Digital twins enable real-time simulation and monitoring of biomedical devices, offering rapid iteration and precise data analysis without the need for physical fabrication. Physical prototypes provide tangible testing opportunities crucial for validating device performance and biocompatibility in realistic environments. Combining digital twins with physical prototypes enhances design accuracy and accelerates the development of innovative biomedical solutions.

Table of Comparison

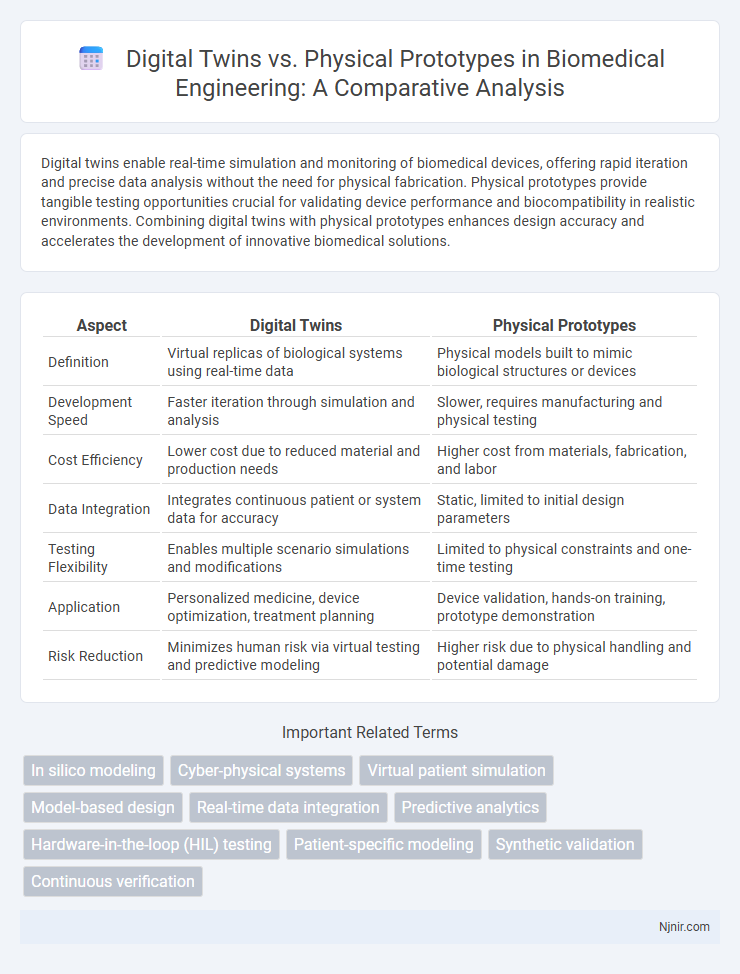

| Aspect | Digital Twins | Physical Prototypes |

|---|---|---|

| Definition | Virtual replicas of biological systems using real-time data | Physical models built to mimic biological structures or devices |

| Development Speed | Faster iteration through simulation and analysis | Slower, requires manufacturing and physical testing |

| Cost Efficiency | Lower cost due to reduced material and production needs | Higher cost from materials, fabrication, and labor |

| Data Integration | Integrates continuous patient or system data for accuracy | Static, limited to initial design parameters |

| Testing Flexibility | Enables multiple scenario simulations and modifications | Limited to physical constraints and one-time testing |

| Application | Personalized medicine, device optimization, treatment planning | Device validation, hands-on training, prototype demonstration |

| Risk Reduction | Minimizes human risk via virtual testing and predictive modeling | Higher risk due to physical handling and potential damage |

Introduction to Digital Twins and Physical Prototypes

Digital twins are virtual replicas of physical objects or systems that use real-time data and simulations to monitor, analyze, and optimize performance throughout the lifecycle. Physical prototypes are tangible models created to test form, fit, and function before mass production, providing hands-on evaluation of design concepts. Digital twins enable continuous feedback and predictive maintenance, while physical prototypes offer direct interaction and validation of material properties.

Core Concepts: Digital Twins Explained

Digital twins are virtual replicas of physical assets that enable real-time monitoring, simulation, and analysis to optimize performance and predict maintenance needs. Unlike physical prototypes, digital twins integrate data from sensors embedded in the actual product or system, allowing continuous synchronization between the digital and physical realms. This core concept enhances decision-making throughout the product lifecycle by providing dynamic insights that physical prototypes cannot offer.

Core Concepts: Physical Prototypes in Biomedical Engineering

Physical prototypes in biomedical engineering serve as tangible models used to test and validate device functionality, safety, and ergonomics before clinical application. These prototypes are essential for hands-on evaluation, enabling iterative design improvements through direct interaction with anatomical simulations or biological materials. Their use helps bridge the gap between theoretical design and real-world use, ensuring compliance with stringent regulatory standards and patient safety requirements.

