Geotextiles are permeable fabrics primarily used for filtration, separation, and drainage in soil stabilization projects, allowing water to pass while preventing soil erosion. Geogrids provide structural reinforcement by creating a grid-like pattern that distributes loads and enhances soil strength, making them ideal for retaining walls and embankments. While both materials improve soil performance, geotextiles focus on filtration and separation, whereas geogrids specialize in tensile reinforcement and load distribution.

Table of Comparison

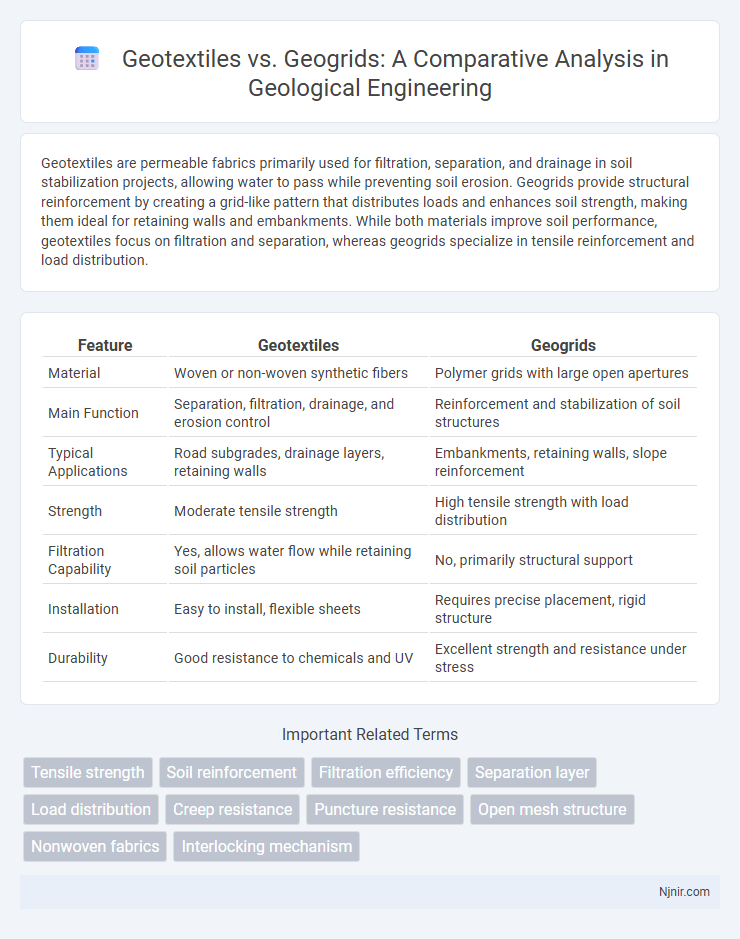

| Feature | Geotextiles | Geogrids |

|---|---|---|

| Material | Woven or non-woven synthetic fibers | Polymer grids with large open apertures |

| Main Function | Separation, filtration, drainage, and erosion control | Reinforcement and stabilization of soil structures |

| Typical Applications | Road subgrades, drainage layers, retaining walls | Embankments, retaining walls, slope reinforcement |

| Strength | Moderate tensile strength | High tensile strength with load distribution |

| Filtration Capability | Yes, allows water flow while retaining soil particles | No, primarily structural support |

| Installation | Easy to install, flexible sheets | Requires precise placement, rigid structure |

| Durability | Good resistance to chemicals and UV | Excellent strength and resistance under stress |

Introduction to Geotextiles and Geogrids

Geotextiles and geogrids are synthetic materials used in civil engineering to enhance soil stability and reinforcement. Geotextiles are permeable fabrics designed to separate, filter, reinforce, protect, or drain soil, commonly made from polypropylene or polyester. Geogrids, typically made from polymers like polyethylene or polypropylene, feature a grid-like structure that provides superior tensile strength and soil reinforcement in earthworks and retaining wall applications.

Material Composition and Manufacturing Differences

Geotextiles are typically made from woven or non-woven synthetic fibers like polypropylene or polyester, processed through needle punching, weaving, or heat bonding to create a permeable fabric. Geogrids consist of polymers such as high-density polyethylene (HDPE) or polypropylene, manufactured through extrusion and stretching to form a grid-like structure with open apertures for soil reinforcement. The key material composition difference lies in geotextiles' fibrous fabric form designed for filtration and separation, while geogrids are rigid, grid-patterned reinforcements engineered to provide tensile strength and soil stabilization.

Primary Functions in Geological Engineering

Geotextiles primarily serve as filtration, separation, and drainage materials by allowing water flow while preventing soil particle migration, which enhances soil stabilization in geological engineering projects. Geogrids provide tensile reinforcement to soils and aggregates, improving load distribution and controlling deformation, especially in retaining walls and embankments. The distinct functionalities of geotextiles and geogrids address specific mechanical and hydraulic requirements critical to soil reinforcement and erosion control.

