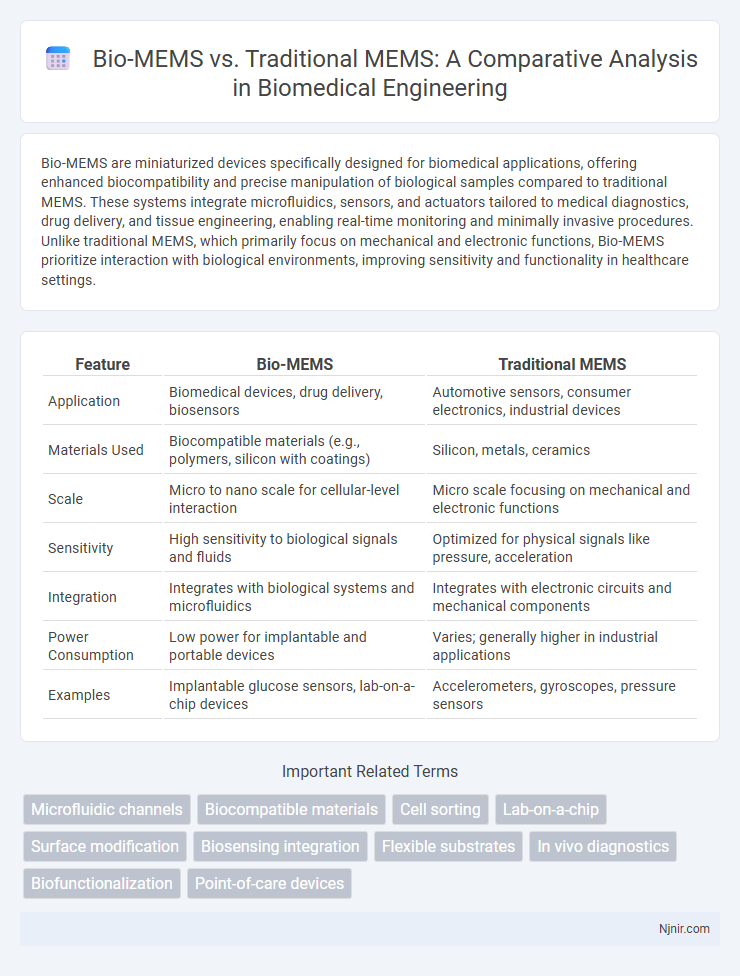

Bio-MEMS are miniaturized devices specifically designed for biomedical applications, offering enhanced biocompatibility and precise manipulation of biological samples compared to traditional MEMS. These systems integrate microfluidics, sensors, and actuators tailored to medical diagnostics, drug delivery, and tissue engineering, enabling real-time monitoring and minimally invasive procedures. Unlike traditional MEMS, which primarily focus on mechanical and electronic functions, Bio-MEMS prioritize interaction with biological environments, improving sensitivity and functionality in healthcare settings.

Table of Comparison

| Feature | Bio-MEMS | Traditional MEMS |

|---|---|---|

| Application | Biomedical devices, drug delivery, biosensors | Automotive sensors, consumer electronics, industrial devices |

| Materials Used | Biocompatible materials (e.g., polymers, silicon with coatings) | Silicon, metals, ceramics |

| Scale | Micro to nano scale for cellular-level interaction | Micro scale focusing on mechanical and electronic functions |

| Sensitivity | High sensitivity to biological signals and fluids | Optimized for physical signals like pressure, acceleration |

| Integration | Integrates with biological systems and microfluidics | Integrates with electronic circuits and mechanical components |

| Power Consumption | Low power for implantable and portable devices | Varies; generally higher in industrial applications |

| Examples | Implantable glucose sensors, lab-on-a-chip devices | Accelerometers, gyroscopes, pressure sensors |

Introduction: Defining Bio-MEMS and Traditional MEMS

Bio-MEMS are microelectromechanical systems designed specifically for biological and medical applications, integrating microfluidics, sensors, and actuators to interact with cells, tissues, or biological molecules. Traditional MEMS encompass a broad range of microscale devices used in industries such as automotive, telecommunications, and consumer electronics, focusing on mechanical, electrical, and optical functionalities without direct biological integration. The distinct feature of Bio-MEMS lies in their biocompatibility and capability to perform precise manipulation and analysis of biological materials at microscale levels.

