On-farm biogas generators utilize organic waste materials to produce renewable energy, reducing reliance on fossil fuels and lowering greenhouse gas emissions. These systems offer cost savings over time through the valorization of agricultural by-products and improved energy security for rural farms. Fossil fuel generators, while reliable and widely available, contribute to environmental pollution and fluctuating fuel costs, making biogas a more sustainable alternative in modern agricultural engineering.

Table of Comparison

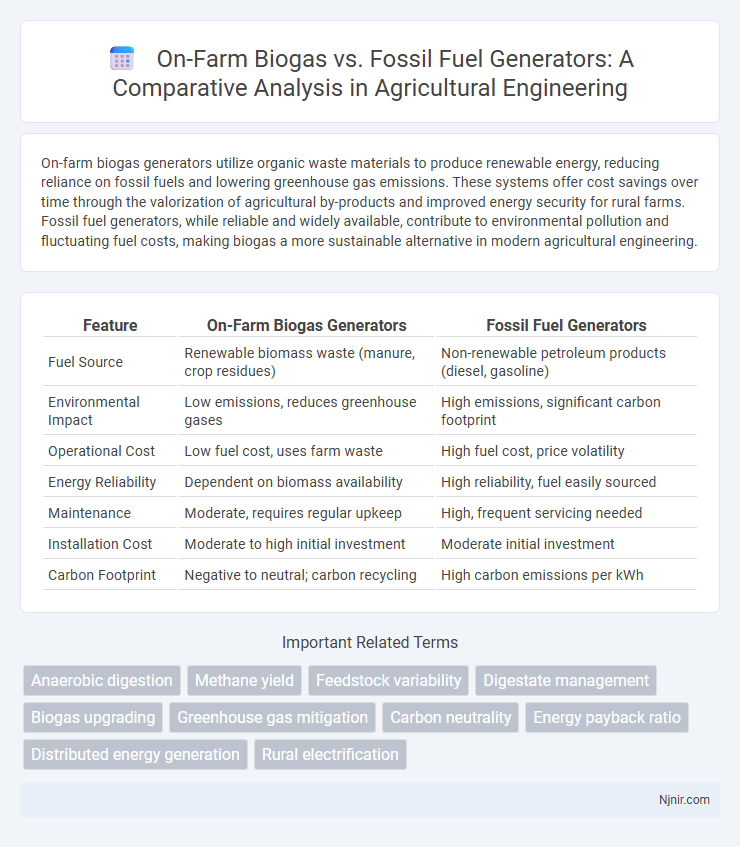

| Feature | On-Farm Biogas Generators | Fossil Fuel Generators |

|---|---|---|

| Fuel Source | Renewable biomass waste (manure, crop residues) | Non-renewable petroleum products (diesel, gasoline) |

| Environmental Impact | Low emissions, reduces greenhouse gases | High emissions, significant carbon footprint |

| Operational Cost | Low fuel cost, uses farm waste | High fuel cost, price volatility |

| Energy Reliability | Dependent on biomass availability | High reliability, fuel easily sourced |

| Maintenance | Moderate, requires regular upkeep | High, frequent servicing needed |

| Installation Cost | Moderate to high initial investment | Moderate initial investment |

| Carbon Footprint | Negative to neutral; carbon recycling | High carbon emissions per kWh |

Introduction to On-Farm Energy Solutions

On-farm biogas systems convert organic waste into renewable energy, reducing greenhouse gas emissions and dependence on fossil fuels. These systems enhance energy self-sufficiency by producing methane-rich biogas used for electricity and heat generation. Compared to fossil fuel generators, on-farm biogas offers sustainable, cost-effective energy solutions while improving waste management and environmental impact.

How On-Farm Biogas Systems Work

On-farm biogas systems capture methane produced from the anaerobic digestion of livestock manure, crop residues, and organic waste, converting it into renewable energy. This methane is then used to generate electricity or heat on-site, reducing reliance on fossil fuel generators, which burn non-renewable fuels like diesel or natural gas. By utilizing biogas, farmers can lower greenhouse gas emissions and improve energy efficiency while managing waste sustainably.

Fossil Fuel Generators: Mechanisms and Applications

Fossil fuel generators operate by combusting hydrocarbons such as diesel or gasoline to produce mechanical energy that drives electrical generators, delivering consistent power output independent of weather conditions. These generators are widely used for backup power, remote site electricity, and high-demand industrial applications due to their high energy density and quick startup times. Despite their reliability, fossil fuel generators emit greenhouse gases like CO2 and NOx, contributing to environmental pollution and increasing operational costs over time.

Comparative Analysis: Efficiency and Output

On-farm biogas generators typically achieve energy conversion efficiencies between 25% and 40%, while fossil fuel generators range from 30% to 45%. Biogas systems utilize organic waste, producing renewable energy and reducing greenhouse gas emissions, though their output can be less consistent due to feedstock variability. Fossil fuel generators offer higher and more stable power output but contribute significantly to carbon dioxide emissions and resource depletion.

