Cold ironing involves connecting a docked ship to shore-based electrical power, allowing the vessel to shut down its engines and reduce emissions significantly. Hot stacking refers to keeping the ship's engines running at low loads while docked, which prevents engine wear but continues to produce environmental pollutants. Implementing cold ironing improves air quality in port areas and supports regulatory compliance, while hot stacking balances engine maintenance priorities with operational demands.

Table of Comparison

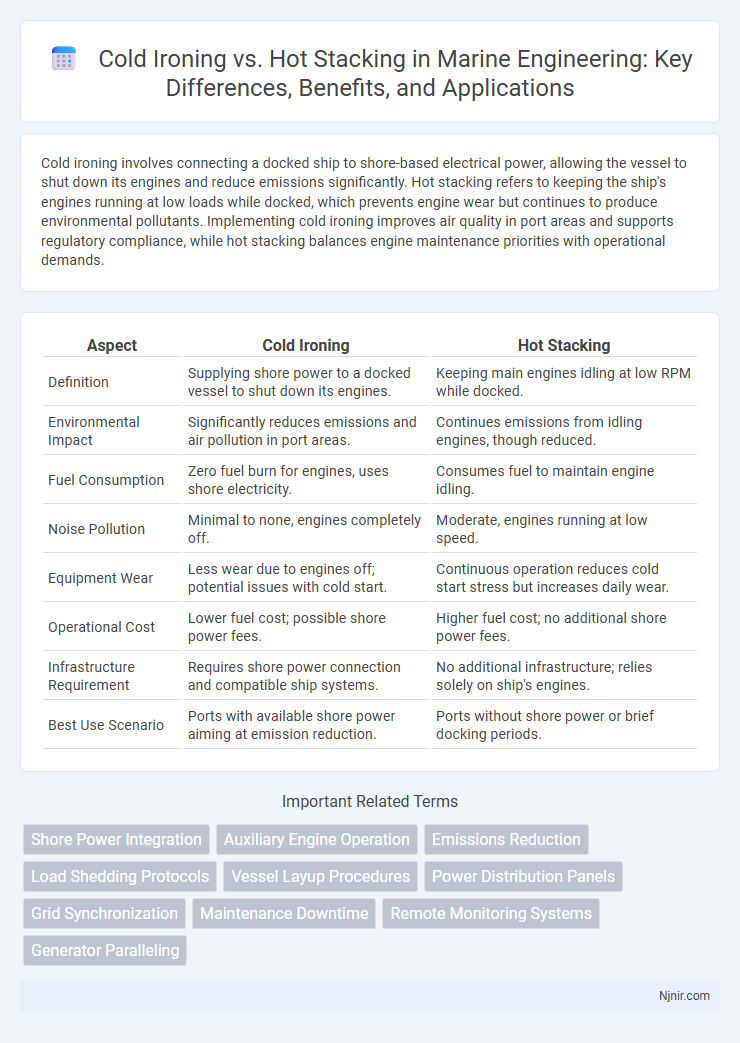

| Aspect | Cold Ironing | Hot Stacking |

|---|---|---|

| Definition | Supplying shore power to a docked vessel to shut down its engines. | Keeping main engines idling at low RPM while docked. |

| Environmental Impact | Significantly reduces emissions and air pollution in port areas. | Continues emissions from idling engines, though reduced. |

| Fuel Consumption | Zero fuel burn for engines, uses shore electricity. | Consumes fuel to maintain engine idling. |

| Noise Pollution | Minimal to none, engines completely off. | Moderate, engines running at low speed. |

| Equipment Wear | Less wear due to engines off; potential issues with cold start. | Continuous operation reduces cold start stress but increases daily wear. |

| Operational Cost | Lower fuel cost; possible shore power fees. | Higher fuel cost; no additional shore power fees. |

| Infrastructure Requirement | Requires shore power connection and compatible ship systems. | No additional infrastructure; relies solely on ship's engines. |

| Best Use Scenario | Ports with available shore power aiming at emission reduction. | Ports without shore power or brief docking periods. |

Introduction to Cold Ironing and Hot Stacking

Cold ironing, also known as shore power, involves supplying a vessel with electrical power from the shore while docked, enabling the ship to shut down its auxiliary engines and reduce emissions significantly. Hot stacking refers to maintaining a ship's engines in a warmed-up state without full operation, allowing for quicker startup but continuing to consume fuel and produce emissions. Both methods aim to balance energy efficiency and environmental impact during vessel downtime at port.

Key Differences Between Cold Ironing and Hot Stacking

Cold ironing involves shutting down a ship's engines and connecting to shore power to reduce emissions and noise while docked, whereas hot stacking keeps engines running at low power to prevent wear and maintain readiness. Cold ironing significantly reduces fuel consumption and pollutant emissions, enhancing environmental compliance, while hot stacking allows immediate engine availability but emits more pollutants. The key difference lies in environmental impact and engine operational state: cold ironing promotes sustainability by using external power, while hot stacking prioritizes operational efficiency at the cost of higher emissions.

Environmental Impacts of Cold Ironing

Cold ironing significantly reduces air pollution and greenhouse gas emissions by allowing ships to shut down their auxiliary engines and plug into shore power, eliminating harmful exhaust gases such as NOx, SOx, and particulate matter. By using clean electricity from the grid instead of burning heavy fuel oil or marine diesel, cold ironing decreases carbon dioxide emissions, contributing to improved air quality in port areas and mitigating climate change. This method supports sustainable maritime operations and complies with stricter environmental regulations imposed by organizations like the IMO and local authorities.

