The European Pressurized Reactor (EPR) offers enhanced safety features and higher power output compared to the AP1000, utilizing a robust double containment structure and advanced passive safety systems. In contrast, the AP1000 emphasizes modular construction and simplicity, reducing capital costs and construction time through standardized design and passive safety mechanisms. Both reactors represent significant advancements in nuclear engineering but cater to different strategic priorities in efficiency, safety, and cost-effectiveness.

Table of Comparison

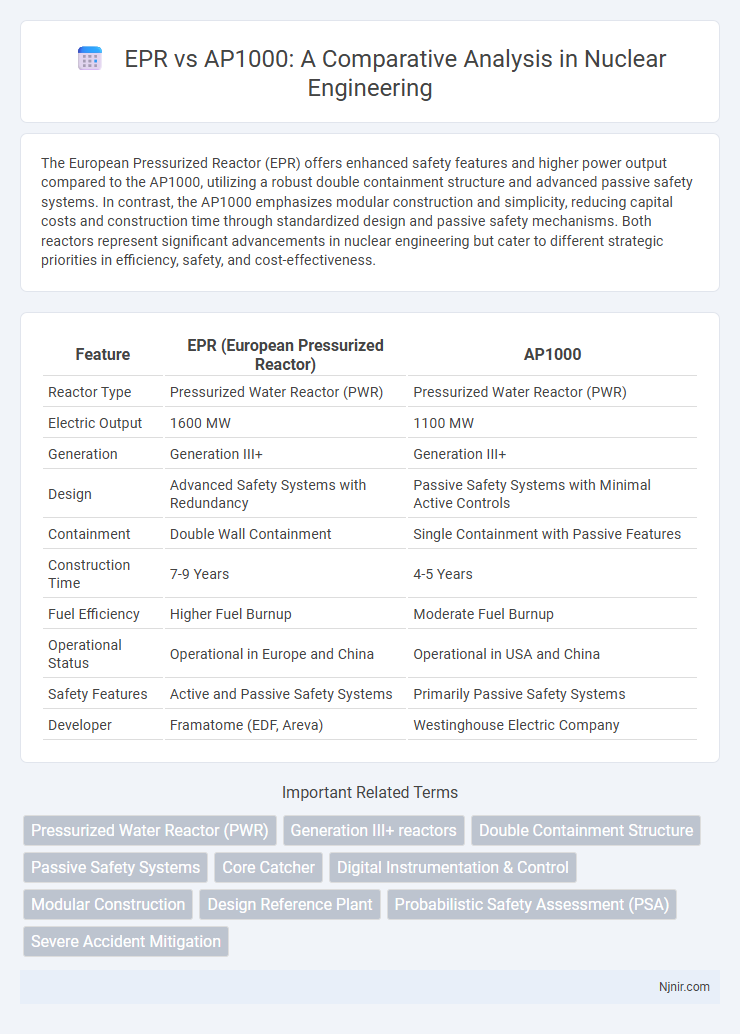

| Feature | EPR (European Pressurized Reactor) | AP1000 |

|---|---|---|

| Reactor Type | Pressurized Water Reactor (PWR) | Pressurized Water Reactor (PWR) |

| Electric Output | 1600 MW | 1100 MW |

| Generation | Generation III+ | Generation III+ |

| Design | Advanced Safety Systems with Redundancy | Passive Safety Systems with Minimal Active Controls |

| Containment | Double Wall Containment | Single Containment with Passive Features |

| Construction Time | 7-9 Years | 4-5 Years |

| Fuel Efficiency | Higher Fuel Burnup | Moderate Fuel Burnup |

| Operational Status | Operational in Europe and China | Operational in USA and China |

| Safety Features | Active and Passive Safety Systems | Primarily Passive Safety Systems |

| Developer | Framatome (EDF, Areva) | Westinghouse Electric Company |

Introduction to EPR and AP1000 Nuclear Reactors

The EPR (European Pressurized Reactor) is a third-generation pressurized water reactor designed for enhanced safety, featuring a power output of approximately 1,600 MW and advanced passive safety systems. The AP1000, developed by Westinghouse, is a Generation III+ reactor emphasizing simplicity and passive safety, with a power capacity around 1,117 MW and modular construction methods. Both reactors represent state-of-the-art nuclear technology aimed at improving efficiency and safety compared to earlier designs.

