Biodegradable implants offer the advantage of gradually dissolving in the body, reducing the need for secondary surgeries and minimizing long-term complications associated with metallic implants such as corrosion and stress shielding. These implants promote natural tissue regeneration by providing temporary support during the healing process, contrasting with metallic implants that remain permanently and can interfere with imaging techniques. Advances in material science enable biodegradable implants to match mechanical strength requirements while enhancing biocompatibility and reducing inflammatory responses compared to traditional metallic options.

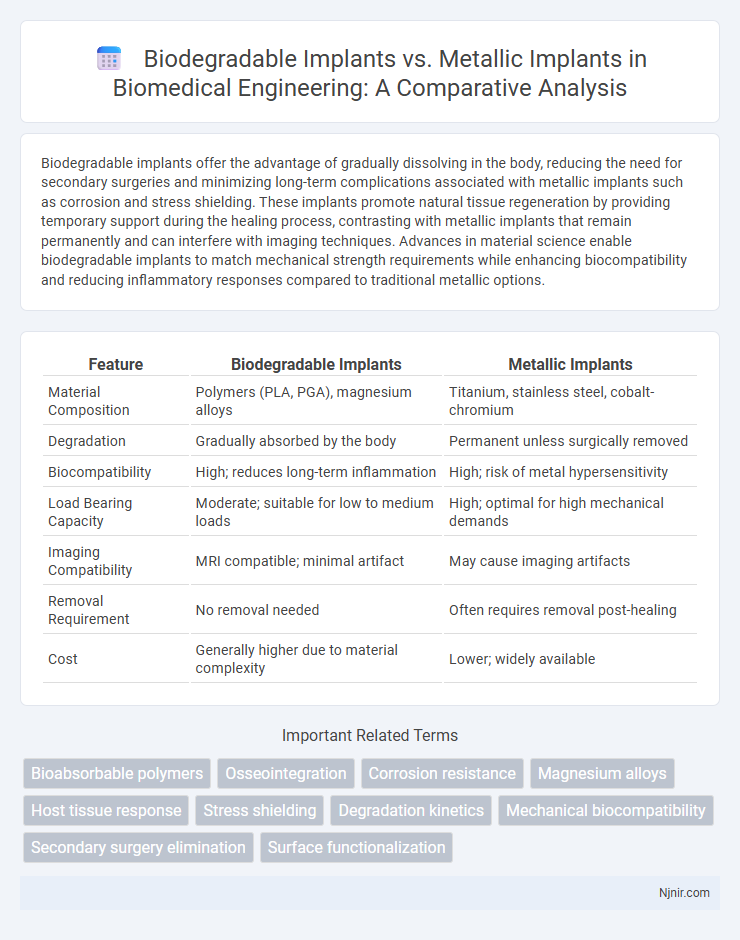

Table of Comparison

| Feature | Biodegradable Implants | Metallic Implants |

|---|---|---|

| Material Composition | Polymers (PLA, PGA), magnesium alloys | Titanium, stainless steel, cobalt-chromium |

| Degradation | Gradually absorbed by the body | Permanent unless surgically removed |

| Biocompatibility | High; reduces long-term inflammation | High; risk of metal hypersensitivity |

| Load Bearing Capacity | Moderate; suitable for low to medium loads | High; optimal for high mechanical demands |

| Imaging Compatibility | MRI compatible; minimal artifact | May cause imaging artifacts |

| Removal Requirement | No removal needed | Often requires removal post-healing |

| Cost | Generally higher due to material complexity | Lower; widely available |

Introduction to Implant Materials in Biomedical Engineering

Biodegradable implants, made from materials such as polylactic acid (PLA) and magnesium alloys, offer the advantage of gradual degradation and absorption by the body, reducing the need for secondary surgeries. In contrast, metallic implants composed of titanium, stainless steel, or cobalt-chromium alloys provide superior mechanical strength and corrosion resistance but remain permanently in the body unless surgically removed. The selection of implant materials in biomedical engineering depends on factors like biocompatibility, mechanical properties, and the intended duration of implantation.

Overview of Biodegradable Implants

Biodegradable implants, primarily made from polymers such as polylactic acid (PLA) and polyglycolic acid (PGA), gradually dissolve in the body, eliminating the need for secondary removal surgery. They offer advantages like reduced long-term complications and promotion of natural tissue regeneration compared to metallic implants, which remain permanently unless surgically extracted. These implants are increasingly used in orthopedic and cardiovascular applications due to their biocompatibility and controlled degradation rates tailored to specific healing processes.

Characteristics of Metallic Implants

Metallic implants exhibit high mechanical strength, corrosion resistance, and excellent biocompatibility, making them ideal for load-bearing orthopedic applications. Common materials include titanium, stainless steel, and cobalt-chromium alloys, valued for their durability and stability within the human body. Despite their long-term functionality, metallic implants may require surgical removal due to potential complications such as stress shielding and allergic reactions.