Typical Applications in Civil and Geotechnical Projects

Geotextiles are primarily used for soil stabilization, filtration, separation, and drainage in civil and geotechnical projects, making them ideal for applications such as road construction, erosion control, and drainage systems. Geogrids provide reinforcement and load distribution by interlocking with soil or aggregate, commonly employed in retaining walls, embankments, and slope stabilization. Selecting between geotextiles and geogrids depends on project requirements like tensile strength, permeability, and soil compatibility.

Mechanical Properties: Strength and Durability

Geotextiles exhibit high tensile strength and excellent puncture resistance, making them suitable for soil stabilization and filtration applications. Geogrids offer superior tensile strength and stiffness due to their grid-like structure, providing enhanced load distribution and reinforcement capabilities in retaining walls and embankments. Both materials demonstrate exceptional durability against environmental degradation, with geogrids excelling in long-term mechanical performance under high stress conditions.

Installation Methods and Site Considerations

Geotextiles are typically installed by unrolling the fabric over prepared soil surfaces, ensuring overlap of seams by at least 30 cm to prevent gaps, and are secured using staples or pins to maintain position during construction. Geogrids require precise alignment and anchoring, often involving trenching or staking at edges to achieve optimal tension and interlock with aggregate materials, which enhances load distribution. Site considerations for geotextiles include soil type and drainage needs, while geogrids demand assessment of soil conditions, compaction quality, and load-bearing requirements to maximize reinforcement efficiency.

Cost Analysis: Geotextiles vs. Geogrids

Geotextiles typically present a lower initial cost compared to geogrids, making them a cost-effective solution for soil stabilization and erosion control in many projects. While geogrids often involve higher upfront expenses due to their complex manufacturing and installation processes, their superior tensile strength and long-term durability can lead to reduced maintenance and replacement costs. Evaluating the total lifecycle cost, including material, installation, and performance efficiency, is essential for accurate cost analysis between geotextiles and geogrids.

Performance in Soil Reinforcement

Geotextiles and geogrids both enhance soil reinforcement but differ in performance characteristics; geotextiles primarily provide filtration, separation, and drainage while allowing soil particles to pass through their woven or non-woven structure. Geogrids offer superior tensile strength and load distribution due to their grid-like structure, making them more effective for stabilizing slopes and supporting heavy loads in road construction. Performance efficiency depends on application specifics, soil type, and load requirements, with geogrids generally preferred for demanding reinforcement tasks and geotextiles suited for erosion control and drainage functions.

Environmental Impact and Sustainability

Geotextiles and geogrids play crucial roles in sustainable construction by reinforcing soil and preventing erosion, reducing the need for frequent repairs and resource use. Geotextiles, often made from polypropylene or polyester, are designed to filter and stabilize soil while allowing water flow, minimizing negative environmental impact through improved soil health and reduced sediment runoff. Geogrids, characterized by their grid structure, offer superior soil reinforcement with less material usage and longer lifespan, promoting sustainability by lowering carbon footprint and waste generation in infrastructure projects.

Selecting the Right Solution: Key Decision Factors

Selecting the right solution between geotextiles and geogrids depends on project-specific factors such as soil stabilization requirements, load-bearing capacity, and drainage needs. Geotextiles excel in separation, filtration, and erosion control due to their permeability and fine mesh structure, whereas geogrids provide superior reinforcement and tensile strength for soil and aggregate stabilization. Evaluating site conditions, mechanical properties, and environmental impact ensures optimal performance in civil engineering, road construction, and retaining wall applications.

Tensile strength

Geogrids generally offer higher tensile strength compared to geotextiles, making them more effective for soil reinforcement and load-bearing applications.

Soil reinforcement

Geotextiles enhance soil reinforcement by providing filtration and separation, while geogrids offer superior tensile strength and interlocking capabilities for stabilizing soil structures.

Filtration efficiency

Geotextiles provide superior filtration efficiency by allowing water flow while retaining soil particles, whereas geogrids primarily reinforce soil with limited filtration capabilities.

Separation layer

Geotextiles provide effective separation by preventing soil intermixing with aggregates, while geogrids primarily offer reinforcement but can also assist in separation when designed with appropriate apertures.

Load distribution

Geogrids provide superior load distribution in soil stabilization by creating a grid-like reinforcement structure that evenly spreads applied loads, whereas geotextiles primarily filter and separate without significantly enhancing load distribution.

Creep resistance

Geogrids demonstrate superior creep resistance compared to geotextiles, enhancing long-term stability in soil reinforcement applications.

Puncture resistance

Geogrids typically offer superior puncture resistance compared to geotextiles, making them more effective for soil stabilization in heavy load-bearing applications.

Open mesh structure

Geogrids feature an open mesh structure that provides superior soil reinforcement compared to the tighter weave of geotextiles, enhancing load distribution and stability in construction projects.

Nonwoven fabrics

Nonwoven geotextiles provide superior filtration and drainage compared to geogrids, which primarily offer tensile reinforcement in soil stabilization applications.

Interlocking mechanism

Geogrids feature a rigid, grid-like structure that provides superior soil particle interlocking compared to the flexible, woven or non-woven fibers of geotextiles, enhancing load distribution and stabilization in civil engineering applications.

Geotextiles vs Geogrids Infographic

njnir.com

njnir.com