Electronic engine control in marine engineering offers precise fuel management and real-time monitoring, enhancing engine efficiency and reducing emissions. Mechanical engine control relies on manual adjustments and physical linkages, which can lead to slower response times and less accurate fuel delivery. Advances in electronic systems improve reliability and enable integration with advanced diagnostics and automated ship operations, surpassing the capabilities of traditional mechanical controls.

Table of Comparison

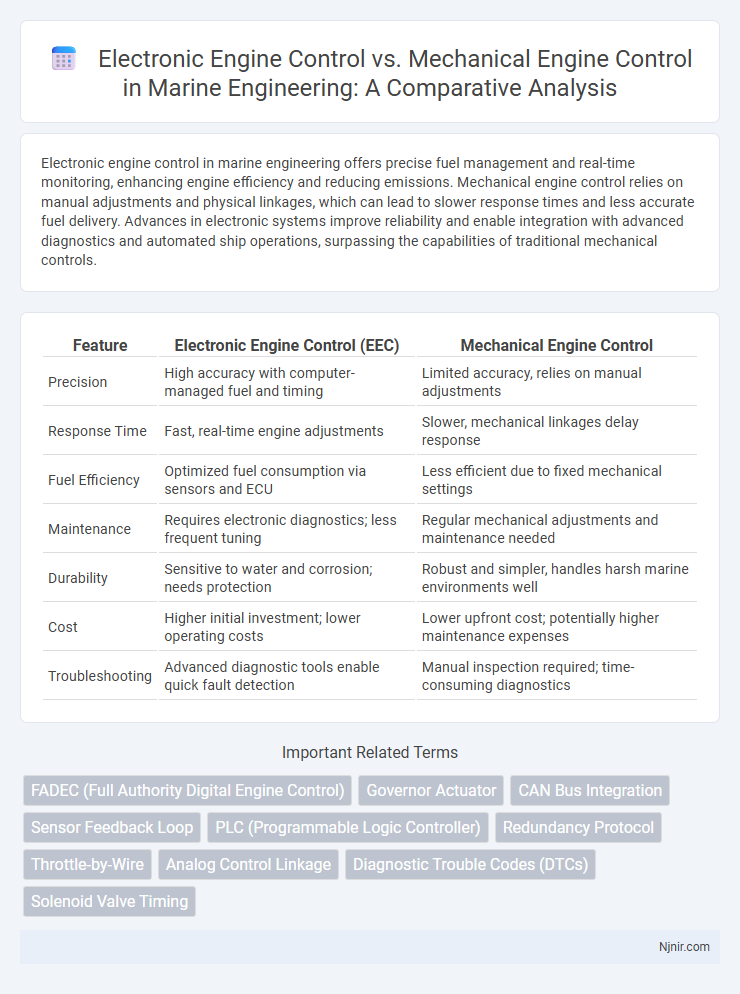

| Feature | Electronic Engine Control (EEC) | Mechanical Engine Control |

|---|---|---|

| Precision | High accuracy with computer-managed fuel and timing | Limited accuracy, relies on manual adjustments |

| Response Time | Fast, real-time engine adjustments | Slower, mechanical linkages delay response |

| Fuel Efficiency | Optimized fuel consumption via sensors and ECU | Less efficient due to fixed mechanical settings |

| Maintenance | Requires electronic diagnostics; less frequent tuning | Regular mechanical adjustments and maintenance needed |

| Durability | Sensitive to water and corrosion; needs protection | Robust and simpler, handles harsh marine environments well |

| Cost | Higher initial investment; lower operating costs | Lower upfront cost; potentially higher maintenance expenses |

| Troubleshooting | Advanced diagnostic tools enable quick fault detection | Manual inspection required; time-consuming diagnostics |

Introduction to Engine Control Systems in Marine Engineering

Electronic engine control systems in marine engineering offer precise fuel injection timing, improved engine efficiency, and real-time monitoring compared to traditional mechanical controls. These systems utilize sensors and actuators to optimize combustion and reduce emissions, enhancing overall vessel performance. Advanced electronic controls also provide diagnostic capabilities, enabling proactive maintenance and minimizing operational downtime.