Materials and Fabrication Techniques

Bio-MEMS utilize biocompatible materials such as polymers like PDMS, hydrogels, and silicon-based substrates tailored for biological environments, while traditional MEMS primarily employ silicon, metals, and ceramics optimized for mechanical and electronic applications. Fabrication techniques for Bio-MEMS often incorporate soft lithography, micro-molding, and surface functionalization to accommodate delicate biological samples and ensure biocompatibility, contrasting with traditional MEMS that rely heavily on photolithography, deep reactive-ion etching (DRIE), and bulk micromachining for high precision and durability. The integration of microfluidics in Bio-MEMS requires specialized materials and fabrication methods to enable fluid manipulation and sensing in biomedical devices, distinguishing them from conventional MEMS focused on inert material properties.

Functional Differences in Device Design

Bio-MEMS devices integrate biological materials and functions such as cell culture, biochemical sensing, and drug delivery, whereas traditional MEMS primarily involve mechanical components like microgears and accelerometers. The design of Bio-MEMS emphasizes biocompatibility, fluidic handling, and chemical specificity, contrasting with traditional MEMS focus on mechanical robustness and electrical performance. Functional differences also include microscale biointerfaces in Bio-MEMS for cellular interactions, absent in conventional MEMS architectures.

Application Areas: Clinical vs Industrial

Bio-MEMS devices excel in clinical applications such as point-of-care diagnostics, drug delivery systems, and biosensing for disease detection, leveraging their biocompatibility and microscale fluid handling. Traditional MEMS are predominantly utilized in industrial sectors for applications including sensors in automotive systems, process control, and environmental monitoring due to their robustness and compatibility with harsh environments. The distinct material requirements and operational conditions define the differentiation in application areas, with Bio-MEMS prioritizing biological integration and Traditional MEMS focusing on mechanical and environmental resilience.

Sensitivity and Selectivity in Sensing

Bio-MEMS exhibit enhanced sensitivity and selectivity compared to Traditional MEMS due to their integration with biological components such as enzymes, antibodies, or cells, enabling precise detection of specific biomolecules at low concentrations. The functionalization of sensing surfaces in Bio-MEMS improves molecular recognition, reducing false positives and increasing response accuracy in complex biological environments. Traditional MEMS rely primarily on physical or chemical transduction mechanisms, which often lack the specificity inherent in biologically functionalized interfaces.

Integration with Biological Systems

Bio-MEMS devices exhibit superior integration with biological systems by utilizing biocompatible materials and microfluidic architectures that mimic physiological environments, enabling precise cellular manipulation and real-time biochemical analysis. Traditional MEMS, designed primarily for mechanical and electronic applications, lack the specialized surface chemistries and fluidic control necessary for seamless interaction with living tissues. The incorporation of sensors and actuators in Bio-MEMS facilitates enhanced biosensing, targeted drug delivery, and tissue engineering, positioning them as pivotal tools in biomedical research and healthcare diagnostics.

Challenges in Biocompatibility and Miniaturization

Bio-MEMS face significant challenges in biocompatibility due to the need for materials that prevent immune response and ensure long-term stability within biological environments, whereas traditional MEMS primarily operate in inert or controlled settings. Miniaturization in Bio-MEMS must accommodate complex biological functions and fluid dynamics, requiring innovative fabrication techniques and materials to maintain functionality at microscale dimensions. These challenges demand interdisciplinary approaches combining materials science, microfabrication, and biomedical engineering to enhance device performance and integration in living systems.

