Laterite and bauxite are both significant ores in geological engineering, primarily used for aluminum extraction; laterite forms through intense weathering of silicate rocks in tropical climates, resulting in iron and aluminum-rich soil, whereas bauxite is a sedimentary rock composed mainly of hydrated aluminum oxides. The geotechnical properties of laterite include high porosity and clay content, making it suitable for road construction and foundation fills, in contrast to bauxite, which is harder and more resistant due to its dense mineral composition. Understanding the mineralogy and mechanical behavior of these materials is crucial for sustainable mining and efficient resource management in engineering projects.

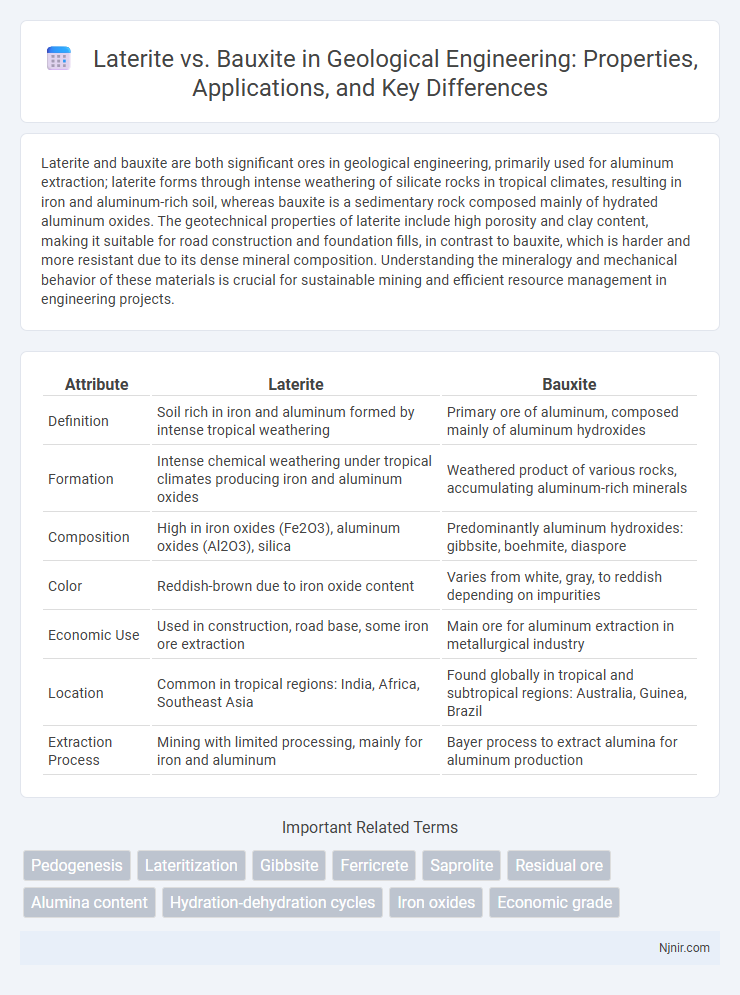

Table of Comparison

| Attribute | Laterite | Bauxite |

|---|---|---|

| Definition | Soil rich in iron and aluminum formed by intense tropical weathering | Primary ore of aluminum, composed mainly of aluminum hydroxides |

| Formation | Intense chemical weathering under tropical climates producing iron and aluminum oxides | Weathered product of various rocks, accumulating aluminum-rich minerals |

| Composition | High in iron oxides (Fe2O3), aluminum oxides (Al2O3), silica | Predominantly aluminum hydroxides: gibbsite, boehmite, diaspore |

| Color | Reddish-brown due to iron oxide content | Varies from white, gray, to reddish depending on impurities |

| Economic Use | Used in construction, road base, some iron ore extraction | Main ore for aluminum extraction in metallurgical industry |

| Location | Common in tropical regions: India, Africa, Southeast Asia | Found globally in tropical and subtropical regions: Australia, Guinea, Brazil |

| Extraction Process | Mining with limited processing, mainly for iron and aluminum | Bayer process to extract alumina for aluminum production |

Introduction to Laterite and Bauxite

Laterite and bauxite are distinct types of soil and ore rich in aluminum minerals, found predominantly in tropical regions. Laterite forms from prolonged weathering of silicate rocks, typically rich in iron and aluminum oxides, while bauxite is the primary ore of aluminum, composed mostly of gibbsite, boehmite, and diaspore minerals. Both materials are vital for their respective uses in construction, soil conditioning, and aluminum production, with laterite serving as a base for road construction and bauxite being the essential raw material for aluminum extraction.

Geological Formation Processes

Laterite forms through intense tropical weathering of silicate rocks, resulting in the leaching of silica and enrichment of iron and aluminum oxides. Bauxite develops in similar tropical conditions but primarily accumulates through the weathering of aluminum-rich rocks combined with the removal of soluble materials. Both processes involve prolonged chemical weathering, but the mineralogy and geochemical environment distinguish laterite's iron-rich profile from bauxite's aluminum ore characteristics.

Mineralogical Composition Differences

Laterite primarily consists of iron and aluminum oxides, such as hematite and goethite, alongside silica and kaolinite, reflecting intense weathering processes in tropical climates. Bauxite is rich in aluminum minerals like gibbsite, boehmite, and diaspore, which constitute the main ore minerals targeted for aluminum extraction. The key mineralogical difference lies in bauxite's dominance of aluminum hydroxides, whereas laterite contains a broader mix of oxides with lower aluminum concentration.

