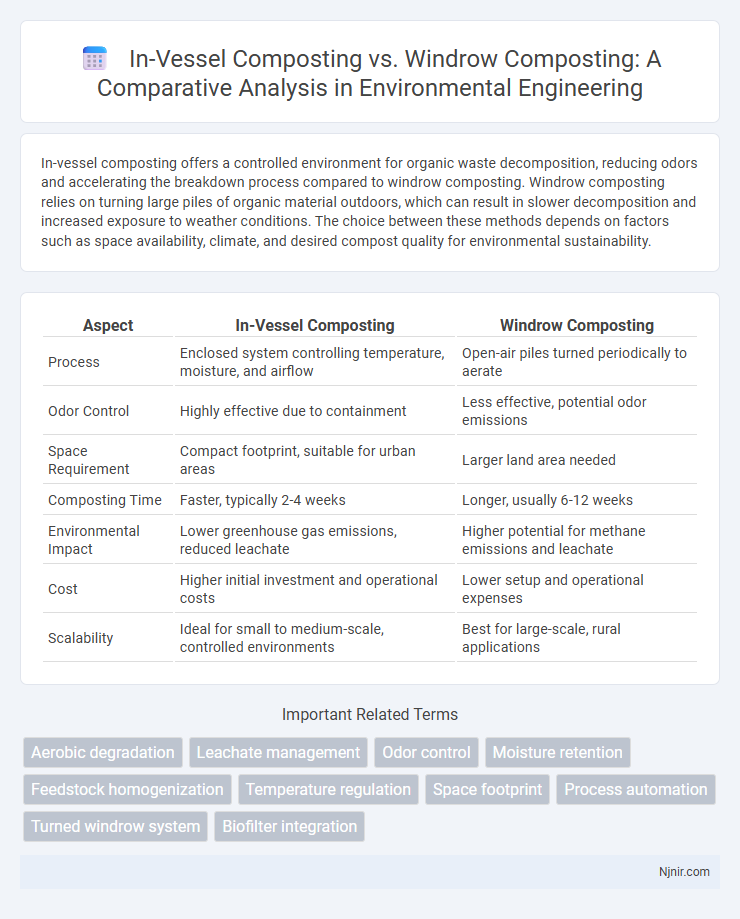

In-vessel composting offers a controlled environment for organic waste decomposition, reducing odors and accelerating the breakdown process compared to windrow composting. Windrow composting relies on turning large piles of organic material outdoors, which can result in slower decomposition and increased exposure to weather conditions. The choice between these methods depends on factors such as space availability, climate, and desired compost quality for environmental sustainability.

Table of Comparison

| Aspect | In-Vessel Composting | Windrow Composting |

|---|---|---|

| Process | Enclosed system controlling temperature, moisture, and airflow | Open-air piles turned periodically to aerate |

| Odor Control | Highly effective due to containment | Less effective, potential odor emissions |

| Space Requirement | Compact footprint, suitable for urban areas | Larger land area needed |

| Composting Time | Faster, typically 2-4 weeks | Longer, usually 6-12 weeks |

| Environmental Impact | Lower greenhouse gas emissions, reduced leachate | Higher potential for methane emissions and leachate |

| Cost | Higher initial investment and operational costs | Lower setup and operational expenses |

| Scalability | Ideal for small to medium-scale, controlled environments | Best for large-scale, rural applications |

Introduction to Composting Methods

In-vessel composting involves processing organic waste within enclosed containers, allowing for controlled temperature, moisture, and aeration to accelerate decomposition and reduce odors. Windrow composting requires forming large piles or rows of organic material exposed to the open air, relying on manual or mechanical turning to maintain aerobic conditions. In-vessel systems offer faster composting cycles and better environmental control, while windrow methods provide a cost-effective, scalable solution ideal for managing large volumes of organic waste in agricultural or municipal settings.

Overview of In-Vessel Composting

In-vessel composting confines organic waste within a controlled, enclosed environment, allowing precise regulation of temperature, moisture, and aeration to accelerate the decomposition process. This method significantly reduces odors, pathogens, and contaminants while producing high-quality compost in a shorter time compared to traditional open-air windrow composting. Facilities using in-vessel systems typically handle food waste, biosolids, and manure more efficiently, enabling year-round operation regardless of weather conditions.

Overview of Windrow Composting

Windrow composting involves piling organic waste into long rows, or windrows, which are regularly turned to maintain aerobic conditions and accelerate decomposition. This method is cost-effective and suitable for large-scale operations, particularly for yard waste, manure, and agricultural residues. Windrow composting requires sufficient space and careful management of moisture, temperature, and aeration to optimize microbial activity and produce high-quality compost.

Comparative Process Mechanisms

In-vessel composting confines organic waste in sealed, controlled environments, ensuring consistent temperature, aeration, and moisture levels to accelerate microbial decomposition. Windrow composting involves piling organic material in long rows exposed to natural conditions, relying on periodic turning to maintain aeration and temperature balance. The enclosed nature of in-vessel systems enables faster processing and better odor control compared to the open-air, slower, and more weather-dependent windrow method.

