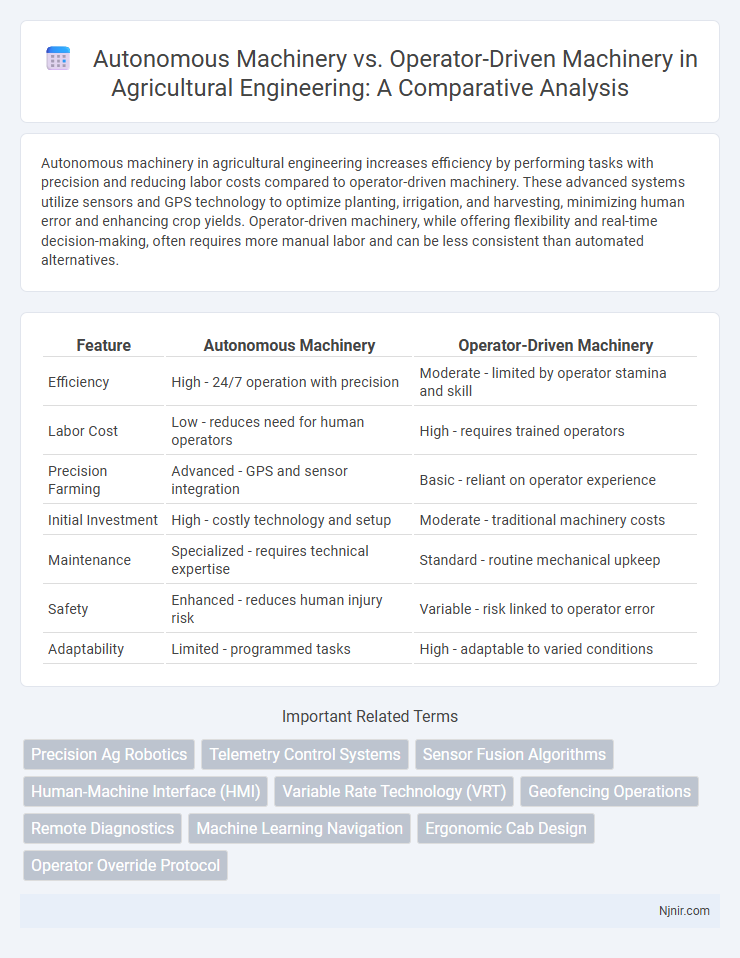

Autonomous machinery in agricultural engineering increases efficiency by performing tasks with precision and reducing labor costs compared to operator-driven machinery. These advanced systems utilize sensors and GPS technology to optimize planting, irrigation, and harvesting, minimizing human error and enhancing crop yields. Operator-driven machinery, while offering flexibility and real-time decision-making, often requires more manual labor and can be less consistent than automated alternatives.

Table of Comparison

| Feature | Autonomous Machinery | Operator-Driven Machinery |

|---|---|---|

| Efficiency | High - 24/7 operation with precision | Moderate - limited by operator stamina and skill |

| Labor Cost | Low - reduces need for human operators | High - requires trained operators |

| Precision Farming | Advanced - GPS and sensor integration | Basic - reliant on operator experience |

| Initial Investment | High - costly technology and setup | Moderate - traditional machinery costs |

| Maintenance | Specialized - requires technical expertise | Standard - routine mechanical upkeep |

| Safety | Enhanced - reduces human injury risk | Variable - risk linked to operator error |

| Adaptability | Limited - programmed tasks | High - adaptable to varied conditions |

Introduction to Autonomous and Operator-Driven Machinery

Autonomous machinery utilizes advanced sensors, artificial intelligence, and machine learning algorithms to perform tasks without human intervention, increasing efficiency and reducing operational risks. Operator-driven machinery relies on manual control by skilled operators, offering flexibility and real-time decision-making in complex environments. Industries such as agriculture, mining, and manufacturing are increasingly integrating autonomous systems to optimize productivity while maintaining operator-driven equipment for precision and adaptability.

Key Technologies Powering Autonomous Machinery

Key technologies powering autonomous machinery include advanced sensors such as LiDAR, radar, and high-resolution cameras that enable precise environment mapping and obstacle detection. Machine learning algorithms and real-time data processing facilitate adaptive decision-making and efficient navigation without human intervention. Integration of GPS and IoT connectivity ensures robust communication, monitoring, and control, distinguishing autonomous machinery from operator-driven equipment.

Comparative Efficiency: Automation vs. Human Operation

Autonomous machinery consistently demonstrates higher efficiency compared to operator-driven machinery by reducing human error and enabling continuous operation without fatigue. Advanced sensors and AI algorithms optimize task execution, resulting in faster completion times and improved precision. In contrast, human-operated machinery is limited by operator skill levels, attention span, and physical endurance, often leading to variability in productivity and increased downtime.

Cost Implications: Initial Investment and Long-Term Savings

Autonomous machinery requires a higher initial investment due to advanced sensors, AI technology, and integration costs, but it offers significant long-term savings through reduced labor expenses and increased operational efficiency. Operator-driven machinery incurs lower upfront costs but often results in higher ongoing expenses linked to wages, human error, and maintenance. Evaluating total cost of ownership highlights that autonomous systems can deliver greater return on investment by minimizing downtime and optimizing resource usage over time.

