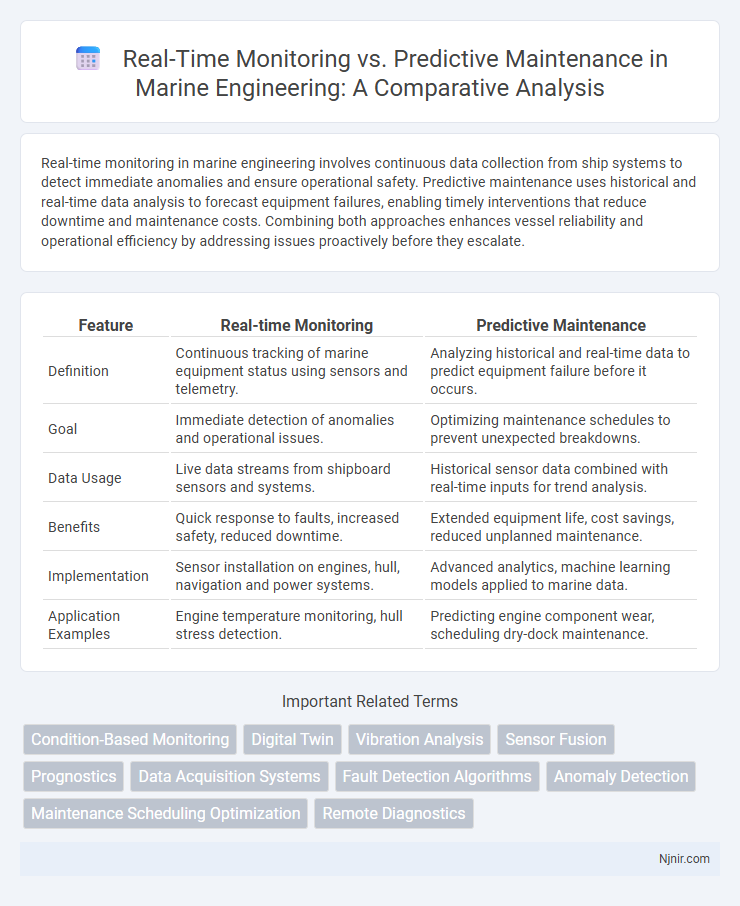

Real-time monitoring in marine engineering involves continuous data collection from ship systems to detect immediate anomalies and ensure operational safety. Predictive maintenance uses historical and real-time data analysis to forecast equipment failures, enabling timely interventions that reduce downtime and maintenance costs. Combining both approaches enhances vessel reliability and operational efficiency by addressing issues proactively before they escalate.

Table of Comparison

| Feature | Real-time Monitoring | Predictive Maintenance |

|---|---|---|

| Definition | Continuous tracking of marine equipment status using sensors and telemetry. | Analyzing historical and real-time data to predict equipment failure before it occurs. |

| Goal | Immediate detection of anomalies and operational issues. | Optimizing maintenance schedules to prevent unexpected breakdowns. |

| Data Usage | Live data streams from shipboard sensors and systems. | Historical sensor data combined with real-time inputs for trend analysis. |

| Benefits | Quick response to faults, increased safety, reduced downtime. | Extended equipment life, cost savings, reduced unplanned maintenance. |

| Implementation | Sensor installation on engines, hull, navigation and power systems. | Advanced analytics, machine learning models applied to marine data. |

| Application Examples | Engine temperature monitoring, hull stress detection. | Predicting engine component wear, scheduling dry-dock maintenance. |

Introduction to Real-Time Monitoring and Predictive Maintenance

Real-time monitoring continuously tracks equipment performance using sensors and IoT technology to detect anomalies as they occur, enabling immediate response to potential issues. Predictive maintenance leverages historical data, machine learning algorithms, and statistical models to forecast equipment failures before they happen, optimizing maintenance schedules and reducing downtime. Integrating real-time monitoring data with predictive analytics enhances accuracy in maintenance planning and asset management.

Core Principles of Real-Time Monitoring in Marine Engineering

Real-time monitoring in marine engineering involves continuous data collection from sensors installed on critical machinery and systems to detect anomalies and performance deviations instantaneously. This core principle enables immediate response to operational changes, ensuring safety, minimizing downtime, and optimizing vessel performance by providing up-to-the-minute status updates. Unlike predictive maintenance, which relies on historical data analysis and trend forecasting, real-time monitoring prioritizes active surveillance and rapid decision-making for ongoing system health.

Predictive Maintenance: Concepts and Applications at Sea

Predictive maintenance at sea leverages sensor data and AI algorithms to forecast equipment failures before they occur, enhancing operational efficiency and safety on maritime vessels. By continuously analyzing engine performance, hull integrity, and environmental conditions, predictive maintenance minimizes unplanned downtime and reduces costly repairs during voyages. This approach enables proactive decision-making, optimizing maintenance schedules and extending the lifespan of critical ship components.

Key Technologies Powering Real-Time Monitoring Systems

Real-time monitoring systems rely heavily on IoT sensors, edge computing, and advanced data analytics to continuously track equipment performance and operational conditions. These technologies enable instantaneous data collection, processing, and visualization, facilitating immediate detection of anomalies and system faults. Machine learning algorithms integrated into real-time monitoring platforms enhance decision-making by providing actionable insights from real-time data streams, improving asset reliability and reducing downtime.