Space and Infrastructure Requirements

In-vessel composting requires significantly less space than windrow composting due to its enclosed, controlled environment, making it ideal for urban or space-limited settings. The infrastructure for in-vessel systems includes specialized containers, aeration systems, and temperature controls, increasing initial investment but enabling faster, odor-controlled composting. Windrow composting relies on large open areas for arranging organic material in long rows, demanding extensive land and minimal infrastructure beyond aeration tools and turning equipment.

Environmental Impact Assessment

In-vessel composting offers enhanced environmental control by containing odors, reducing greenhouse gas emissions, and preventing leachate compared to windrow composting, which exposes organic waste to open air and can lead to higher methane release and potential groundwater contamination. The closed system of in-vessel composting facilitates more efficient decomposition, minimizing air pollution and allowing better management of moisture and temperature, critical factors in environmental impact reduction. Windrow composting often requires more land space and intensive monitoring to mitigate environmental risks, whereas in-vessel systems provide a compact, manageable solution with a smaller ecological footprint.

Odor and Emission Control

In-vessel composting offers superior odor and emission control compared to windrow composting by containing the organic material within an enclosed system, which minimizes the release of volatile organic compounds (VOCs) and greenhouse gases such as methane and ammonia. Advanced aeration and biofiltration technologies integrated in in-vessel systems further reduce odor-causing compounds and particulate emissions. Windrow composting, being open to the atmosphere, often experiences greater odor dispersion and higher emissions due to less controlled airflow and environmental exposure.

Efficiency in Pathogen and Weed Seed Reduction

In-vessel composting achieves higher efficiency in pathogen and weed seed reduction due to its controlled environment, which maintains optimal temperature and moisture levels consistently. This method typically reaches thermophilic temperatures above 55degC (131degF) for extended periods, ensuring the complete inactivation of harmful microorganisms and resilient weed seeds. Windrow composting, while effective, often experiences variable temperature distribution and less consistent pathogen kill rates, making it less reliable for thorough sanitation compared to in-vessel systems.

Economic Considerations and Operating Costs

In-vessel composting typically requires higher initial capital investment and operational expenses due to advanced technology and controlled environment systems, but it offers faster processing times and reduced labor costs. Windrow composting has lower startup costs and simpler equipment needs, making it more accessible for large-scale, low-intensity operations, but it demands more land, manual handling, and longer composting cycles that can increase ongoing labor expenses. Overall, in-vessel composting provides higher efficiency and potential revenue generation through faster turnaround, while windrow methods benefit from lower overhead but increased variable operating costs.

Suitability for Different Waste Types

In-vessel composting is highly suitable for managing a variety of organic waste types, including food scraps, animal manure, and biosolids, due to its controlled environment that optimizes temperature, moisture, and aeration. Windrow composting is more effective for bulky, yard waste, wood chips, and agricultural residues, as it relies on natural aeration through turning large piles in open air. The enclosed design of in-vessel systems allows for faster decomposition and better odor control, making it ideal for food waste and urban organic materials, whereas windrow composting is cost-efficient for large-scale, less odor-sensitive biomass.

Aerobic degradation

In-vessel composting accelerates aerobic degradation by providing controlled temperature, moisture, and oxygen levels, while windrow composting relies on natural airflow and manual turning to maintain aerobic conditions.

Leachate management

In-vessel composting effectively controls leachate production by containing moisture within a closed system, whereas windrow composting relies on proper site drainage and frequent turning to minimize leachate runoff.

Odor control

In-vessel composting offers superior odor control compared to windrow composting due to its enclosed environment that contains and filters emissions effectively.

Moisture retention

In-vessel composting retains moisture more effectively than windrow composting due to its controlled environment that minimizes evaporation and allows precise humidity regulation.

Feedstock homogenization

In-vessel composting achieves superior feedstock homogenization through controlled environmental conditions and enclosed mixing mechanisms, unlike windrow composting which relies on external turning and exposure.

Temperature regulation

In-vessel composting provides precise temperature regulation through controlled enclosed environments, whereas windrow composting relies on ambient conditions and turning frequency for temperature management.

Space footprint

In-vessel composting requires significantly less space than windrow composting, making it ideal for urban environments and facilities with limited land availability.

Process automation

In-vessel composting offers enhanced process automation with controlled environments and real-time monitoring systems, whereas windrow composting relies more on manual labor and less precise process control.

Turned windrow system

Turned windrow composting accelerates organic waste decomposition by regularly aerating large, exposed piles, offering cost-effective scalability and lower infrastructure demands compared to the controlled environment and faster processing speeds of in-vessel composting systems.

Biofilter integration

In-vessel composting with integrated biofilters offers enhanced odor control and pathogen reduction compared to windrow composting, which typically relies on less efficient passive aeration and external biofilter setups.

in-vessel composting vs windrow composting Infographic

njnir.com

njnir.com