Activated sludge systems offer enhanced treatment efficiency by promoting aerobic microbial growth through continuous aeration and mixing, resulting in rapid organic matter degradation. Trickling filters utilize a fixed-bed microbial biofilm on media over which wastewater is distributed, enabling slower but energy-efficient aerobic treatment. Both methods effectively reduce biochemical oxygen demand (BOD) and suspended solids, but activated sludge systems demand higher operational control and energy input compared to the simpler, low-maintenance trickling filters.

Table of Comparison

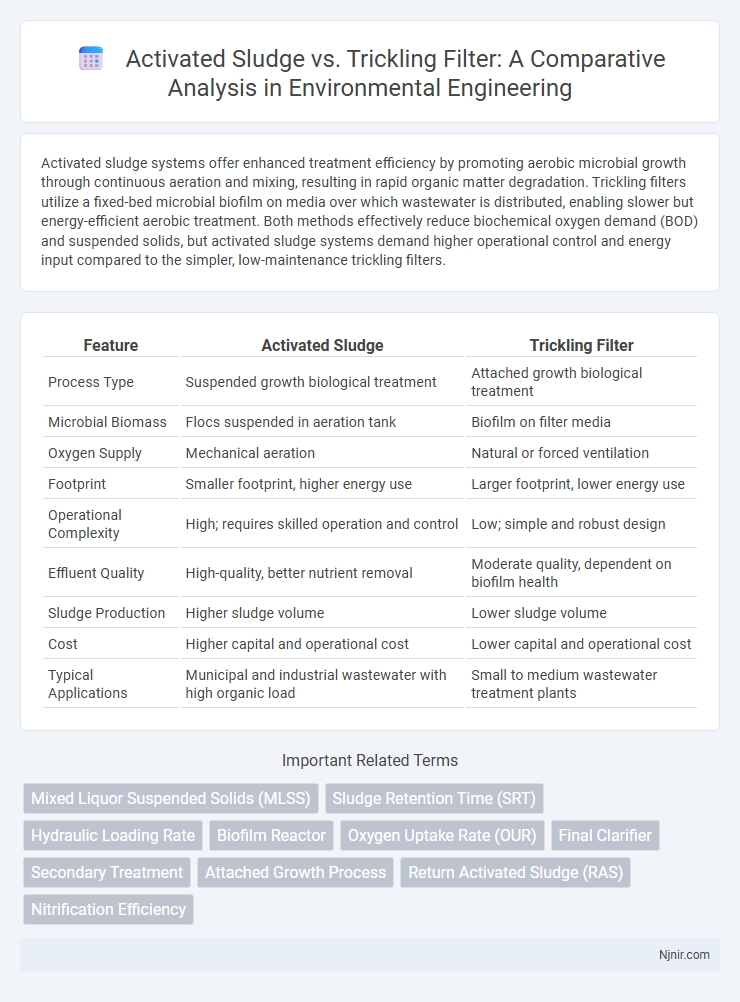

| Feature | Activated Sludge | Trickling Filter |

|---|---|---|

| Process Type | Suspended growth biological treatment | Attached growth biological treatment |

| Microbial Biomass | Flocs suspended in aeration tank | Biofilm on filter media |

| Oxygen Supply | Mechanical aeration | Natural or forced ventilation |

| Footprint | Smaller footprint, higher energy use | Larger footprint, lower energy use |

| Operational Complexity | High; requires skilled operation and control | Low; simple and robust design |

| Effluent Quality | High-quality, better nutrient removal | Moderate quality, dependent on biofilm health |

| Sludge Production | Higher sludge volume | Lower sludge volume |

| Cost | Higher capital and operational cost | Lower capital and operational cost |

| Typical Applications | Municipal and industrial wastewater with high organic load | Small to medium wastewater treatment plants |

Introduction to Biological Wastewater Treatment

Activated sludge and trickling filters are two primary methods in biological wastewater treatment that utilize microorganisms to degrade organic pollutants. Activated sludge systems rely on aerated tanks where a mixed microbial community breaks down waste, while trickling filters use a fixed bed of media coated with biofilm to treat the wastewater as it flows over the surface. Both processes are fundamental for reducing biological oxygen demand (BOD) and ensuring effective secondary treatment in municipal and industrial wastewater facilities.

Overview of Activated Sludge Process

The Activated Sludge process utilizes aerated tanks where microorganisms metabolize organic pollutants, transforming wastewater into clarified effluent and excess sludge. This biological treatment method offers rapid processing times and high efficiency in removing biochemical oxygen demand (BOD) and suspended solids. Unlike the Trickling Filter, this process allows better control over microbial growth and aeration, enhancing treatment performance for municipal and industrial wastewater.

Fundamentals of Trickling Filter Systems

Trickling filter systems treat wastewater by distributing it over a packed bed of media where microbial biofilms degrade organic matter through aerobic processes. They rely on fixed-film technology, which contrasts with the suspended growth approach of activated sludge systems, enabling lower energy consumption and simpler operational control. Understanding the fundamental mechanisms, such as media type, hydraulic loading rate, and microbial kinetics, is essential for optimizing trickling filter performance and achieving efficient organic pollutant removal.

