RO-RO ships are specifically designed to transport wheeled cargo such as cars, trucks, and trailers that can be driven on and off the vessel, providing faster loading and unloading compared to container ships. Container ships carry standardized containers stacked on deck or in holds, optimizing space for diverse cargo types but requiring cranes and longer port stays. The choice between RO-RO and container ships impacts operational efficiency, cargo handling methods, and port infrastructure requirements in marine engineering logistics.

Table of Comparison

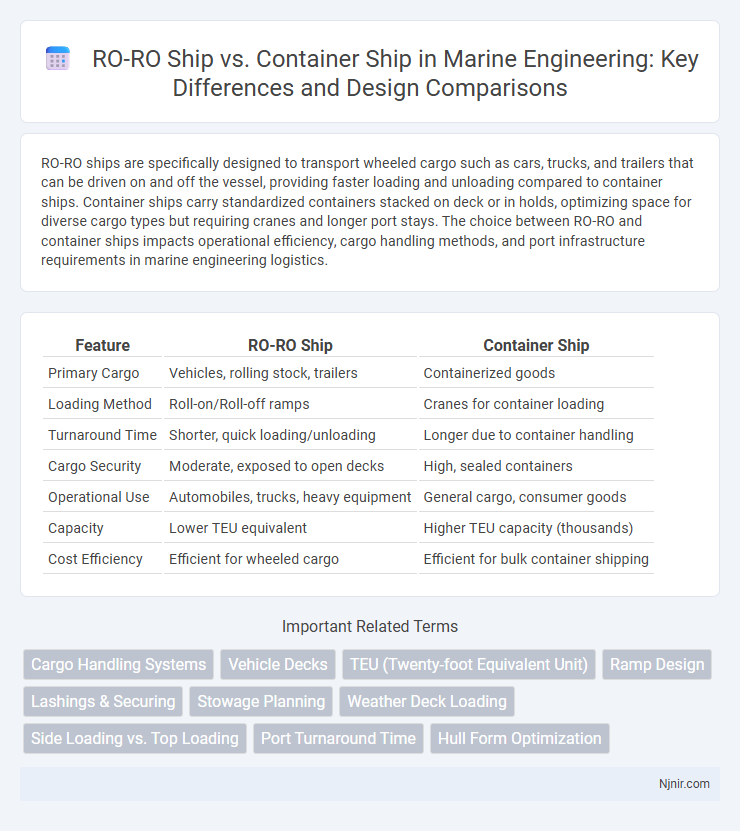

| Feature | RO-RO Ship | Container Ship |

|---|---|---|

| Primary Cargo | Vehicles, rolling stock, trailers | Containerized goods |

| Loading Method | Roll-on/Roll-off ramps | Cranes for container loading |

| Turnaround Time | Shorter, quick loading/unloading | Longer due to container handling |

| Cargo Security | Moderate, exposed to open decks | High, sealed containers |

| Operational Use | Automobiles, trucks, heavy equipment | General cargo, consumer goods |

| Capacity | Lower TEU equivalent | Higher TEU capacity (thousands) |

| Cost Efficiency | Efficient for wheeled cargo | Efficient for bulk container shipping |

Overview of RO-RO Ships and Container Ships

RO-RO ships, designed for transporting wheeled cargo such as cars, trucks, and trailers, feature built-in ramps that facilitate efficient loading and unloading directly onto the vessel. Container ships, optimized for standardized cargo containers, utilize large cranes and stack containers on deck and in the hold, enabling streamlined intermodal transportation. Both vessel types serve critical roles in global shipping, with RO-RO ships focusing on vehicles and machinery while container ships handle diverse goods in modular container units.

Design and Structural Differences

RO-RO ships feature a design optimized for vehicle transportation, with multiple built-in ramps and large open decks that facilitate efficient roll-on/roll-off operations, enhancing quick loading and unloading of wheeled cargo. In contrast, container ships are structurally composed of cellular guides designed to securely hold standardized containers stacked vertically and horizontally, maximizing cargo density and stability. The hull of a RO-RO ship is generally boxier to accommodate vehicle decks, while container ships have a more streamlined hull shape to optimize hydrodynamic efficiency for heavier, containerized loads.

Cargo Handling Methods

RO-RO ships utilize roll-on/roll-off cargo handling methods, allowing vehicles and wheeled cargo to be driven directly on and off the vessel using ramps, which significantly reduces loading and unloading time. Container ships employ crane-based handling techniques, where standardized containers are lifted and stacked using gantry cranes, enabling efficient handling of large volumes of diverse cargo. The roll-on/roll-off method is optimal for automotive and heavy machinery transport, while container ship handling supports intermodal freight movement with high cargo density and protection.

Loading and Unloading Efficiency

RO-RO ships enable rapid loading and unloading by allowing vehicles and wheeled cargo to be driven directly on and off the vessel via ramps, significantly reducing turnaround times. Container ships rely on cranes and specialized equipment to lift containers, which often requires more time and labor compared to RO-RO operations. This difference in loading and unloading efficiency makes RO-RO ships particularly advantageous for transporting automobiles and heavy machinery with quick port transitions.

