Azimuth thrusters provide superior maneuverability by allowing 360-degree rotation, making them ideal for vessels requiring precise steering and dynamic positioning. Tunnel thrusters, installed transversely in a ship's hull, enhance low-speed maneuvering primarily during docking but lack the full rotational capability of azimuth thrusters. Efficiency and operational scenarios differ significantly, with azimuth thrusters offering better performance in open waters and tunnel thrusters supporting fine adjustments in confined spaces.

Table of Comparison

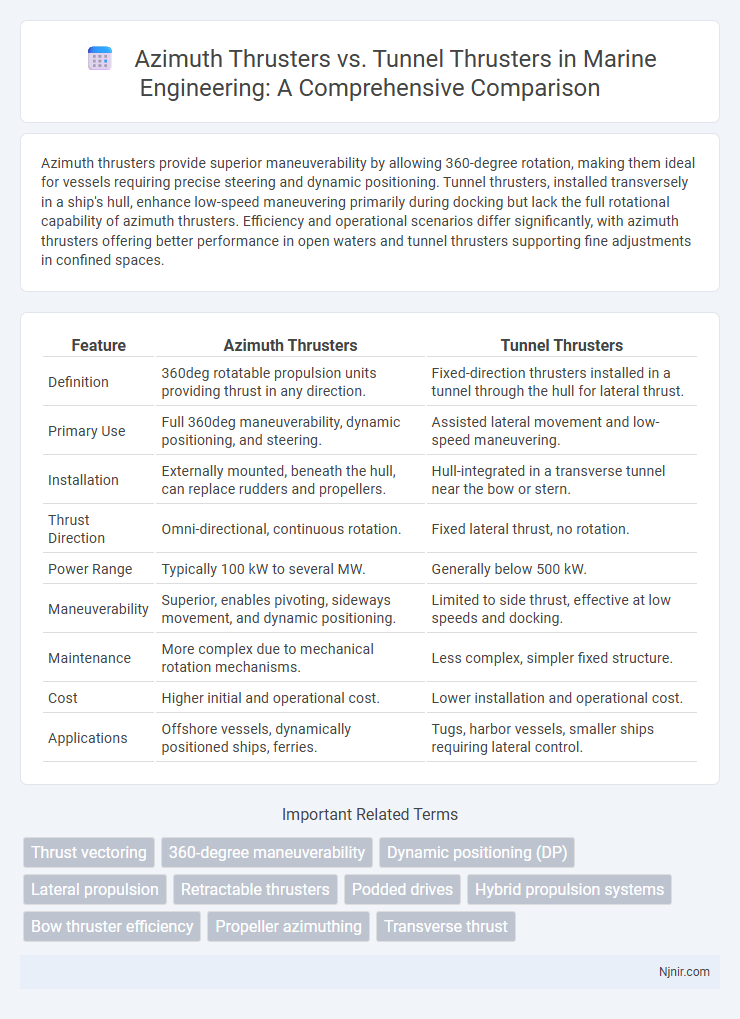

| Feature | Azimuth Thrusters | Tunnel Thrusters |

|---|---|---|

| Definition | 360deg rotatable propulsion units providing thrust in any direction. | Fixed-direction thrusters installed in a tunnel through the hull for lateral thrust. |

| Primary Use | Full 360deg maneuverability, dynamic positioning, and steering. | Assisted lateral movement and low-speed maneuvering. |

| Installation | Externally mounted, beneath the hull, can replace rudders and propellers. | Hull-integrated in a transverse tunnel near the bow or stern. |

| Thrust Direction | Omni-directional, continuous rotation. | Fixed lateral thrust, no rotation. |

| Power Range | Typically 100 kW to several MW. | Generally below 500 kW. |

| Maneuverability | Superior, enables pivoting, sideways movement, and dynamic positioning. | Limited to side thrust, effective at low speeds and docking. |

| Maintenance | More complex due to mechanical rotation mechanisms. | Less complex, simpler fixed structure. |

| Cost | Higher initial and operational cost. | Lower installation and operational cost. |

| Applications | Offshore vessels, dynamically positioned ships, ferries. | Tugs, harbor vessels, smaller ships requiring lateral control. |

Introduction to Marine Propulsion Systems

Azimuth thrusters provide 360-degree rotation, offering superior maneuverability and efficiency in marine propulsion systems compared to fixed tunnel thrusters, which are typically limited to lateral movement. Azimuth thrusters integrate propulsion and steering functions, enabling precise vessel control and reducing the need for rudders. Tunnel thrusters, installed in bow or stern tunnels, primarily aid in low-speed docking and station-keeping by generating sideways thrust but lack the versatility of azimuth thrusters in dynamic marine environments.

Overview of Azimuth Thrusters

Azimuth thrusters provide 360-degree rotation, enabling precise maneuverability and propulsion control for vessels of various sizes. These units integrate the propeller and steering functions, eliminating the need for a traditional rudder and enhancing operational efficiency. Commonly used in tugboats, offshore supply vessels, and dynamic positioning ships, azimuth thrusters optimize fuel consumption and improve vessel responsiveness in complex marine environments.

Overview of Tunnel Thrusters

Tunnel thrusters are transverse propulsion units installed in tunnels across the hull, mainly near the bow or stern, providing enhanced maneuverability at low speeds. They generate lateral thrust by directing water flow sideways, facilitating precise vessel positioning in tight spaces such as harbors or during docking. Unlike azimuth thrusters, which offer 360-degree rotation and propulsion, tunnel thrusters are fixed-direction devices primarily used for sideways control rather than forward propulsion.

