IoT (Internet of Things) primarily targets consumer applications, connecting everyday devices like smart home systems and wearable technology for enhanced convenience and automation. IIoT (Industrial Internet of Things) focuses on industrial environments, leveraging advanced sensors, machine learning, and real-time data analytics to optimize manufacturing processes, improve safety, and increase operational efficiency. The critical distinction lies in IIoT's emphasis on robust, secure, and scalable solutions tailored to complex industrial infrastructures.

Table of Comparison

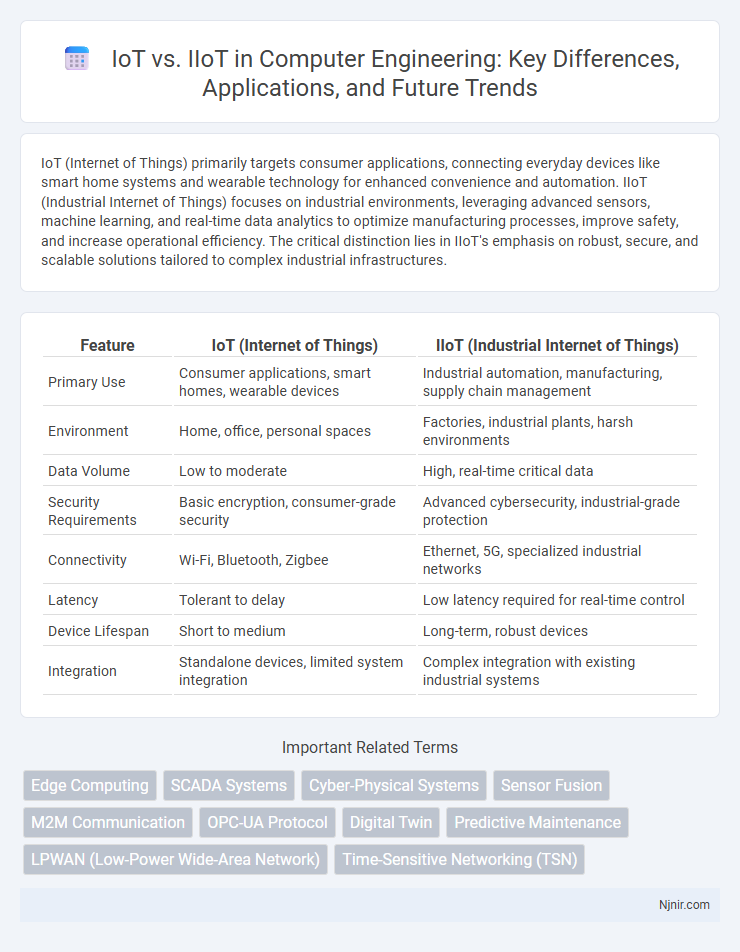

| Feature | IoT (Internet of Things) | IIoT (Industrial Internet of Things) |

|---|---|---|

| Primary Use | Consumer applications, smart homes, wearable devices | Industrial automation, manufacturing, supply chain management |

| Environment | Home, office, personal spaces | Factories, industrial plants, harsh environments |

| Data Volume | Low to moderate | High, real-time critical data |

| Security Requirements | Basic encryption, consumer-grade security | Advanced cybersecurity, industrial-grade protection |

| Connectivity | Wi-Fi, Bluetooth, Zigbee | Ethernet, 5G, specialized industrial networks |

| Latency | Tolerant to delay | Low latency required for real-time control |

| Device Lifespan | Short to medium | Long-term, robust devices |

| Integration | Standalone devices, limited system integration | Complex integration with existing industrial systems |

Introduction to IoT and IIoT

The Internet of Things (IoT) connects everyday devices like smartphones and home appliances to the internet, enabling data exchange and smart automation. In contrast, the Industrial Internet of Things (IIoT) applies similar connectivity concepts specifically to industrial environments, integrating sensors, machines, and control systems to enhance operational efficiency and predictive maintenance. IIoT emphasizes reliability, security, and real-time data analytics to optimize manufacturing, energy, and supply chain processes.

Core Differences Between IoT and IIoT

IoT (Internet of Things) primarily connects consumer devices like smart home gadgets and wearables, focusing on convenience and personal use, while IIoT (Industrial Internet of Things) targets industrial equipment, enhancing operational efficiency and safety in sectors such as manufacturing, energy, and transportation. IIoT systems require robust data analytics, real-time monitoring, and high-security standards to handle critical infrastructure and large-scale industrial processes. The core difference lies in their application scope and complexity, with IIoT emphasizing industrial automation and predictive maintenance, unlike the consumer-oriented applications of IoT.

Key Technologies Powering IoT and IIoT

IoT relies on technologies such as wireless sensor networks, cloud computing, and edge devices to enable seamless connectivity and data exchange across consumer applications. IIoT leverages advanced industrial sensors, machine learning algorithms, and robust cybersecurity protocols to optimize manufacturing processes, predictive maintenance, and real-time analytics. Both IoT and IIoT benefit from developments in 5G networks, AI integration, and big data platforms to enhance scalability and operational efficiency.

