods play critical roles in infrastructure projects, with jet grouting favored for deep foundation underpinning, tunnel sealing, and ground improvement in challenging geological settings.

Performance Comparison: Strength and Permeability

Jet grouting outperforms conventional grouting techniques in both strength and permeability control due to its ability to create highly uniform and dense soil-cement columns. While traditional grouting methods often result in variable strength and inconsistent permeability reduction, jet grouting achieves superior ground improvement by disintegrating and mixing in-situ soil with grout under high pressure. This process yields significantly higher compressive strength and lower permeability, making jet grouting the preferred choice for critical foundations and water cutoff applications.

Environmental Impact and Safety Considerations

Grouting techniques vary in environmental impact, with conventional grouting often producing less soil disturbance but potential chemical leaching, whereas jet grouting involves high-pressure injection that can cause greater ground displacement and increased risk of contaminant spread. Safety considerations for jet grouting require stringent monitoring due to the high-pressure machinery and potential for soil fracturing, while traditional grouting tends to pose lower immediate mechanical risks but requires careful handling of grout materials to prevent toxic exposure. Both methods demand adherence to environmental regulations and risk assessments to minimize ecological damage and ensure worker safety throughout the ground improvement process.

Cost Analysis: Grouting vs Jet Grouting

Grouting techniques generally offer a lower initial cost compared to jet grouting, making them cost-effective for smaller or less complex soil stabilization projects. Jet grouting, while more expensive due to specialized equipment and higher material consumption, provides superior soil improvement and greater versatility in challenging ground conditions, often reducing long-term maintenance costs. Comprehensive cost analysis must consider project scale, soil type, required strength, and potential savings from increased durability and reduced remediation when choosing between grouting and jet grouting methods.

Selection Criteria and Case Studies

Grouting techniques vary widely, with selection criteria focused on soil type, permeability, project depth, and environmental impact, whereas jet grouting excels in applications requiring high precision and strength in heterogeneous ground conditions. Case studies highlight traditional permeation grouting used successfully in sandy soils for leakage control, while jet grouting demonstrates superior performance in stabilizing weak or mixed soils during tunneling and foundation underpinning projects. Optimal method choice depends on factors such as in-situ soil characterization, project scale, cost considerations, and desired mechanical properties post-treatment.

Permeation grouting

Permeation grouting enhances soil stability by injecting low-viscosity grout to fill voids without soil displacement, unlike jet grouting which uses high-pressure jets to mix grout and soil, causing disturbance and creating a soil-grout composite.

Compaction grouting

Compaction grouting uses low-mobility, stiff grout to displace and densify loose soils by injecting it under pressure, contrasting with jet grouting which mixes and replaces soil using high-velocity jets, making compaction grouting ideal for ground stabilization and void filling.

Chemical grouting

Chemical grouting enhances soil stability by injecting reactive chemicals to fill voids and bind particles, offering precise permeability control compared to the mechanical soil displacement and mixing method of jet grouting.

Fracture grouting

Fracture grouting enhances soil stabilization by injecting low-viscosity grout to create controlled fissures, contrasting with jet grouting's high-pressure soil mixing that forms cemented columns.

Soilcrete columns

Soilcrete columns created by jet grouting provide superior soil stabilization and load-bearing capacity compared to traditional grouting techniques due to their enhanced mixing and compaction of in-situ soils.

High-pressure injection

High-pressure injection in jet grouting offers superior soil stabilization and deeper, more precise reinforcement compared to traditional grouting techniques by using pressurized fluids to create a solidified soil column.

Microfine cement grouts

Microfine cement grouts provide superior penetration and strength in grouting techniques compared to jet grouting, enabling effective soil stabilization in fine-grained and low-permeability soils.

Soil stabilization

Jet grouting enhances soil stabilization by injecting high-pressure cement grout to create solidified soil columns, offering deeper and more uniform ground improvement compared to traditional grouting techniques.

Displacement grouting

Displacement grouting, a key technique in grouting methods, injects grout under pressure to physically displace and stabilize surrounding soil, whereas jet grouting uses high-velocity jets to erode and mix soil with grout for in-situ solidification.

Ground improvement

Jet grouting offers superior ground improvement by creating highly uniform, cemented soil columns that enhance load-bearing capacity and reduce permeability compared to traditional grouting techniques.

Grouting techniques vs Jet grouting Infographic

njnir.com

njnir.com