Environmental Impact: Emissions and Sustainability

On-farm biogas generators significantly reduce greenhouse gas emissions by capturing methane from organic waste, unlike fossil fuel generators that release carbon dioxide and other pollutants from burning nonrenewable resources. The renewable nature of biogas supports sustainable energy practices by recycling agricultural waste and minimizing reliance on finite fossil fuels. This shift contributes to lower carbon footprints and promotes long-term environmental health in agricultural communities.

Cost Considerations: Installation and Operation

On-farm biogas generators have higher initial installation costs due to the need for biodigesters and feedstock preparation systems, but they benefit from low ongoing fuel expenses by utilizing organic waste. Fossil fuel generators typically require lower upfront investments, yet incur significant and volatile operational costs driven by fuel prices and maintenance. Over time, biogas systems offer improved cost efficiency and energy independence, particularly for farms with consistent access to biomass feedstock.

Energy Security and Farm Resilience

On-farm biogas generators enhance energy security by utilizing organic waste materials, reducing dependence on unstable fossil fuel supply chains and volatile markets. These systems provide consistent, renewable energy, increasing farm resilience against power outages and fuel price fluctuations. By integrating biogas technology, farms achieve greater operational stability while minimizing environmental impact compared to fossil fuel generators.

Maintenance and Technical Requirements

On-farm biogas generators demand regular monitoring of feedstock quality, anaerobic digester stability, and gas cleaning systems to prevent corrosion and clogging, while fossil fuel generators primarily require periodic oil changes, filter replacements, and spark plug maintenance. Biogas systems involve managing biological processes which necessitate technical expertise in microbiology and engineering, whereas fossil fuel generators rely more on mechanical and electrical maintenance skills. Effective upkeep of biogas units can yield longer operational lifespans and lower emissions, whereas fossil fuel generators often face higher downtime due to mechanical wear and more frequent servicing intervals.

Policy Incentives and Regulatory Challenges

Policy incentives for on-farm biogas generators include feed-in tariffs, tax credits, and renewable energy certificates aimed at promoting sustainable energy production and reducing greenhouse gas emissions. Fossil fuel generators face stricter environmental regulations and carbon pricing mechanisms that increase operational costs but often lack equivalent subsidies promoting cleaner alternatives. Regulatory challenges for biogas systems involve complex permitting processes and grid interconnection standards, while fossil fuel generators encounter tightening emission limits and potential phase-out policies under climate action plans.

Future Trends in On-Farm Energy Generation

On-farm biogas generators are rapidly gaining traction as sustainable energy solutions, leveraging agricultural waste to produce renewable energy while reducing greenhouse gas emissions. Future trends indicate increased integration of advanced anaerobic digestion technologies and smart grid connectivity to optimize energy efficiency and storage on farms. These developments position on-farm biogas systems as economically viable and environmentally preferable alternatives to fossil fuel generators, driving the transition toward carbon-neutral agricultural operations.

Anaerobic digestion

Anaerobic digestion in on-farm biogas generators converts organic waste into renewable energy, significantly reducing greenhouse gas emissions compared to fossil fuel generators.

Methane yield

On-farm biogas generators produce methane yields up to 60% higher than fossil fuel generators, significantly enhancing renewable energy efficiency and reducing greenhouse gas emissions.

Feedstock variability

On-farm biogas generators face feedstock variability challenges unlike fossil fuel generators, which rely on consistent fuel supplies for stable energy production.

Digestate management

On-farm biogas generators produce nutrient-rich digestate that can be efficiently managed as organic fertilizer, reducing reliance on chemical fertilizers and minimizing environmental pollution compared to fossil fuel generators.

Biogas upgrading

On-farm biogas upgrading enhances methane purity to over 95%, significantly increasing energy efficiency and reducing CO2 emissions compared to fossil fuel generators.

Greenhouse gas mitigation

On-farm biogas generators reduce greenhouse gas emissions by converting organic waste into renewable energy, offering a sustainable alternative to high-emission fossil fuel generators.

Carbon neutrality

On-farm biogas generators achieve carbon neutrality by recycling methane from organic waste, reducing greenhouse gas emissions compared to fossil fuel generators that emit carbon dioxide from non-renewable sources.

Energy payback ratio

On-farm biogas generators typically achieve an energy payback ratio of 5 to 7, significantly higher than fossil fuel generators, which often have ratios below 1 due to low efficiency and high energy input requirements.

Distributed energy generation

On-farm biogas generators provide sustainable, low-emission distributed energy generation compared to centralized fossil fuel generators, enhancing energy resilience and reducing carbon footprint in rural agricultural settings.

Rural electrification

On-farm biogas generators provide sustainable, cost-effective rural electrification by utilizing locally available organic waste, reducing reliance on expensive and polluting fossil fuel generators.

On-farm biogas vs fossil fuel generators Infographic

njnir.com

njnir.com