Types of Goods Transported

RO-RO ships primarily transport wheeled cargo such as cars, trucks, trailers, and heavy machinery that can be driven on and off the vessel. Container ships specialize in carrying standardized cargo containers filled with diverse goods, ranging from electronics and textiles to machinery parts and consumer products. The choice between RO-RO and container ships depends on the nature of the cargo, with RO-RO ideal for vehicles and oversized equipment, while container ships accommodate a broader variety of packaged goods.

Operational Costs and Fuel Efficiency

RO-RO ships generally exhibit lower operational costs compared to container ships due to simpler cargo handling processes and faster loading and unloading times, which reduce port fees and labor expenses. Fuel efficiency varies, with container ships typically optimizing fuel usage over long distances through steady speeds, while RO-RO vessels may have higher fuel consumption per cargo unit owing to design differences and heavier ship structures. The choice between RO-RO and container ships heavily depends on cargo type, route length, and turnaround time priorities, influencing both fuel efficiency and overall operational costs.

Port Infrastructure Requirements

RO-RO ships require specialized port infrastructure with extensive ramps and linkspans enabling efficient vehicle loading and unloading, demanding robust quay structures to support heavy rolling equipment. Container ships rely on deepwater berths equipped with large gantry cranes designed for precise stacking and handling of standardized containers, necessitating expansive container yards and automated storage systems. Port facilities must adapt to these different operational needs to optimize turnaround times and ensure smooth cargo flow.

Safety and Security Considerations

RO-RO ships and container ships differ significantly in safety and security considerations due to their cargo types and stowage methods. RO-RO vessels carry wheeled cargo such as cars and trucks, which requires rigorous securing to prevent shifting during transit, while container ships stack standardized containers that are easier to secure but demand strict inspection to prevent smuggling and ensure hazardous materials are properly declared. Both ship types must adhere to the International Maritime Organization (IMO) regulations, including the SOLAS convention, to maintain fire safety, stability, and anti-piracy measures during voyages.

Environmental Impact and Regulations

RO-RO ships emit higher levels of nitrogen oxides (NOx) and particulate matter due to their frequent port calls and engine idling compared to container ships, which benefit from more fuel-efficient, steady-speed operations. Container ships generally achieve lower carbon dioxide (CO2) emissions per ton-mile through optimized hull designs and slower steaming practices mandated by the International Maritime Organization (IMO) regulations. Both vessel types must comply with IMO's MARPOL Annex VI standards, but RO-RO ships face stricter scrutiny on volatile organic compound (VOC) emissions because of cargo types, influencing the development of advanced emission control technologies.

Future Trends in RO-RO and Container Shipping

Future trends in RO-RO shipping emphasize automation and enhanced cargo tracking systems to improve turnaround times and operational efficiency, leveraging IoT and AI technologies. Container shipping is advancing towards greener solutions, including the adoption of LNG-fueled vessels and battery-electric propulsion to reduce carbon emissions, alongside blockchain integration for transparent supply chain management. Both sectors are investing in digital transformation and sustainability initiatives to meet stringent environmental regulations and increasing global trade demands.

Cargo Handling Systems

RO-RO ships utilize roll-on/roll-off ramps for efficient vehicle and wheeled cargo handling, while container ships rely on crane-operated gantry systems for precise loading and unloading of standardized containers.

Vehicle Decks

Ro-Ro ships feature multiple specialized vehicle decks designed for efficient loading and unloading of wheeled cargo, whereas container ships utilize large open holds optimized for stacking standard-sized containers.

TEU (Twenty-foot Equivalent Unit)

A container ship can carry up to 20,000 TEU, whereas RO-RO ships typically focus on transporting wheeled cargo with significantly lower TEU capacity, often below 1,000 TEU.

Ramp Design

Ramp design in RO-RO ships prioritizes robust, adjustable ramps for efficient vehicle loading and unloading, whereas container ships utilize fixed or hinged gantry cranes and container cell guides for container handling.

Lashings & Securing

RO-RO ships utilize specialized lashings and securing systems designed for wheeled cargo to prevent movement during transit, whereas container ships rely on twist locks, lashing rods, and turnbuckles to secure stacked containers efficiently.

Stowage Planning

RO-RO ship stowage planning prioritizes efficient vehicle deck space allocation and weight distribution, whereas container ship stowage planning emphasizes stack optimization, container weight segregation, and accessibility for loading and unloading.

Weather Deck Loading

RO-RO ships enable faster weather deck loading of wheeled cargo compared to container ships that rely on crane operations for containerized goods.

Side Loading vs. Top Loading

Side loading on RO-RO ships enables rapid vehicle roll-on/roll-off operations through ramps, while container ships rely on top loading using cranes for stacking containers efficiently.

Port Turnaround Time

RO-RO ships typically have shorter port turnaround times than container ships due to faster vehicle loading and unloading processes.

Hull Form Optimization

Hull form optimization for RO-RO ships emphasizes shallow draft and wide beam to maximize vehicle capacity and facilitate efficient loading, while container ships prioritize slender, deep hulls for enhanced hydrodynamic efficiency and reduced fuel consumption over long voyages.

RO-RO ship vs container ship Infographic

njnir.com

njnir.com