Architecture Comparison: IoT vs IIoT

IoT architecture typically consists of interconnected sensors, devices, and cloud platforms designed for consumer applications, emphasizing scalability and ease of integration. IIoT architecture incorporates more robust, industrial-grade hardware, edge computing, and real-time analytics to ensure reliability, security, and low latency in manufacturing environments. The IIoT framework prioritizes interoperability between operational technology (OT) and information technology (IT) systems, enabling advanced process automation and predictive maintenance.

Security Challenges in IoT and IIoT

IoT security challenges revolve around device vulnerability, data privacy risks, and unsecured communication protocols exposing consumer networks to cyberattacks. IIoT security encounters heightened threats due to critical infrastructure integration, where breaches can disrupt industrial operations, cause physical damage, or compromise sensitive operational data. Both IoT and IIoT require robust encryption, continuous monitoring, and advanced anomaly detection to mitigate evolving cybersecurity risks effectively.

Industrial Applications of IIoT

IIoT (Industrial Internet of Things) enhances manufacturing efficiency by integrating smart sensors, connected machinery, and real-time data analytics to optimize production processes. Industrial applications include predictive maintenance, asset tracking, and automated quality control, which reduce downtime and operational costs. Unlike general IoT, IIoT prioritizes robust cybersecurity, scalability, and compliance with industrial standards for mission-critical environments.

Consumer Use Cases for IoT

IoT (Internet of Things) primarily enhances consumer experiences through smart home devices, wearable technology, and connected health monitors, enabling automation and real-time data insights. IIoT (Industrial Internet of Things) focuses on optimizing industrial processes, predictive maintenance, and supply chain management for manufacturing and energy sectors. Consumer use cases for IoT include smart thermostats, security systems, and fitness trackers that improve convenience, safety, and personal health management.

Data Management and Analytics in IoT vs IIoT

Data management in IoT involves handling diverse consumer-generated data from smart devices, focusing on scalability and real-time processing for personalized experiences. In contrast, IIoT emphasizes robust data governance, high-volume industrial sensor data collection, and advanced predictive analytics to optimize operational efficiency and minimize downtime. Analytics in IIoT leverages machine learning and edge computing for real-time anomaly detection and maintenance forecasting, whereas IoT analytics primarily supports user behavior analysis and smart home automation.

Future Trends in IoT and IIoT

Future trends in IoT emphasize enhanced connectivity with 5G integration, widespread adoption of AI-driven analytics, and increased emphasis on data security to support smart cities and consumer devices. In contrast, IIoT is rapidly advancing through edge computing deployment, predictive maintenance powered by machine learning, and the expansion of digital twins to optimize industrial processes and reduce downtime. Both IoT and IIoT are converging towards greater interoperability and real-time data processing to drive innovation across consumer and industrial ecosystems.

Choosing Between IoT and IIoT Solutions

Choosing between IoT and IIoT solutions depends on the application context, as IoT primarily targets consumer-oriented devices for smart homes and personal gadgets, while IIoT focuses on industrial automation, manufacturing processes, and critical infrastructure. IIoT solutions emphasize robust security, real-time data analytics, and integration with industrial control systems, enabling predictive maintenance and enhanced operational efficiency. Evaluating factors such as scalability, latency requirements, and industry-specific compliance helps determine the optimal choice for deploying connected devices and systems.

Edge Computing

Edge computing in IIoT enhances real-time data processing and operational efficiency by analyzing sensor data locally, whereas IoT often relies on cloud-based processing for consumer applications.

SCADA Systems

SCADA systems in IIoT offer enhanced real-time data analytics, industrial-grade security, and seamless integration with legacy equipment compared to traditional IoT implementations.

Cyber-Physical Systems

Cyber-Physical Systems in Industrial Internet of Things (IIoT) integrate advanced sensors, real-time data analytics, and automated control to enhance operational efficiency and safety beyond traditional Internet of Things (IoT) applications.

Sensor Fusion

Sensor fusion in IoT integrates data from diverse sensors for consumer applications, while IIoT employs advanced sensor fusion to enhance industrial automation, predictive maintenance, and real-time operational efficiency.

M2M Communication

M2M communication in IoT enables basic device interactions for consumer applications, while IIoT leverages advanced, secure M2M protocols to optimize industrial automation and real-time data exchange.

OPC-UA Protocol

The OPC-UA protocol enhances IIoT by providing secure, standardized communication and interoperability tailored for industrial environments, unlike general IoT protocols.

Digital Twin

Digital Twin technology in IIoT offers advanced predictive maintenance and real-time asset management capabilities that surpass the consumer-focused applications of IoT.

Predictive Maintenance

Predictive maintenance in IIoT leverages advanced sensor data and machine learning algorithms to optimize industrial equipment performance, surpassing general IoT applications focused on consumer device monitoring.

LPWAN (Low-Power Wide-Area Network)

LPWAN technology enables IoT applications by providing low-power, long-range connectivity while IIoT leverages LPWAN to enhance industrial automation with scalable, secure, and energy-efficient communication networks.

Time-Sensitive Networking (TSN)

Time-Sensitive Networking (TSN) enables Industrial Internet of Things (IIoT) to achieve deterministic, low-latency communication essential for real-time control, unlike general Internet of Things (IoT) that prioritizes scalability over strict timing guarantees.

IoT vs IIoT Infographic

njnir.com

njnir.com