Labor Dynamics and Workforce Impact

Autonomous machinery significantly reduces the demand for manual labor by automating repetitive and hazardous tasks, leading to workforce displacement in certain sectors while creating new opportunities in robotics maintenance and programming. Operator-driven machinery relies heavily on skilled labor, maintaining steady employment but exposing workers to higher physical risks and fatigue. The shift towards autonomous systems accelerates skill transformation, emphasizing digital literacy and technical expertise over traditional manual operation.

Safety Considerations and Risk Management

Autonomous machinery significantly reduces human exposure to hazardous environments, lowering the risk of operator-related accidents through advanced sensors, real-time monitoring, and automated emergency protocols. Operator-driven machinery requires continuous manual oversight, increasing the likelihood of human error, fatigue, and injury, necessitating strict adherence to safety training and protective measures. Effective risk management in autonomous systems involves rigorous validation, cybersecurity safeguards, and regular maintenance to mitigate malfunctions, while operator-driven equipment emphasizes safety audits and ergonomic design to protect workers.

Precision and Consistency in Agricultural Tasks

Autonomous machinery in agriculture delivers higher precision by utilizing GPS-guided systems and real-time data analytics, reducing human error and ensuring uniform application of seeds, fertilizers, and pesticides. Operator-driven machinery often depends on the skill and experience of the driver, introducing variability in task execution and potentially inconsistent field coverage. Consistency in autonomous equipment enhances crop yield quality and resource efficiency through repeatable, exact operations regardless of external conditions.

Environmental Sustainability and Resource Optimization

Autonomous machinery enhances environmental sustainability by reducing fuel consumption through precise operations and minimizing emissions with optimized energy use. Operator-driven machinery often leads to inconsistent resource utilization and higher waste production due to human error and less efficient control. Advanced sensors and AI algorithms in autonomous systems enable real-time adjustments, significantly improving resource optimization and lowering the overall ecological footprint in industrial and agricultural applications.

Maintenance, Troubleshooting, and Reliability

Autonomous machinery typically requires less frequent maintenance due to advanced sensors and predictive diagnostics that preempt mechanical failures, enhancing overall reliability compared to operator-driven machinery. Troubleshooting in autonomous systems leverages integrated software diagnostics and remote monitoring, enabling faster issue identification and resolution without the need for manual inspection. Conversely, operator-driven machinery depends heavily on routine manual checks and human expertise for maintenance and troubleshooting, which can increase downtime and reduce operational reliability.

Future Trends and Adoption Challenges in Agricultural Machinery

Autonomous machinery in agriculture is rapidly advancing with innovations in AI, machine learning, and sensor technology, enabling precise crop monitoring, automated planting, and yield optimization. Despite promising efficiency gains and labor cost reductions, adoption challenges include high initial investment, integration with existing farm systems, and concerns over data security and operator trust. Future trends indicate greater hybrid models combining operator oversight with AI-driven automation to maximize productivity while addressing regulatory and ethical considerations.

Precision Ag Robotics

Precision Ag Robotics significantly enhances farming efficiency and accuracy by deploying autonomous machinery that outperforms traditional operator-driven equipment in tasks such as planting, crop monitoring, and harvesting.

Telemetry Control Systems

Telemetry Control Systems enhance autonomous machinery by enabling real-time data transmission and remote operation, significantly improving precision, efficiency, and safety compared to operator-driven machinery.

Sensor Fusion Algorithms

Sensor fusion algorithms enhance autonomous machinery by integrating data from multiple sensors to improve accuracy, reliability, and decision-making compared to operator-driven machinery.

Human-Machine Interface (HMI)

Autonomous machinery utilizes advanced Human-Machine Interface (HMI) technologies such as adaptive touchscreens and voice recognition to reduce operator input, enhance safety, and improve efficiency compared to traditional operator-driven machinery relying on manual controls.

Variable Rate Technology (VRT)

Variable Rate Technology (VRT) enhances autonomous machinery's efficiency by enabling precise, site-specific input application, outperforming operator-driven machinery in reducing waste and optimizing crop yields.

Geofencing Operations

Geofencing operations enhance safety and efficiency by enabling autonomous machinery to operate within predefined virtual boundaries, reducing human error compared to operator-driven machinery.

Remote Diagnostics

Remote diagnostics in autonomous machinery enables real-time fault detection and predictive maintenance, significantly reducing downtime compared to operator-driven machinery.

Machine Learning Navigation

Machine learning navigation enables autonomous machinery to optimize route efficiency, adapt to dynamic environments, and reduce human error compared to operator-driven machinery.

Ergonomic Cab Design

Ergonomic cab design in autonomous machinery enhances operator comfort and reduces fatigue compared to operator-driven machinery by integrating adjustable seating, intuitive controls, and advanced monitoring systems.

Operator Override Protocol

Operator Override Protocol in autonomous machinery ensures immediate manual control transfer to human operators, enhancing safety and operational decision-making compared to operator-driven machinery.

autonomous machinery vs operator-driven machinery Infographic

njnir.com

njnir.com