Physical and Chemical Properties

Laterite exhibits a reddish-brown color due to high iron oxide content, with a porous and rough texture, strong in aluminum and iron oxides but low in silica. Bauxite, primarily composed of hydrous aluminum oxides like gibbsite, boehmite, and diaspore, has a softer, earthy texture with variable color ranging from white to reddish-brown, and contains impurities such as silica, iron oxides, and titanium dioxide. Chemically, laterite is rich in ferric oxide (Fe2O3) and aluminum oxide (Al2O3) with significant silica (SiO2) content, whereas bauxite has high alumina (Al2O3) concentration with minimal silica, making it the principal ore for aluminum extraction.

Global Distribution and Occurrence

Laterite primarily forms in tropical regions with intense weathering, prominently found in countries such as India, Indonesia, and Brazil, where climate conditions favor the leaching of silicates. Bauxite deposits, the main ore of aluminum, are globally distributed but concentrated in Australia, Guinea, and Jamaica, regions characterized by a tropical to subtropical climate that supports aluminum-rich soil formation. Both laterite and bauxite occur as residual deposits near the surface, but bauxite often accumulates in lowland areas while laterite surfaces more broadly across plateaus and uplands.

Methods of Exploration and Extraction

Laterite exploration involves geological mapping, geochemical sampling, and geophysical surveys to identify iron and aluminum-rich zones, often followed by trenching and drilling to assess ore thickness and grade. Extraction methods for laterite primarily include open-pit mining combined with hydraulic mining or dredging to separate iron ore or aluminum-bearing minerals, followed by beneficiation techniques like magnetic separation and acid leaching. Bauxite exploration relies on surface mapping, aerial surveys, and sampling to locate aluminum-rich lateritic soils, with drilling used to evaluate deposits, while extraction employs open-pit mining and dry or wet beneficiation processes such as washing, screening, and jigging to obtain high-grade aluminum ore.

Industrial Applications and Uses

Laterite is predominantly used in construction, road building, and as a raw material for iron extraction due to its high iron oxide content. Bauxite serves as the primary ore for aluminum production, essential in aerospace, automotive, and packaging industries. Both minerals support industrial applications but differ in their primary metal outputs--iron from laterite and aluminum from bauxite.

Environmental Impact and Sustainability

Laterite mining often causes significant soil erosion and deforestation, leading to habitat loss and reduced biodiversity, while bauxite extraction also results in land degradation but typically includes rehabilitation measures such as land restoration and reforestation. Bauxite refining produces red mud, a toxic by-product posing disposal challenges, whereas laterite processing generally has a lower chemical waste footprint. Sustainable practices in bauxite mining, including residue management and water treatment, are more developed compared to those in laterite extraction, influencing their respective environmental impacts and long-term ecological sustainability.

Economic Significance and Market Trends

Laterite is a crucial source of iron and aluminum ores, particularly in tropical regions, driving local economies through mining activities and export revenue. Bauxite, the primary ore for aluminum production, holds immense economic significance worldwide, with a robust market driven by demand in aerospace, automotive, and packaging industries. Market trends indicate increasing investments in sustainable extraction technologies for both laterite and bauxite, responding to environmental regulations and the growing need for lightweight, durable materials.

Future Prospects in Geological Engineering

Laterite and bauxite deposits hold critical importance for future geological engineering projects due to their extensive use in aluminum production and soil stabilization techniques. Advances in exploration technologies and sustainable mining practices will enhance resource efficiency and minimize environmental impact, driving innovations in extraction and processing methods. Emerging trends emphasize the potential of laterite for nickel extraction and bauxite for developing lightweight construction materials, promising significant contributions to sustainable development and industrial growth.

Pedogenesis

Laterite forms through intense tropical weathering and leaching during pedogenesis, resulting in iron and aluminum-rich soils, whereas bauxite develops as a residual ore primarily from the further concentration of aluminum oxides under prolonged pedogenetic processes.

Lateritization

Lateritization transforms silicate rocks into laterite rich in iron and aluminum oxides, whereas bauxite forms primarily through intense weathering and leaching of aluminum-rich rocks, making lateritization the critical process differentiating laterite from bauxite.

Gibbsite

Gibbsite, a primary aluminum ore mineral found predominantly in bauxite, distinguishes bauxite from laterite by its high aluminum hydroxide content essential for aluminum production.

Ferricrete

Ferricrete, a hardened layer found in laterite soils, differs from bauxite deposits primarily in its high iron oxide content and cemented texture, impacting its use and formation processes in tropical and subtropical regions.

Saprolite

Saprolite in laterite forms a weathered, clay-rich layer beneath the ferruginous zone, while in bauxite deposits, saprolite serves as the aluminum-rich substrate from which economically valuable bauxite ores are extracted.

Residual ore

Laterite is a weathered residual ore rich in iron and aluminum oxides formed by intense tropical weathering, while bauxite is a specific type of residual ore composed primarily of hydrated aluminum oxides, serving as the principal aluminum ore.

Alumina content

Bauxite contains a higher alumina content, typically 40-60%, compared to laterite, which generally has lower alumina levels around 10-20%.

Hydration-dehydration cycles

Laterite forms through intensive hydration-dehydration cycles that leach silica and concentrate iron and aluminum oxides, while bauxite primarily results from prolonged weathering with minimal hydration-dehydration fluctuations, leading to high aluminum hydroxide content.

Iron oxides

Laterite contains a higher concentration of iron oxides compared to bauxite, which primarily consists of aluminum oxides.

Economic grade

Laterite contains lower economic-grade aluminum ore compared to high-grade bauxite, which is the primary source for commercial aluminum extraction.

Laterite vs Bauxite Infographic

njnir.com

njnir.com