Remote inspections in marine engineering leverage advanced technologies such as drones, ROVs, and high-resolution cameras to assess vessel conditions without the need for physical presence, enhancing safety and reducing downtime. Onsite inspections provide direct, hands-on evaluation, allowing engineers to perform detailed assessments and immediate repairs, but they can be time-consuming and pose safety risks in hazardous environments. Balancing remote and onsite inspections optimizes maintenance strategies by combining the efficiency of remote data collection with the thoroughness of direct human expertise.

Table of Comparison

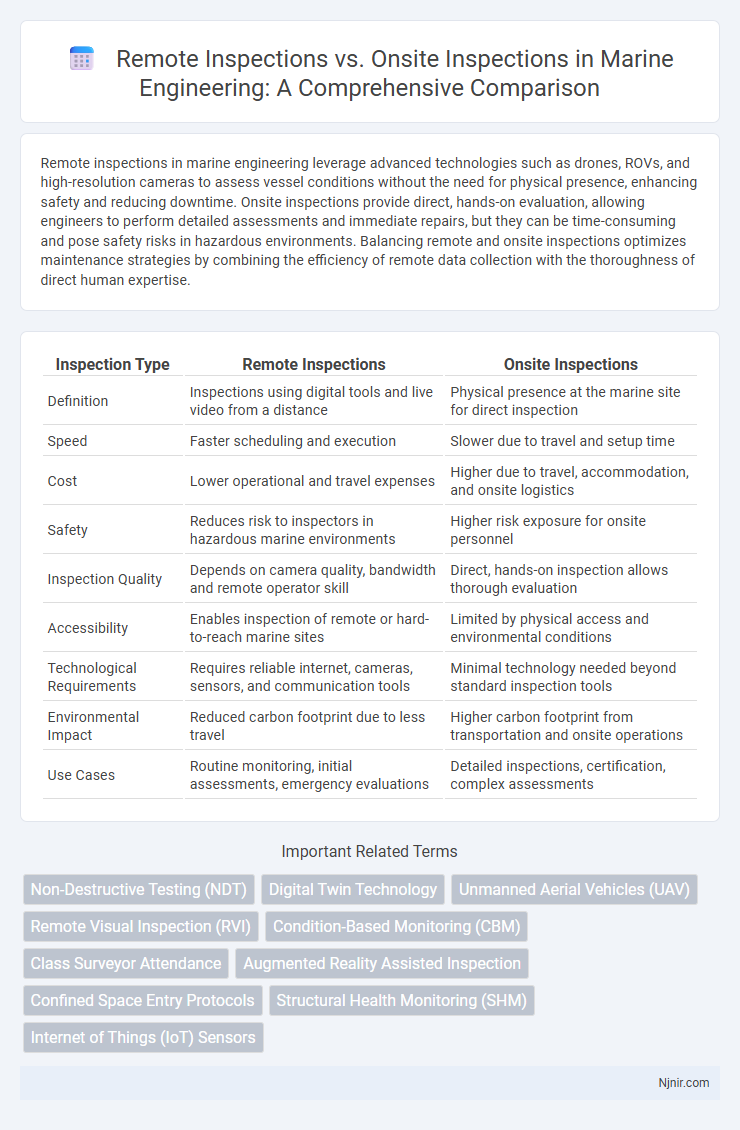

| Inspection Type | Remote Inspections | Onsite Inspections |

|---|---|---|

| Definition | Inspections using digital tools and live video from a distance | Physical presence at the marine site for direct inspection |

| Speed | Faster scheduling and execution | Slower due to travel and setup time |

| Cost | Lower operational and travel expenses | Higher due to travel, accommodation, and onsite logistics |

| Safety | Reduces risk to inspectors in hazardous marine environments | Higher risk exposure for onsite personnel |

| Inspection Quality | Depends on camera quality, bandwidth and remote operator skill | Direct, hands-on inspection allows thorough evaluation |

| Accessibility | Enables inspection of remote or hard-to-reach marine sites | Limited by physical access and environmental conditions |

| Technological Requirements | Requires reliable internet, cameras, sensors, and communication tools | Minimal technology needed beyond standard inspection tools |

| Environmental Impact | Reduced carbon footprint due to less travel | Higher carbon footprint from transportation and onsite operations |

| Use Cases | Routine monitoring, initial assessments, emergency evaluations | Detailed inspections, certification, complex assessments |

Introduction to Inspections in Marine Engineering

Remote inspections leverage advanced technologies such as drones, sensors, and video conferencing to conduct thorough assessments of marine vessels and equipment without physical presence, significantly reducing downtime and costs. Onsite inspections involve direct physical examination by marine engineers, enabling hands-on evaluation of structural integrity, machinery, and safety compliance essential for detailed diagnostics. Both inspection methods play critical roles in ensuring operational efficiency and regulatory adherence in marine engineering.

Understanding Remote Inspections

Remote inspections utilize digital tools such as high-resolution cameras, drones, and real-time video streaming to assess sites without physical presence, enhancing efficiency and reducing travel costs. Advanced software with artificial intelligence enables detailed analysis and annotation during remote inspections, improving accuracy and documentation. Understanding remote inspections involves recognizing their capability to provide timely, comprehensive evaluations while ensuring safety and compliance in environments difficult to access onsite.

Overview of Onsite Inspections

Onsite inspections involve physical presence at the location to assess conditions, equipment, or processes directly, ensuring comprehensive evaluation through hands-on observation. This method allows inspectors to verify compliance with safety regulations, environmental standards, and quality controls in real-time. Onsite inspections are essential in industries such as construction, manufacturing, and oil and gas, where precise, immediate data collection and contextual understanding are critical.