Environmental Impacts of Hot Stacking

Hot stacking significantly increases pollutant emissions due to continuous engine idling, resulting in elevated levels of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter released into the atmosphere. This practice contributes to higher greenhouse gas emissions, exacerbating air quality degradation and climate change risks in port areas. In contrast, reducing hot stacking emissions through cold ironing minimizes environmental harm by utilizing shore power, which lowers carbon footprints and supports sustainable maritime operations.

Operational Procedures for Cold Ironing

Cold ironing involves connecting a docked ship to shore-based electrical power, allowing onboard engines to be shut down during port stays and significantly reducing fuel consumption and emissions. Operational procedures for cold ironing require precise synchronization of power supply voltages and frequencies between the shore facility and the vessel, along with rigorous safety protocols to manage electrical hazards and ensure seamless power transfer. Continuous monitoring of electrical loads and coordination between the ship's engineering team and the port power provider are essential to maintain stable operations and prevent power disruptions.

Operational Procedures for Hot Stacking

Hot stacking involves keeping ship engines running at a low RPM during idle periods, reducing startup time and minimizing thermal stress on engine components. Operational procedures for hot stacking require careful monitoring of engine temperature, fuel consumption, and emissions to maintain engine efficiency while preventing wear. Crew members follow strict protocols for throttle management and engine condition checks to ensure safe and compliant hot stacking operations.

Economic Considerations: Cost Comparison

Cold ironing reduces fuel consumption and emissions by using shore power, resulting in lower operational costs compared to hot stacking, which keeps engines idling and consumes fuel continuously. Hot stacking incurs higher expenses due to fuel use, increased maintenance from engine wear, and environmental penalties, making it less cost-effective over extended periods. Investing in cold ironing infrastructure offers long-term economic benefits by minimizing fuel costs and complying with stricter emission regulations.

Regulatory Compliance and Industry Standards

Cold ironing, also known as shore power, requires vessels to comply with strict emission reduction regulations such as the IMO's MARPOL Annex VI and local port authority standards, significantly lowering air pollution by connecting ships to onshore electrical power sources. Hot stacking, the practice of idling ship engines while docked, faces increasing regulatory restrictions due to continued exhaust emissions that violate environmental compliance and air quality standards established by agencies like the EPA and the European Union. Industry standards prioritize cold ironing as the preferred method for reducing greenhouse gases and meeting sustainability goals, reflecting a global shift towards cleaner maritime operations.

Technological Advancements in Marine Power Solutions

Cold Ironing and Hot Stacking represent critical marine power solutions optimized through advanced technologies such as automated shore power systems and energy-efficient engine management software. Innovations in smart grid integration and real-time monitoring enable vessels to minimize emissions and fuel consumption during port stays, enhancing environmental compliance. Enhanced sensors and predictive analytics further improve engine durability and reduce operational costs by optimizing power transitions between docked and underway modes.

Future Perspectives on Sustainable Vessel Management

Cold ironing enables vessels to connect to shore power, significantly reducing emissions during port calls and aligning with global sustainability targets for maritime operations. Hot stacking optimizes fleet utilization by temporarily deactivating engines during idle periods, minimizing fuel consumption and operational costs while supporting cleaner shipping practices. Integrating both strategies offers a comprehensive approach to sustainable vessel management, promoting carbon footprint reduction and compliance with evolving environmental regulations.

Shore Power Integration

Cold ironing enables ships to connect to shore power grids for emissions-free energy supply during port stays, while hot stacking prolongs engine idling to maintain equipment readiness but results in higher fuel consumption and emissions without shore power integration.

Auxiliary Engine Operation

Cold ironing eliminates auxiliary engine operation by connecting ships to shore power, while hot stacking keeps auxiliary engines running at low load during harbor stays to maintain readiness.

Emissions Reduction

Cold ironing significantly reduces maritime emissions by allowing ships to shut down engines and connect to onshore power, whereas hot stacking maintains engines idling, resulting in higher pollutant output.

Load Shedding Protocols

Cold ironing minimizes emissions by supplying shore power during vessel load shedding protocols, whereas hot stacking maintains engine operation but demands complex load management to prevent power interruptions.

Vessel Layup Procedures

Cold ironing involves connecting vessels to shore power to minimize emissions during layup, while hot stacking maintains engines operational at low loads to keep systems warm and prevent corrosion in vessel layup procedures.

Power Distribution Panels

Cold ironing uses shore power to supply vessel power through specialized power distribution panels, reducing emissions, while hot stacking maintains engine operation with onboard power distribution panels to optimize fuel efficiency and system readiness.

Grid Synchronization

Cold ironing ensures stable grid synchronization by using shore power to match vessel frequency, whereas hot stacking maintains onboard generators synchronized with the grid to support load transitions seamlessly.

Maintenance Downtime

Cold ironing reduces maintenance downtime by allowing ships to power down engines while docked, whereas hot stacking increases downtime risk due to constant engine operation and associated wear.

Remote Monitoring Systems

Remote monitoring systems enhance cold ironing by providing real-time energy usage data and system status, enabling efficient shore power management, while hot stacking benefits from continuous engine performance monitoring to optimize fuel consumption and reduce emissions during low-load operations.

Generator Paralleling

Cold ironing eliminates emissions by connecting ship power to shore electricity, while hot stacking manages generator paralleling by maintaining running generators at low load to optimize efficiency and minimize wear.

Cold Ironing vs Hot Stacking Infographic

njnir.com

njnir.com