Air lubrication reduces friction between the ship's hull and water by creating a layer of air bubbles, significantly improving fuel efficiency and lowering emissions. Hull coatings provide a physical barrier that prevents biofouling and corrosion, maintaining hull smoothness and reducing drag. Combining air lubrication systems with advanced hull coatings offers synergistic benefits for enhanced marine vessel performance and reduced operational costs.

Table of Comparison

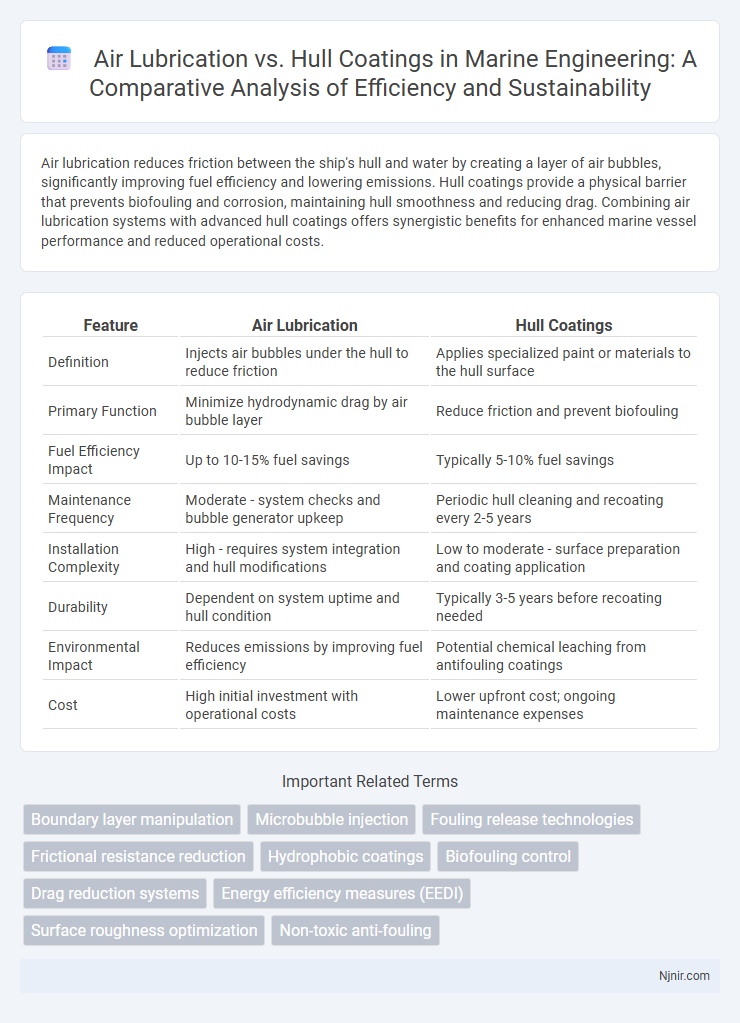

| Feature | Air Lubrication | Hull Coatings |

|---|---|---|

| Definition | Injects air bubbles under the hull to reduce friction | Applies specialized paint or materials to the hull surface |

| Primary Function | Minimize hydrodynamic drag by air bubble layer | Reduce friction and prevent biofouling |

| Fuel Efficiency Impact | Up to 10-15% fuel savings | Typically 5-10% fuel savings |

| Maintenance Frequency | Moderate - system checks and bubble generator upkeep | Periodic hull cleaning and recoating every 2-5 years |

| Installation Complexity | High - requires system integration and hull modifications | Low to moderate - surface preparation and coating application |

| Durability | Dependent on system uptime and hull condition | Typically 3-5 years before recoating needed |

| Environmental Impact | Reduces emissions by improving fuel efficiency | Potential chemical leaching from antifouling coatings |

| Cost | High initial investment with operational costs | Lower upfront cost; ongoing maintenance expenses |

Introduction to Air Lubrication and Hull Coatings

Air lubrication reduces ship hull friction by creating a continuous layer of microbubbles between the hull and seawater, lowering drag and improving fuel efficiency. Hull coatings, typically specialized anti-fouling or low-friction paints, prevent marine organism attachment and reduce surface roughness to enhance hydrodynamic performance. Both technologies aim to optimize vessel efficiency but differ in mechanism: air lubrication modifies fluid dynamics while hull coatings provide a physical barrier.

Principles of Air Lubrication Technology

Air lubrication technology reduces ship hull friction by injecting a continuous layer of microbubbles or a thin air film beneath the hull, creating a low-resistance cushion between the water and the surface. This principle minimizes hydrodynamic drag through decreased wetted surface area and turbulence, leading to improved fuel efficiency and reduced emissions. Unlike hull coatings that rely on surface properties to decrease biofouling and friction passively, air lubrication actively modifies the water-hull interface to achieve significant drag reduction.

Overview of Advanced Hull Coatings

Advanced hull coatings utilize specialized polymers and nanotechnology to reduce drag by minimizing biofouling and surface roughness on ship hulls. These coatings enhance fuel efficiency and lower greenhouse gas emissions by maintaining a cleaner hull surface compared to traditional paints. Innovations include silicone-based and fluoropolymer coatings that provide long-lasting durability and resistance to marine organisms, contributing to optimized vessel performance and reduced maintenance costs.