Key Technologies Enabling Remote Inspections

Remote inspections leverage advanced technologies such as high-resolution video streaming, augmented reality (AR), and Internet of Things (IoT) sensors to enable real-time data collection and analysis without physical presence. Digital platforms powered by artificial intelligence (AI) facilitate defect detection and predictive maintenance, enhancing accuracy and efficiency. These technologies reduce downtime and travel costs while ensuring compliance with safety and quality standards traditionally upheld in onsite inspections.

Cost Efficiency: Remote vs Onsite Inspections

Remote inspections reduce travel and labor expenses by leveraging digital tools, resulting in significant cost savings compared to onsite inspections. Onsite inspections incur higher costs due to transportation, accommodation, and time spent at the location, impacting overall project budgets. Utilizing remote inspection technologies optimizes resource allocation and enhances cost efficiency in various industries.

Accuracy and Reliability Comparison

Remote inspections leverage high-resolution imaging and real-time data transmission to achieve accuracy comparable to onsite inspections, especially in environments where physical access is limited. Advanced sensors and AI-powered analytics enhance the reliability of remote assessments by identifying defects and anomalies with minimal human error. However, onsite inspections provide direct tactile evaluation and immediate validation, making them indispensable for complex scenarios requiring precise judgment and hands-on testing.

Safety Considerations for Marine Inspections

Remote inspections in marine settings significantly reduce exposure to hazardous environments, minimizing the risk of accidents and injuries associated with onboard conditions such as heavy machinery and unstable surfaces. Onsite inspections, while allowing direct evaluation for safety compliance of equipment and structural integrity, pose greater risks due to factors like confined spaces, weather conditions, and potential chemical exposure. Prioritizing remote inspection technologies, including drones and digital imaging, enhances safety protocols by limiting personnel presence in dangerous maritime zones.

Environmental Impact Assessment

Remote inspections in Environmental Impact Assessment (EIA) minimize carbon emissions by reducing the need for travel and the associated fuel consumption, unlike traditional onsite inspections that require transportation to often remote locations. Advanced technologies such as drones, satellite imagery, and remote sensing enable comprehensive data collection and monitoring without disturbing natural habitats. This approach not only lowers the environmental footprint but also accelerates data analysis and improves the frequency and coverage of environmental monitoring.

Regulatory Compliance and Challenges

Remote inspections enable regulatory compliance by utilizing digital tools to collect, analyze, and store data efficiently, reducing the risk of human error and ensuring real-time monitoring adherence to standards. Onsite inspections offer direct physical verification of conditions, crucial for detecting non-compliance that digital methods might overlook, but they entail higher costs, logistical challenges, and limited scalability. The primary challenge in remote inspections is ensuring data integrity and cybersecurity, while onsite inspections face limitations due to geographic constraints and time consumption.

Future Trends in Marine Inspection Methods

Future trends in marine inspection methods emphasize the integration of remote inspection technologies such as drones, ROVs, and AI-powered analysis tools, enhancing accuracy and safety while reducing operational costs. Onsite inspections remain crucial for complex assessments, but hybrid approaches combining remote data collection with targeted physical checks are gaining traction to optimize efficiency. Advancements in sensor technology and real-time data transmission are driving a shift towards predictive maintenance and continuous monitoring in marine inspections.

Non-Destructive Testing (NDT)

Remote inspections in Non-Destructive Testing (NDT) leverage advanced sensors and real-time data transmission to enhance efficiency, safety, and accessibility compared to traditional onsite inspections requiring physical presence and direct interaction with materials.

Digital Twin Technology

Digital Twin Technology enhances remote inspections by providing real-time, accurate virtual replicas of physical assets, significantly improving efficiency and reducing the need for costly onsite inspections.

Unmanned Aerial Vehicles (UAV)

Unmanned Aerial Vehicles (UAVs) enable remote inspections by providing high-resolution aerial data, reducing the need for risky onsite inspections and enhancing efficiency in infrastructure monitoring.

Remote Visual Inspection (RVI)

Remote Visual Inspection (RVI) enhances efficiency and safety by using high-resolution cameras and drones to detect defects in hard-to-reach areas, reducing the need for time-consuming and costly onsite inspections.

Condition-Based Monitoring (CBM)

Condition-Based Monitoring (CBM) enhances Remote inspections by providing real-time data and predictive analytics that improve accuracy and reduce costs compared to traditional Onsite inspections.

Class Surveyor Attendance

Remote inspections minimize Class Surveyor attendance by enabling real-time digital assessments, whereas onsite inspections require physical presence for thorough vessel evaluations.

Augmented Reality Assisted Inspection

Augmented Reality Assisted Inspection enhances remote inspections by overlaying real-time data and 3D models onto physical equipment, improving accuracy and reducing the need for onsite visits.

Confined Space Entry Protocols

Remote inspections for confined space entry protocols enhance safety and efficiency by minimizing direct exposure to hazardous environments compared to traditional onsite inspections.

Structural Health Monitoring (SHM)

Remote inspections using Structural Health Monitoring (SHM) offer continuous, real-time data acquisition and analysis, enhancing early detection of structural issues compared to periodic onsite inspections.

Internet of Things (IoT) Sensors

Remote inspections leveraging Internet of Things (IoT) sensors enable real-time data collection and analysis, significantly enhancing efficiency and accuracy compared to traditional onsite inspections.

Remote inspections vs Onsite inspections Infographic

njnir.com

njnir.com