Air lubrication reduces friction between the ship hull and water by creating a layer of air bubbles, significantly improving fuel efficiency and reducing emissions. Hull coating involves applying specialized materials to the hull's surface to minimize roughness and prevent marine fouling, which also enhances vessel speed and fuel economy. Comparing both, air lubrication offers dynamic friction reduction without surface alteration, while hull coatings provide long-lasting protection but may require periodic maintenance.

Table of Comparison

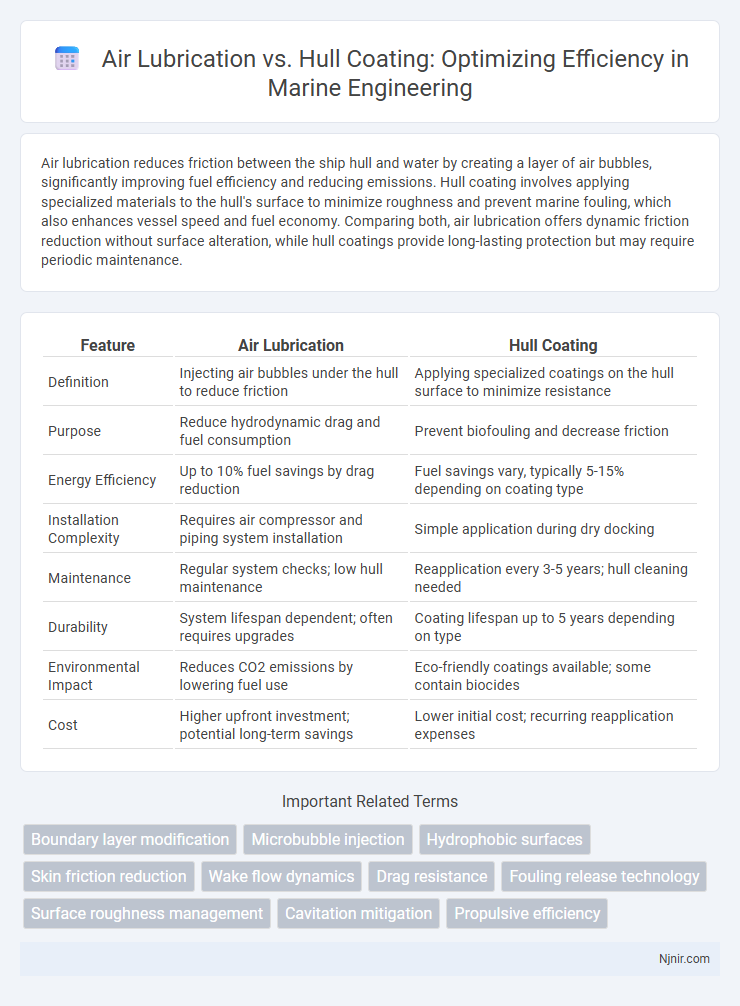

| Feature | Air Lubrication | Hull Coating |

|---|---|---|

| Definition | Injecting air bubbles under the hull to reduce friction | Applying specialized coatings on the hull surface to minimize resistance |

| Purpose | Reduce hydrodynamic drag and fuel consumption | Prevent biofouling and decrease friction |

| Energy Efficiency | Up to 10% fuel savings by drag reduction | Fuel savings vary, typically 5-15% depending on coating type |

| Installation Complexity | Requires air compressor and piping system installation | Simple application during dry docking |

| Maintenance | Regular system checks; low hull maintenance | Reapplication every 3-5 years; hull cleaning needed |

| Durability | System lifespan dependent; often requires upgrades | Coating lifespan up to 5 years depending on type |

| Environmental Impact | Reduces CO2 emissions by lowering fuel use | Eco-friendly coatings available; some contain biocides |

| Cost | Higher upfront investment; potential long-term savings | Lower initial cost; recurring reapplication expenses |

Introduction to Air Lubrication and Hull Coating

Air lubrication reduces friction between a ship's hull and seawater by creating a carpet of microbubbles, enhancing fuel efficiency and decreasing carbon emissions. Hull coating involves applying specialized paints or materials that minimize biofouling and surface roughness, leading to improved hydrodynamics and durability. Both technologies aim to optimize vessel performance by lowering drag, with air lubrication focusing on active bubble injection and hull coating relying on passive surface treatments.

Principles of Air Lubrication Technology

Air lubrication technology reduces ship hull friction by generating a continuous layer of microbubbles beneath the vessel, minimizing direct water contact and drag. This system relies on compressors and air diffusers to produce a fine air layer that enhances fuel efficiency and lowers emissions. Unlike traditional hull coatings that depend on surface chemistry to prevent biofouling, air lubrication actively alters the water-hull interface for significant hydrodynamic benefits.

Types of Hull Coating Solutions

Hull coating solutions include antifouling paints, silicone-based foul-release coatings, and advanced air lubrication systems, each designed to reduce friction between the ship's hull and seawater. Traditional antifouling coatings use biocides to prevent marine organism growth, while foul-release coatings create a slick surface that deters attachment without harmful chemicals. Air lubrication systems complement these coatings by injecting microscopic air bubbles along the hull, further minimizing hydrodynamic drag and enhancing fuel efficiency.