Historical Development of EPR and AP1000 Designs

The EPR (European Pressurized Reactor) was developed by Areva and EDF, combining advanced safety features from previous French and German reactor designs, with its conceptualization beginning in the early 1990s to meet post-Chernobyl safety standards. The AP1000, designed by Westinghouse, emerged in the late 1990s as a Generation III+ reactor focusing on passive safety systems to enhance reliability and simplify operation compared to earlier PWRs. Both designs reflect significant evolution in nuclear technology, addressing lessons learned from past incidents and regulatory changes to improve safety, efficiency, and cost-effectiveness in contemporary nuclear power generation.

Reactor Core Design and Technology Comparison

The EPR (European Pressurized Reactor) features a core design with 241 fuel assemblies and advanced safety systems that include double containment and four redundant safety trains, enhancing its passive safety capabilities. In comparison, the AP1000 utilizes 157 fuel assemblies arranged in a simpler core design optimized for modular construction, incorporating passive safety systems that rely on natural circulation without active components for emergency cooling. Both reactors employ pressurized water reactor technology but differ significantly in fuel assembly configuration and safety system architecture, reflecting their distinct approaches to core design and operational efficiency.

Safety Features and Innovation

The EPR reactor integrates advanced safety features such as a double-wall containment structure and a core catcher designed to mitigate severe accidents, enhancing passive safety systems that reduce reliance on operator intervention. In contrast, the AP1000 emphasizes passive safety innovation through natural circulation for cooling and fewer moving parts, enabling automatic shutdown and cooling without external power or human action in emergencies. Both designs represent state-of-the-art advancements in nuclear safety, with the EPR prioritizing robust containment and accident management, while the AP1000 focuses on simplicity and passive safety mechanisms to prevent core damage.

Power Output and Efficiency

The EPR (European Pressurized Reactor) delivers a power output of approximately 1650 MW electric with a thermal efficiency around 37%, utilizing advanced pressure vessel technology and a high steam pressure system. In contrast, the AP1000 offers a power output of about 1117 MW electric and achieves thermal efficiency close to 33%, leveraging passive safety features and simplified design to optimize operational performance. The EPR's higher power output and slightly greater efficiency reflect its larger core size and advanced steam conditions, making it suitable for large-scale energy production.

Construction and Deployment Challenges

The EPR (European Pressurized Reactor) has faced significant construction delays and cost overruns due to complex design features and stringent regulatory requirements, leading to extended project timelines in Finland and France. In contrast, the AP1000, designed by Westinghouse, emphasizes modular construction to streamline assembly, yet its deployment encountered challenges such as welding quality issues and supply chain disruptions in the U.S. and China. Both reactor types illustrate the difficulties in balancing advanced safety systems with efficient construction practices, impacting their global deployment schedules.

Licensing and Regulatory Compliance

EPR (European Pressurized Reactor) and AP1000 are advanced nuclear reactor designs subject to rigorous licensing and regulatory compliance processes in multiple jurisdictions. EPR has obtained regulatory approvals in the EU, China, and Finland, demonstrating adherence to stringent European nuclear safety standards, while AP1000 has been certified by the U.S. Nuclear Regulatory Commission (NRC) and approved for construction in China and the United States. Both reactors emphasize compliance with international safety guidelines, but AP1000 benefits from its modular design, potentially streamlining regulatory reviews and construction permits compared to the more complex EPR system.