Key Differences: Azimuth vs Tunnel Thrusters

Azimuth thrusters provide 360-degree rotation, enabling enhanced maneuverability and precise directional control, which is essential for dynamic vessel positioning. Tunnel thrusters are fixed in a tunnel through the hull, offering lateral thrust primarily at low speeds for docking and slow maneuvering but lack the rotational flexibility of azimuth thrusters. The key difference lies in azimuth thrusters' rotational capability versus tunnel thrusters' fixed lateral thrust, impacting their application in ship handling and dynamic positioning systems.

Maneuverability and Control Comparison

Azimuth thrusters offer superior maneuverability with 360-degree rotation, providing precise directional control and efficient thrust vectoring for dynamic vessel movement. Tunnel thrusters, installed transversely in tunnels through the hull, enhance lateral control primarily at low speeds but have limited directional flexibility compared to azimuth units. The choice between azimuth and tunnel thrusters depends on vessel operational requirements, with azimuth thrusters favored for complex navigational environments due to their enhanced control capabilities.

Installation and Design Considerations

Azimuth thrusters require hull modifications to accommodate their pod-mounted, steerable design, offering greater maneuverability and directional thrust control, ideal for dynamic positioning systems in vessels. Tunnel thrusters are installed transversely through the hull below the waterline, necessitating precise tunnel sizing to minimize drag and maximize thrust efficiency while maintaining hull integrity. The choice between azimuth and tunnel thrusters depends on vessel size, operational requirements, and installation constraints, with azimuth thrusters demanding more complex integration but providing enhanced steering capabilities.

Efficiency and Performance in Various Vessels

Azimuth thrusters provide superior maneuverability and higher propulsive efficiency in larger vessels due to their ability to rotate 360 degrees, optimizing thrust direction for varying operational conditions. Tunnel thrusters, installed transversely in shallow tunnels, offer effective lateral control primarily in smaller vessels and harbor crafts but exhibit reduced efficiency in open waters compared to azimuth systems. Performance differences are pronounced with azimuth thrusters excelling in dynamic positioning and fuel savings during complex maneuvers, while tunnel thrusters are cost-effective solutions for low-speed, close-quarter vessel control.

Maintenance and Operational Costs

Azimuth thrusters typically incur higher maintenance costs due to their complex mechanical components and steering mechanisms, which require regular inspection and lubrication. Tunnel thrusters, with simpler fixed installations inside the hull, generally offer lower operational and maintenance expenses but might increase fuel consumption during use. Choosing between the two depends on balancing the need for maneuverability against long-term maintenance budgets and energy efficiency.

Typical Applications in Marine Engineering

Azimuth thrusters are commonly employed in offshore vessels and dynamic positioning systems due to their 360-degree rotation, enabling precise maneuverability and station-keeping in complex marine environments. Tunnel thrusters are typically installed in the bow or stern of ships such as ferries and tugboats, providing lateral thrust for docking, slow-speed maneuvering, and improved control in confined waterways. Both thruster types enhance vessel responsiveness but are selected based on operational requirements, with azimuth thrusters favored for versatile thrust direction and tunnel thrusters preferred for cost-effective, fixed-direction lateral movements.

Future Trends in Thruster Technology

Future trends in thruster technology emphasize enhanced maneuverability and energy efficiency, with azimuth thrusters leading advancements due to their 360-degree rotational capability and integration with hybrid propulsion systems. Tunnel thrusters are evolving through improved hydrodynamic designs and the incorporation of electric drive units, targeting reduced noise and vibration for port maneuvering applications. Innovations in digital control systems and automation are driving increased precision and responsiveness in both azimuth and tunnel thrusters, supporting the transition to greener maritime operations.

Thrust vectoring

Azimuth thrusters provide 360-degree thrust vectoring for enhanced maneuverability, while tunnel thrusters deliver lateral thrust limited to fixed transverse directions.

360-degree maneuverability

Azimuth thrusters provide superior 360-degree maneuverability compared to tunnel thrusters due to their fully rotatable design enabling precise and flexible vessel control.

Dynamic positioning (DP)

Azimuth thrusters provide superior dynamic positioning (DP) accuracy and maneuverability compared to tunnel thrusters due to their 360-degree rotation capability and higher thrust efficiency.

Lateral propulsion

Azimuth thrusters provide superior lateral propulsion by enabling 360-degree rotation for enhanced maneuverability, while tunnel thrusters offer fixed-direction lateral thrust primarily for low-speed docking and station-keeping.

Retractable thrusters

Retractable azimuth thrusters offer superior maneuverability and efficiency compared to fixed tunnel thrusters by providing adjustable thrust direction and reduced drag during cruising.

Podded drives

Podded drives, such as azimuth thrusters, offer superior maneuverability and efficiency compared to tunnel thrusters by providing 360-degree rotational thrust and eliminating the need for rudders.

Hybrid propulsion systems

Hybrid propulsion systems integrate azimuth thrusters for enhanced maneuverability and tunnel thrusters for precise lateral control, optimizing vessel efficiency and operational flexibility.

Bow thruster efficiency

Azimuth thrusters provide superior bow thruster efficiency by offering greater maneuverability and thrust vectoring compared to the fixed-direction output of tunnel thrusters.

Propeller azimuthing

Azimuth thrusters provide 360-degree propeller azimuthing for enhanced maneuverability compared to fixed-direction tunnel thrusters limited to lateral thrust.

Transverse thrust

Azimuth thrusters provide 360-degree rotational transverse thrust for enhanced maneuverability, while tunnel thrusters deliver limited transverse thrust through fixed transverse tunnels primarily for low-speed lateral movement.

Azimuth thrusters vs Tunnel thrusters Infographic

njnir.com

njnir.com