Energy Efficiency Comparison

Air lubrication systems reduce frictional resistance by generating a layer of microbubbles along the hull, leading to energy savings of up to 10-15% compared to traditional hull coatings. Hull coatings primarily minimize surface roughness and biofouling, improving energy efficiency by around 5-8%, but their effectiveness diminishes over time due to wear and marine growth. Combining air lubrication with advanced hull coatings can maximize energy efficiency, significantly lowering fuel consumption and carbon emissions for maritime vessels.

Impact on Hull Resistance and Drag Reduction

Air lubrication systems reduce hull resistance by creating a thin layer of air bubbles along the ship's bottom, significantly decreasing water friction and improving fuel efficiency. Hull coatings, particularly advanced low-friction and antifouling paints, minimize drag by creating a smoother surface that resists marine growth and reduces skin friction. Combining air lubrication with optimized hull coatings can offer synergistic drag reduction benefits, leading to substantial improvements in vessel performance and lower operational costs.

Installation and Maintenance Requirements

Air lubrication systems require complex installation involving air compressors, piping, and hull modifications, demanding significant upfront engineering and downtime. Maintenance involves regular inspection of compressors, air distribution mechanisms, and monitoring for system leaks to ensure efficiency. Hull coatings, by contrast, install through surface preparation and application, often done during dry-docking, with maintenance focused on periodic reapplication to maintain antifouling and friction-reducing properties.

Environmental Benefits and Concerns

Air lubrication systems reduce hull friction by creating a layer of air bubbles, significantly decreasing fuel consumption and greenhouse gas emissions compared to traditional hull coatings. Hull coatings, especially biocidal antifouling paints, can leach toxic substances into marine ecosystems, posing risks to aquatic life despite their effectiveness in preventing biofouling. Air lubrication offers a non-toxic alternative with lower environmental impact, aligning with global maritime emission reduction goals and minimizing harmful chemical discharge.

Lifecycle Cost Analysis

Air lubrication systems reduce friction by creating a layer of air bubbles along the hull, leading to significant fuel savings and lower operational costs over a vessel's lifecycle compared to traditional hull coatings. Hull coatings require periodic application and maintenance, adding to lifecycle expenses through material and labor costs, whereas air lubrication systems demand upfront investment with lower recurring maintenance costs. Lifecycle cost analysis shows air lubrication can provide superior cost-efficiency and environmental benefits over typical anti-fouling hull coatings, especially for high-utilization vessels.

Operational Limitations and Scalability

Air lubrication systems reduce friction by creating a carpet of bubbles along the hull, but their effectiveness can diminish at lower speeds and in rough sea conditions, limiting operational consistency. Hull coatings provide a passive solution by minimizing biofouling and drag, yet their performance degrades over time and requires periodic maintenance, impacting long-term scalability. Scaling air lubrication to larger vessels involves complex retrofitting and increased energy consumption, whereas hull coatings offer easier application and scalability for varied ship sizes but with less dynamic drag reduction.

Future Trends in Hull Friction Reduction Technologies

Future trends in hull friction reduction technologies emphasize the integration of advanced air lubrication systems that create a persistent air film along the hull surface, significantly reducing hydrodynamic drag and enhancing fuel efficiency. Innovations in hull coatings involve the development of biomimetic and nanostructured materials that minimize biofouling and surface roughness, thereby lowering frictional resistance in diverse marine environments. Hybrid solutions combining air lubrication with next-generation coatings are projected to optimize vessel performance and reduce greenhouse gas emissions in the shipping industry.

Boundary layer modification

Air lubrication reduces friction by injecting microbubbles beneath the hull to modify the boundary layer, whereas hull coating alters the surface texture and chemistry to minimize drag and biofouling.

Microbubble injection

Microbubble injection in air lubrication systems reduces hull friction more effectively than traditional hull coatings by creating a persistent lubricating layer that minimizes direct water contact.

Hydrophobic surfaces

Hydrophobic hull coatings reduce drag by repelling water, whereas air lubrication systems create a low-friction air layer, both enhancing vessel efficiency through different surface interaction mechanisms.

Skin friction reduction

Air lubrication reduces skin friction on ship hulls by creating a layer of microbubbles that decreases water resistance, while hull coatings primarily minimize friction through smooth, low-friction surfaces and biofouling prevention.

Wake flow dynamics

Air lubrication reduces friction by injecting microbubbles to alter wake flow dynamics, whereas hull coating modifies surface texture to minimize boundary layer resistance and turbulence in the wake.

Drag resistance

Air lubrication reduces drag resistance by creating a layer of air bubbles on the hull surface, whereas hull coating minimizes drag through smooth, antifouling materials that prevent biofouling buildup.

Fouling release technology

Fouling release technology in hull coatings reduces drag and biofouling by creating a slick surface that minimizes organism adhesion, while air lubrication systems reduce hydrodynamic resistance by generating a layer of microbubbles along the hull, both enhancing vessel fuel efficiency and performance.

Surface roughness management

Air lubrication significantly reduces surface roughness by creating a uniform air layer on the hull, enhancing frictional resistance more effectively than traditional hull coatings.

Cavitation mitigation

Air lubrication reduces cavitation by creating a lubricating layer of microbubbles between the hull and water, whereas hull coatings primarily minimize cavitation damage by enhancing surface smoothness and resistance to erosion.

Propulsive efficiency

Air lubrication reduces friction by generating a stable air layer along the hull, significantly improving propulsive efficiency compared to traditional hull coatings that primarily minimize surface roughness.

Air lubrication vs Hull coating Infographic

njnir.com

njnir.com