Data Analytics and Machine Learning in Predictive Maintenance

Predictive maintenance leverages advanced data analytics and machine learning algorithms to analyze historical and real-time sensor data, identifying patterns and predicting equipment failures before they occur. Real-time monitoring continuously tracks asset conditions, but predictive maintenance adds value by using predictive models to optimize maintenance schedules and minimize unplanned downtime. Machine learning techniques such as anomaly detection, regression analysis, and classification enhance the accuracy of failure predictions, enabling smarter and cost-effective maintenance strategies.

Comparative Benefits: Real-Time Monitoring vs Predictive Maintenance

Real-time monitoring provides continuous data tracking to detect immediate equipment issues and minimize downtime, optimizing operational efficiency through instant alerts. Predictive maintenance uses advanced analytics and machine learning to forecast potential failures, enabling planned interventions that reduce unexpected breakdowns and extend asset lifespan. Combining both strategies enhances asset reliability by balancing immediate problem resolution with long-term failure prevention.

Challenges of Implementing Monitoring Strategies in Marine Environments

Real-time monitoring in marine environments faces challenges such as harsh weather conditions, saltwater corrosion, and limited access to power and communication infrastructure, which can affect sensor reliability and data transmission. Predictive maintenance requires advanced data analytics and machine learning algorithms that depend on high-quality, continuous data streams often disrupted in offshore settings. Both approaches demand robust, corrosion-resistant equipment and effective integration with existing maritime systems to ensure accurate, timely assessments and reduce downtime.

Cost Analysis and ROI for Marine Asset Management

Real-time monitoring in marine asset management offers immediate detection of equipment anomalies, reducing downtime and emergency repair costs through continuous sensor data analysis. Predictive maintenance leverages historical and real-time data with advanced algorithms to forecast potential failures, optimizing maintenance scheduling and extending asset lifespan, which significantly enhances ROI by minimizing unnecessary maintenance expenses. Cost analysis reveals real-time monitoring's lower upfront investment, while predictive maintenance delivers higher long-term savings and asset reliability, making it a strategic choice for maximizing financial efficiency in marine operations.

Case Studies: Successful Deployments Onboard Vessels

Case studies highlight real-time monitoring systems onboard vessels successfully detecting early signs of equipment failure, reducing downtime by up to 30%. Predictive maintenance models, using sensor data and machine learning algorithms, have enabled fleets like Maersk and Carnival to optimize maintenance schedules, cutting costs by 25% and improving operational efficiency. These deployments demonstrate enhanced safety and reliability in maritime operations through continuous data analysis and proactive interventions.

Future Trends in Marine Maintenance and Monitoring

Real-time monitoring in marine maintenance enables continuous data collection from vessel systems, enhancing immediate fault detection and operational efficiency. Predictive maintenance leverages advanced analytics and machine learning models to anticipate equipment failures, reducing downtime and maintenance costs. Future trends indicate increased integration of IoT sensors, AI-driven predictive algorithms, and digital twins for comprehensive, proactive marine asset management.

Condition-Based Monitoring

Real-time condition-based monitoring continuously tracks equipment performance metrics to detect anomalies early, enabling predictive maintenance that reduces downtime and extends asset lifespan.

Digital Twin

Digital Twin technology enables real-time monitoring by creating dynamic virtual replicas of assets, enhancing predictive maintenance through advanced simulations and data analytics for early fault detection and optimized operational performance.

Vibration Analysis

Vibration analysis enables real-time monitoring by detecting abnormal machine vibrations instantly while predictive maintenance uses vibration data trends to forecast potential equipment failures before they occur.

Sensor Fusion

Sensor fusion enhances real-time monitoring and predictive maintenance by integrating data from multiple sensors to improve fault detection accuracy and early anomaly prediction.

Prognostics

Prognostics in predictive maintenance utilize real-time monitoring data to forecast equipment failures and optimize maintenance schedules.

Data Acquisition Systems

Real-time monitoring employs data acquisition systems to continuously capture and analyze equipment parameters for immediate fault detection, while predictive maintenance uses these systems to gather historical data and apply algorithms for forecasting potential failures.

Fault Detection Algorithms

Fault detection algorithms in real-time monitoring analyze live sensor data to identify equipment anomalies instantly, while predictive maintenance uses historical and real-time data to forecast faults before they occur, optimizing maintenance schedules and reducing downtime.

Anomaly Detection

Real-time monitoring enables immediate anomaly detection through continuous data analysis, while predictive maintenance leverages historical and sensor data to forecast potential failures before anomalies occur.

Maintenance Scheduling Optimization

Real-time monitoring enhances maintenance scheduling optimization by providing immediate data on equipment conditions, while predictive maintenance uses historical and real-time data analytics to forecast failures and schedule proactive interventions.

Remote Diagnostics

Remote diagnostics enhances predictive maintenance by analyzing real-time monitoring data to detect potential equipment failures before they occur.

Real-time monitoring vs Predictive maintenance Infographic

njnir.com

njnir.com