Process Design and Operation Differences

Activated sludge systems utilize aerated tanks and microbial flocs for organic matter breakdown, requiring continuous air supply and mechanical mixing, whereas trickling filters rely on a fixed bed of media colonized by biofilm with wastewater distributed over the surface by gravity. The activated sludge process demands careful control of sludge age, aeration rate, and return activated sludge flow to maintain optimal microbial activity, while trickling filters operate with simpler aeration from ambient air and require periodic media cleaning to prevent clogging. Design considerations in activated sludge focus on tank volume, oxygen transfer efficiency, and sludge settling characteristics, contrasting with the trickling filter's emphasis on media type, depth, and hydraulic loading rate to ensure effective treatment.

Treatment Efficiency and Performance Comparison

Activated sludge systems offer higher treatment efficiency by promoting rapid microbial growth and superior organic matter removal, typically achieving BOD reductions of 85-95%. Trickling filters rely on a biofilm attached to media, resulting in slower reaction rates and slightly lower performance, often achieving BOD reductions around 70-85%. The activated sludge process generally provides better control over nutrient removal and sludge management, enhancing overall wastewater treatment performance.

Energy Consumption and Operational Costs

Activated sludge systems typically consume more energy due to intensive aeration requirements, resulting in higher operational costs compared to trickling filters. Trickling filters rely on passive airflow and biological media, which significantly reduces power consumption and maintenance expenses. Energy-efficient design and process optimization are critical for activated sludge to minimize overall operational costs relative to trickling filters.

Sludge Production and Handling

Activated sludge systems generate significantly more sludge compared to trickling filters due to higher biomass concentration and growth rates in the aeration tanks. The excess sludge from activated sludge processes requires regular removal, thickening, and stabilization, increasing handling complexity and costs. Trickling filters produce less sludge, mainly as biofilm slough, resulting in lower sludge handling demands and simplified disposal processes.

Suitability for Different Wastewater Types

Activated sludge systems excel in treating high-strength industrial and municipal wastewater due to their ability to handle variable loads and provide superior organic and nutrient removal. Trickling filters are more suitable for small to medium-sized communities with stable, low-strength domestic wastewater, offering lower operational costs and simpler maintenance. Both methods effectively reduce biochemical oxygen demand (BOD), but activated sludge is preferable for complex waste streams requiring advanced treatment.

Environmental Impact and Sustainability

Activated sludge systems offer higher organic load removal efficiency and produce less odor, minimizing environmental pollution compared to trickling filters. Trickling filters consume less energy due to the passive aeration process, contributing to lower carbon emissions and operational costs. Both systems support nutrient removal, but activated sludge provides greater control for reducing nitrogen and phosphorus discharges, enhancing aquatic ecosystem sustainability.

Selection Criteria and Practical Applications

Activated sludge systems offer superior treatment efficiency for high-strength wastewater and are favored in large municipal or industrial plants requiring rapid organic load reduction. Trickling filters provide robust performance with lower operational complexity and energy consumption, making them suitable for small to medium-sized communities with stable organic loads. Selection criteria prioritize influent characteristics, footprint availability, operational expertise, and budget constraints to optimize treatment outcomes.

Mixed Liquor Suspended Solids (MLSS)

Activated sludge systems maintain higher Mixed Liquor Suspended Solids (MLSS) concentrations, typically 2,000-4,000 mg/L, enhancing organic load processing compared to trickling filters, which rely more on biofilm with lower suspended solids levels.

Sludge Retention Time (SRT)

Activated sludge systems maintain a controlled sludge retention time (SRT) to optimize microbial growth and pollutant removal, whereas trickling filters have an inherently variable and generally shorter SRT due to biomass detachment.

Hydraulic Loading Rate

Hydraulic loading rate for activated sludge systems typically ranges from 0.5 to 1.5 m3/m2/day, whereas trickling filters handle higher rates between 2 to 10 m3/m2/day, reflecting their distinct design and treatment capacities.

Biofilm Reactor

Biofilm reactors, such as trickling filters, utilize a fixed microbial biofilm on media surfaces for efficient organic matter degradation, contrasting with activated sludge systems that rely on suspended microbial flocs in aeration tanks.

Oxygen Uptake Rate (OUR)

Activated sludge systems exhibit significantly higher Oxygen Uptake Rates (OUR) compared to trickling filters due to enhanced microbial activity and biomass concentration.

Final Clarifier

The final clarifier in activated sludge systems efficiently settles biomass flocs for sludge return and effluent extraction, whereas in trickling filter systems, it primarily separates filter media solids and microbial growth before discharge or further treatment.

Secondary Treatment

Activated sludge offers higher organic load removal efficiency and faster processing times compared to trickling filters in secondary wastewater treatment.

Attached Growth Process

The Attached Growth Process in trickling filters supports microorganisms growing on media surfaces to biologically treat wastewater, contrasting with the suspended biomass approach in activated sludge systems.

Return Activated Sludge (RAS)

Return Activated Sludge (RAS) in activated sludge systems recirculates settled biomass to maintain microbial concentration, enhancing organic pollutant degradation, whereas trickling filters do not utilize RAS, relying instead on biofilm growth on media for wastewater treatment.

Nitrification Efficiency

Activated sludge systems achieve higher nitrification efficiency, often exceeding 90%, by maintaining optimal oxygen levels and mixed microbial populations compared to trickling filters, which typically reach 60-80% nitrification efficiency due to biofilm limitations.

Activated Sludge vs Trickling Filter Infographic

njnir.com

njnir.com