Key Differences: Digital Twins vs Physical Prototypes

Digital twins provide real-time data integration and dynamic simulation of physical assets, enabling continuous monitoring and predictive analysis, unlike physical prototypes which are static, tangible models used primarily for initial design validation. Digital twins allow rapid iterations and virtual testing across multiple scenarios without material costs, whereas physical prototypes require time-consuming fabrication and physical modifications for each test. The key difference lies in digital twins' ability to mirror real-world behavior through sensors and IoT connectivity, offering enhanced efficiency and scalability compared to traditional physical prototypes.

Applications of Digital Twins in Biomedical Engineering

Digital twins in biomedical engineering enable real-time simulation of physiological processes and personalized treatment planning, significantly enhancing the accuracy of medical device design and patient care. These virtual replicas facilitate preclinical testing, reducing reliance on physical prototypes and accelerating the development of implants, prosthetics, and diagnostic tools. Integration with AI and IoT improves predictive maintenance of medical equipment and supports remote patient monitoring, optimizing healthcare outcomes.

Applications of Physical Prototypes in Healthcare

Physical prototypes in healthcare are crucial for surgical training, allowing medical professionals to practice complex procedures on realistic anatomical models, which improves precision and patient safety. They also serve as essential tools for testing and refining medical devices under real-world conditions before clinical trials, ensuring functionality and compliance with regulatory standards. Furthermore, physical prototypes facilitate patient-specific treatment planning by providing tangible models for preoperative assessment and customized implant design.

Advantages of Digital Twins for Medical Device Development

Digital twins enable real-time simulation and testing of medical devices, significantly reducing development time and costs compared to physical prototypes. They allow for precise virtual modeling of device performance under various conditions, enhancing accuracy and safety without the risks associated with physical trials. This technology facilitates iterative design and personalized device customization, accelerating innovation in medical device development.

Limitations of Physical Prototypes in Biomedical Research

Physical prototypes in biomedical research often face limitations such as high costs, lengthy development times, and restricted scalability for testing diverse scenarios. They may not accurately replicate complex biological systems or patient-specific variations, leading to less precise experiment outcomes. These constraints hinder rapid innovation and personalized medicine advancements compared to digital twin technologies.

Integration and Hybrid Approaches in Biomedicine

Integration of digital twins with physical prototypes in biomedicine enables real-time simulation and analysis of patient-specific conditions, improving diagnostic accuracy and personalized treatment plans. Hybrid approaches combine virtual models with tangible devices, facilitating iterative testing and refinement of medical implants, prosthetics, and surgical tools. This synergy accelerates innovation while reducing costs and risks associated with traditional prototype development in biomedicine.

Future Trends: The Evolving Role of Digital Twins and Physical Prototypes

Digital twins are rapidly transforming product development by enabling real-time simulation, predictive maintenance, and enhanced design optimization, which significantly reduces the need for costly physical prototypes. Future trends show increasing integration of AI and IoT technologies within digital twins, allowing for more accurate and dynamic virtual representations that adapt continuously throughout a product's lifecycle. While physical prototypes remain essential for final validation and tactile feedback, the evolving role of digital twins is expected to streamline innovation cycles and drive smarter, more efficient manufacturing processes.

In silico modeling

In silico modeling in digital twins enables precise virtual testing and optimization of physical prototypes, significantly reducing development time and costs.

Cyber-physical systems

Digital twins enable real-time simulation and monitoring of cyber-physical systems, reducing the need for costly physical prototypes while enhancing design accuracy and system optimization.

Virtual patient simulation

Virtual patient simulation using digital twins enhances medical training and personalized treatment by providing accurate, dynamic models, surpassing the limitations of traditional physical prototypes.

Model-based design

Model-based design leverages digital twins to simulate, test, and optimize product performance virtually, significantly reducing the need for costly and time-consuming physical prototypes.

Real-time data integration

Digital twins enable continuous real-time data integration for precise monitoring and simulation, surpassing physical prototypes limited by static and delayed feedback.

Predictive analytics

Digital twins leverage predictive analytics to simulate real-time performance and forecast potential failures more accurately than traditional physical prototypes.

Hardware-in-the-loop (HIL) testing

Hardware-in-the-loop (HIL) testing integrates digital twin models with physical hardware components to validate system performance, enabling faster iteration and reduced costs compared to traditional physical prototypes.

Patient-specific modeling

Digital twins enable real-time patient-specific modeling by simulating physiological responses more accurately than traditional physical prototypes, enhancing personalized healthcare outcomes.

Synthetic validation

Digital twins enable faster, cost-effective synthetic validation by simulating real-world conditions in a virtual environment, surpassing the time and resource demands of physical prototypes.

Continuous verification

Digital twins enable continuous verification through real-time data synchronization and dynamic simulation, surpassing static physical prototypes in accuracy and efficiency.

Digital twins vs Physical prototypes Infographic

njnir.com

njnir.com