Comparative Energy Efficiency

Air lubrication systems reduce friction by injecting air bubbles beneath the hull, cutting energy consumption by up to 10-15% compared to traditional hull coatings that primarily rely on smooth surfaces to minimize drag. Hull coatings, including silicone-based or antifouling paints, offer moderate energy efficiency improvements but often degrade over time, necessitating frequent maintenance. Studies show that integrating air lubrication with advanced hull coatings can amplify fuel savings, making this hybrid approach superior for long-term energy optimization in maritime vessels.

Impact on Fuel Consumption and Emissions

Air lubrication systems reduce fuel consumption by creating a layer of air bubbles along the hull, decreasing frictional resistance between the ship's hull and water, which can lower fuel use by up to 10%. Hull coatings, particularly advanced silicone or fluoropolymer-based coatings, minimize surface roughness and biofouling, leading to smoother water flow and fuel savings typically between 5% and 8%. Combining air lubrication with optimized hull coatings can maximize energy efficiency, significantly cutting CO2 emissions and operational costs for marine vessels.

Installation and Maintenance Considerations

Air lubrication systems require complex installation involving onboard compressors and piping, often necessitating dry-dock time and specialized expertise, whereas hull coatings are applied during routine dry-docking or in specialized facilities with less technical complexity. Maintenance for air lubrication involves regular system checks, compressor upkeep, and potential refurbishment of air diffusers, resulting in higher operational costs compared to hull coatings, which primarily need periodic inspections and touch-ups to maintain antifouling and hydrophobic properties. The choice between air lubrication and hull coatings significantly impacts lifecycle maintenance scheduling, cost allocation, and vessel downtime management.

Operational Limitations and Challenges

Air lubrication systems face operational limitations such as sensitivity to sea conditions and energy consumption for air compression, impacting their effectiveness on rough waters. Hull coatings, while providing long-term protection against biofouling and corrosion, encounter challenges related to coating degradation, maintenance frequency, and environmental regulations. Both technologies require careful consideration of ship type, operating profiles, and maintenance strategies to optimize performance and cost-efficiency.

Cost-Benefit Analysis of Both Solutions

Air lubrication systems reduce frictional resistance on ship hulls by creating a layer of bubbles, resulting in fuel savings of up to 10-15% but require higher initial investment and maintenance costs. Hull coatings, such as silicone or fluoropolymer-based paints, offer a lower upfront cost and reduce biofouling, leading to fuel efficiency improvements of approximately 5-8%, with longer intervals between dry-docking. Evaluating cost-benefit factors depends on vessel type, operating profile, and maintenance capabilities, where air lubrication suits large, high-speed vessels, while advanced hull coatings provide cost-effective benefits for smaller or slower ships.

Environmental Sustainability and Compliance

Air lubrication systems reduce friction by injecting air bubbles along a ship's hull, significantly lowering fuel consumption and CO2 emissions, promoting environmental sustainability. Hull coatings, designed with eco-friendly biocides or non-toxic materials, prevent biofouling and maintain vessel efficiency without harming marine ecosystems. Both technologies support compliance with IMO regulations on greenhouse gas emissions and ballast water management, advancing greener shipping practices.

Future Trends in Hull Friction Reduction Technology

Future trends in hull friction reduction technology emphasize integrating air lubrication systems with advanced hull coatings to maximize hydrodynamic efficiency. Innovations in nanoscale and biomimetic coatings aim to further reduce surface roughness and biofouling, enhancing the effectiveness of air bubble layers beneath the hull. Combining these technologies could lead to significant fuel savings and lower emissions, driving the maritime industry's shift toward sustainable vessel operations.

Boundary layer manipulation

Air lubrication reduces friction by injecting microbubbles along the hull to manipulate the boundary layer, while hull coatings alter surface roughness and hydrophobicity to minimize drag in marine vessels.

Microbubble injection

Microbubble injection in air lubrication reduces hull friction more effectively than traditional hull coatings by creating a persistent low-resistance layer of air bubbles along the ship's surface.

Fouling release technologies

Fouling release technologies in air lubrication systems reduce drag by maintaining a continuous air layer on the hull, whereas hull coatings employ specialized low-friction materials to prevent marine organism attachment and improve vessel efficiency.

Frictional resistance reduction

Air lubrication reduces frictional resistance by creating a layer of air bubbles along the hull, whereas hull coatings minimize resistance by creating a smoother surface and preventing biofouling.

Hydrophobic coatings

Hydrophobic hull coatings reduce drag by repelling water and fouling, while air lubrication systems create a layer of air to minimize friction between the ship's hull and water, both enhancing fuel efficiency and performance.

Biofouling control

Air lubrication reduces biofouling by minimizing direct hull-water contact and friction, while hull coatings use specialized biocidal or fouling-release materials to prevent organism attachment.

Drag reduction systems

Air lubrication systems reduce hull drag by creating a persistent layer of microbubbles along the ship's bottom, whereas hull coatings rely on specialized materials to minimize surface friction and biofouling, both enhancing fuel efficiency in drag reduction systems.

Energy efficiency measures (EEDI)

Air lubrication reduces hull friction by creating a layer of air bubbles, enhancing energy efficiency and lowering EEDI compared to traditional hull coatings that rely on smooth surfaces to minimize drag.

Surface roughness optimization

Air lubrication reduces surface roughness by creating a microbubble layer that minimizes friction, whereas hull coatings optimize surface smoothness through advanced materials and textures to decrease drag.

Non-toxic anti-fouling

Non-toxic anti-fouling air lubrication systems reduce hull friction by creating a persistent air layer, offering an eco-friendly alternative to traditional chemical-based hull coatings.

Air lubrication vs Hull coatings Infographic

njnir.com

njnir.com