Regulatory and Ethical Considerations

Bio-MEMS devices face stricter regulatory scrutiny due to their direct interaction with biological tissues, requiring compliance with medical device standards such as FDA 510(k) clearance and ISO 13485 certification. Ethical considerations emphasize patient safety, informed consent, and data privacy, distinguishing Bio-MEMS from traditional MEMS that primarily focus on industrial and consumer applications with fewer biological risks. Regulatory frameworks prioritize biocompatibility and long-term effects, reflecting the critical ethical responsibilities unique to Bio-MEMS development and deployment.

Recent Innovations and Future Prospects

Recent innovations in Bio-MEMS have enhanced biocompatibility and miniaturization, enabling precise biosensing and targeted drug delivery, surpassing traditional MEMS primarily used in mechanical and electronic applications. Advances in microfluidics and lab-on-a-chip technologies have revolutionized disease diagnostics and personalized medicine through real-time monitoring and high-throughput analysis. Future prospects include integration with AI for predictive healthcare, widespread deployment in wearable devices, and expansion into regenerative medicine, offering transformative potential beyond traditional MEMS capabilities.

Comparative Performance and Efficiency

Bio-MEMS demonstrate superior biocompatibility and sensitivity compared to Traditional MEMS, enabling enhanced performance in biomedical applications such as drug delivery and diagnostics. The integration of biological components in Bio-MEMS allows for real-time monitoring and precise manipulation at the cellular level, which traditional MEMS cannot achieve with the same efficiency. Energy consumption in Bio-MEMS is often optimized for minimal invasiveness, resulting in greater operational efficiency in vivo relative to conventional MEMS devices.

Microfluidic channels

Bio-MEMS utilize biocompatible materials and precisely engineered microfluidic channels for controlled biological sample manipulation, outperforming traditional MEMS that primarily focus on mechanical or electronic functions with less specialized fluidic design.

Biocompatible materials

Bio-MEMS utilize biocompatible materials such as polymers, hydrogels, and silicon-based substrates to ensure safe interaction with biological systems, whereas traditional MEMS primarily rely on silicon, metals, and ceramics with limited biocompatibility for biomedical applications.

Cell sorting

Bio-MEMS offers enhanced cell sorting precision and biocompatibility compared to traditional MEMS by integrating microfluidic channels with biological sensing elements for real-time cellular analysis.

Lab-on-a-chip

Bio-MEMS technology enhances lab-on-a-chip devices by integrating biocompatible materials and microfluidic channels for precise biological analysis, outperforming traditional MEMS in sensitivity and functionality.

Surface modification

Surface modification in Bio-MEMS utilizes biocompatible coatings and functionalization to enhance cell interaction and sensor sensitivity, whereas Traditional MEMS primarily employs surface treatments for mechanical durability and chemical resistance.

Biosensing integration

Bio-MEMS integrate advanced biocompatible materials and microfluidic components for precise biosensing applications, outperforming traditional MEMS in sensitivity and specificity.

Flexible substrates

Bio-MEMS devices on flexible substrates enable enhanced biocompatibility and conformal integration with biological tissues, unlike traditional MEMS typically fabricated on rigid silicon wafers.

In vivo diagnostics

Bio-MEMS enhance in vivo diagnostics through biocompatible materials and microfluidic integration, enabling real-time, minimally invasive monitoring compared to traditional MEMS.

Biofunctionalization

Bio-MEMS leverage advanced biofunctionalization techniques to enhance biocompatibility and specificity, outperforming Traditional MEMS in applications like medical diagnostics and drug delivery.

Point-of-care devices

Bio-MEMS enhance point-of-care devices by integrating biocompatible materials and microfluidic components for rapid, accurate diagnostics compared to traditional MEMS limited to general mechanical sensing.

Bio-MEMS vs Traditional MEMS Infographic

njnir.com

njnir.com