Operational Performance and Track Records

The EPR reactor features advanced digital control systems and has demonstrated stable performance with a high capacity factor exceeding 90% in European commercial operations. The AP1000 leverages passive safety systems and modular construction, achieving efficient operational uptime with over 85% capacity factor in U.S. units. Both reactors show strong safety records, but the AP1000 benefits from simplified designs that reduce human error and maintenance downtime.

Cost Analysis and Economic Considerations

The EPR (European Pressurized Reactor) generally incurs higher upfront capital costs compared to the AP1000 due to its more complex design and larger size, often exceeding $10 billion per unit. The AP1000's modular construction approach and standardized components reduce on-site labor expenses and shorten construction timelines, leading to estimated costs around $6-8 billion per unit. Economic considerations favor the AP1000 for utilities seeking lower initial investment and faster return on capital, while the EPR's higher capacity and operational flexibility may offer improved long-term revenue potential despite higher initial financial risk.

Future Prospects in the Global Nuclear Market

The EPR (European Pressurized Reactor) and AP1000 represent advanced Generation III+ nuclear technologies with distinct global market prospects shaped by regional preferences and regulatory environments. EPR's higher power output and robust safety features position it favorably for countries emphasizing large-scale electricity generation and stringent safety standards, while the AP1000's modular design and shorter construction timelines appeal to markets valuing cost efficiency and rapid deployment. Future growth in the global nuclear market will likely depend on government policies supporting clean energy transitions, with both reactors competing to meet rising demand for low-carbon baseload power amid evolving regulatory frameworks and supply chain dynamics.

Pressurized Water Reactor (PWR)

The EPR and AP1000 are advanced Pressurized Water Reactor (PWR) designs, with the EPR emphasizing higher power output and enhanced safety features, while the AP1000 focuses on passive safety systems and simplified construction.

Generation III+ reactors

The EPR and AP1000 are Generation III+ reactors distinguished by EPR's higher power output of 1650 MW and advanced safety features, while AP1000 emphasizes modular construction and passive safety systems for enhanced efficiency and reduced costs.

Double Containment Structure

The EPR features a robust double containment structure with a thicker inner wall and reinforced concrete compared to the AP1000's simpler double containment designed primarily for pressure retention and leak prevention.

Passive Safety Systems

The EPR uses active safety systems relying on powered equipment, whereas the AP1000 features advanced passive safety systems that operate without operator intervention or external power for up to 72 hours.

Core Catcher

The EPR reactor features a robust core catcher designed to contain and cool molten core material during a severe accident, whereas the AP1000 employs a passive core cooling system integrated with its core catcher to enhance safety without active intervention.

Digital Instrumentation & Control

The EPR features a fully integrated digital instrumentation and control system with advanced fault diagnostics, while the AP1000 employs a simplified and modular digital control architecture emphasizing passive safety and reduced complexity.

Modular Construction

The EPR employs extensive modular construction with large, pre-fabricated sections to accelerate onsite assembly and improve quality control, while the AP1000 uses a highly standardized modular design featuring smaller, factory-built modules to enhance flexibility and reduce construction time.

Design Reference Plant

The EPR Design Reference Plant emphasizes enhanced safety features with a focus on a double-wall containment structure, whereas the AP1000 Design Reference Plant prioritizes passive safety systems and modular construction for streamlined assembly and reduced onsite labor.

Probabilistic Safety Assessment (PSA)

The EPR features a more comprehensive Probabilistic Safety Assessment (PSA) with lower core damage frequency (CDF) and enhanced severe accident mitigation compared to the AP1000, reflecting advanced safety system redundancies and diverse safety strategies.

Severe Accident Mitigation

EPR reactors feature enhanced severe accident mitigation with double containment and core catcher systems, while AP1000 designs emphasize passive safety systems including passive core cooling and containment cooling to effectively manage severe accident scenarios.

EPR vs AP1000 Infographic

njnir.com

njnir.com