Biocompatibility and Immune Response

Biodegradable implants exhibit superior biocompatibility by gradually degrading into non-toxic byproducts that minimize chronic inflammation and reduce long-term immune response compared to metallic implants. Metallic implants often provoke a persistent foreign body reaction, triggering fibrous capsule formation and potential hypersensitivity due to corrosion or ion release. The controlled degradation of biodegradable materials supports tissue integration and healing, lowering the risk of immune rejection and improving overall clinical outcomes.

Mechanical Properties and Performance

Biodegradable implants exhibit mechanical properties tailored to degrade over time, providing temporary support with gradual load transfer to healing tissues, whereas metallic implants maintain consistent strength and stiffness for long-term structural stability. The elastic modulus of biodegradable materials more closely matches that of bone, reducing stress shielding compared to metallic implants with higher stiffness. Performance of biodegradable implants includes controlled degradation rates and bioresorption, enhancing tissue regeneration, while metallic implants may require removal surgeries due to permanence and potential for corrosion or metal ion release.

Degradation and Longevity in the Body

Biodegradable implants undergo controlled degradation through hydrolysis or enzymatic activity, gradually being absorbed and eliminated by the body, reducing the need for secondary removal surgery. Metallic implants, primarily composed of titanium or stainless steel, exhibit high mechanical strength and long-term stability without degradation but may cause stress shielding and require removal if complications arise. The selection between biodegradable and metallic implants depends on balancing implant longevity with the desired biological resorption profile for optimal tissue healing.

Clinical Applications and Use Cases

Biodegradable implants offer significant advantages in clinical applications such as orthopedic and cardiovascular surgeries by eliminating the need for removal and reducing long-term complications like infection and implant rejection. These implants are especially beneficial in pediatric cases and fracture fixation where gradual load transfer and bone remodeling are crucial. In contrast, metallic implants remain the standard for load-bearing applications requiring high mechanical strength, such as joint replacements and spinal fixation, due to their durability and proven long-term performance.

Patient Outcomes and Complication Rates

Biodegradable implants reduce long-term complications by eliminating the need for removal surgery, resulting in improved patient comfort and faster recovery times compared to metallic implants. Studies show biodegradable implants lower infection rates and minimize tissue irritation, enhancing overall patient outcomes. In contrast, metallic implants often lead to stress shielding and potential allergic reactions, increasing the risk of complications and extended rehabilitation periods.

Regulatory and Manufacturing Considerations

Biodegradable implants require rigorous biocompatibility and degradation rate assessments to meet regulatory standards, often involving complex clinical trials to ensure safe resorption without adverse tissue reactions. Metallic implants, governed by established standards such as ASTM and ISO, demand stringent material consistency and corrosion resistance evaluations to maintain long-term structural integrity. Manufacturing processes for biodegradable implants emphasize precise polymer synthesis and sterilization methods that preserve bioactivity, whereas metallic implants rely on advanced metallurgical techniques and surface treatments for enhanced durability and osseointegration.

Future Trends and Innovations in Implant Technologies

Future trends in implant technologies emphasize biodegradable implants that eliminate the need for secondary removal surgeries, enhancing patient comfort and reducing healthcare costs. Innovations include the development of smart biodegradable materials with controlled degradation rates and bioactive coatings that promote tissue regeneration. Advances in nanotechnology and 3D printing enable personalized metallic implants with improved biocompatibility and mechanical strength for long-term durability.

Bioabsorbable polymers

Bioabsorbable polymers in biodegradable implants offer controlled degradation and reduced long-term complications compared to traditional metallic implants, enhancing tissue regeneration and eliminating the need for secondary removal surgeries.

Osseointegration

Biodegradable implants enhance osseointegration by gradually transferring load to bone and reducing stress shielding, unlike metallic implants which often cause stress shielding and may interfere with bone remodeling.

Corrosion resistance

Biodegradable implants offer superior corrosion resistance by naturally degrading in the body, eliminating the long-term corrosion risks associated with metallic implants.

Magnesium alloys

Magnesium alloy biodegradable implants offer superior biocompatibility and gradual resorption compared to traditional metallic implants, reducing long-term complications and eliminating the need for surgical removal.

Host tissue response

Biodegradable implants promote favorable host tissue response by gradually degrading and reducing chronic inflammation compared to metallic implants, which often provoke prolonged foreign body reactions.

Stress shielding

Biodegradable implants minimize stress shielding by gradually transferring load to healing bone, unlike metallic implants that often cause bone resorption due to their high stiffness mismatch.

Degradation kinetics

Biodegradable implants exhibit controlled degradation kinetics tailored to tissue healing rates, while metallic implants remain stable without degradation, often requiring removal surgery.

Mechanical biocompatibility

Biodegradable implants offer superior mechanical biocompatibility by gradually transferring load to healing tissue, minimizing stress shielding compared to rigid metallic implants.

Secondary surgery elimination

Biodegradable implants eliminate the need for secondary surgery by naturally dissolving within the body, unlike metallic implants which require removal after healing.

Surface functionalization

Surface functionalization of biodegradable implants enhances biocompatibility and controlled degradation rates, whereas metallic implants benefit from surface coatings that improve corrosion resistance and osseointegration.

biodegradable implants vs metallic implants Infographic

njnir.com

njnir.com