Fundamentals of Mechanical Engine Control

Mechanical engine control relies on physical linkages, cams, and levers to regulate fuel injection, ignition timing, and throttle position, ensuring engine responsiveness through direct mechanical interactions. The fundamental components include the camshaft, throttle linkage, and centrifugal governors, which operate based on rotational speed and mechanical feedback without electronic sensors. This system offers simplicity and robustness but lacks the precision and adaptability of electronic engine control units (ECUs) that employ sensors and computer algorithms for optimized performance and emissions management.

Key Components of Electronic Engine Control

Electronic engine control systems utilize key components such as sensors (oxygen, temperature, and throttle position sensors), an Engine Control Unit (ECU), and actuators to optimize fuel injection and ignition timing for better efficiency and emissions control. The ECU processes real-time data from multiple sensors to continuously adjust engine parameters, enhancing performance and fuel economy compared to mechanical systems. In contrast, mechanical engine control relies on fixed components like carburetors and mechanical governors that lack adaptive precision and feedback capabilities.

Performance Comparison: Electronic vs. Mechanical Controls

Electronic engine control systems provide precise fuel injection and ignition timing adjustments, resulting in improved fuel efficiency and reduced emissions compared to mechanical controls. Mechanical engine controls rely on physical linkages and fixed settings, which limit responsiveness and adaptability under varying operating conditions. Advanced electronic controls enable real-time monitoring and optimization, delivering superior engine performance and smoother power delivery versus traditional mechanical methods.

Fuel Efficiency and Emissions Management

Electronic engine control systems optimize fuel injection timing and air-fuel mixture with high precision, significantly enhancing fuel efficiency compared to traditional mechanical controls. These systems utilize real-time sensor data to minimize fuel consumption and reduce harmful emissions such as NOx and CO2. Mechanical engine controls, reliant on fixed settings and mechanical linkages, lack adaptive capabilities, resulting in less efficient fuel usage and higher emission levels.

Reliability and Maintenance Considerations

Electronic engine control systems enhance reliability by providing precise fuel injection and ignition timing, reducing engine wear and improving performance consistency compared to mechanical controls. Maintenance is streamlined through advanced diagnostics and fewer moving parts, minimizing the frequency of repairs and adjustments traditionally required in mechanical systems. However, electronic controls depend on sensors and software, which may require specialized troubleshooting and occasional updates to maintain optimal function.

Integration with Modern Navigation and Automation

Electronic engine control systems offer seamless integration with modern navigation and automation technologies by enabling real-time data exchange and precise engine management, optimizing fuel efficiency and performance. Mechanical engine controls, limited by manual adjustments and lack of electronic interfaces, struggle to synchronize with GPS-based navigation or automated vessel systems. Advanced electronic controls support automated route adjustments and adaptive engine responses, enhancing overall vessel operational efficiency and safety.

Troubleshooting and Diagnostics Capabilities

Electronic engine control systems offer advanced troubleshooting and diagnostics capabilities through onboard sensors and real-time data monitoring, enabling precise fault detection and quicker issue resolution. Mechanical engine control relies on manual inspection and basic diagnostic tools, which can prolong fault identification and reduce diagnostic accuracy. Electronic controls also support software-based fault codes and predictive maintenance alerts, improving overall engine reliability and service efficiency.

Cost Implications and Lifecycle Management

Electronic engine control systems typically have higher upfront costs due to advanced sensors, microprocessors, and software integration, but they enable more precise fuel management and emissions control, reducing operational expenses over time. Mechanical engine control, while initially cheaper and simpler to maintain, often incurs higher long-term costs from increased fuel consumption, frequent adjustments, and wear-related repairs. Lifecycle management of electronic controls benefits from easier diagnostics, remote updates, and improved component longevity, contrasting with mechanical systems that rely on manual tuning and physical replacements.

Future Trends in Marine Engine Control Technology

Future trends in marine engine control technology emphasize the shift from mechanical engine control to electronic engine control systems, driven by advancements in sensor integration and real-time data analytics. Electronic engine control enhances fuel efficiency, reduces emissions, and enables predictive maintenance through IoT connectivity and AI algorithms. The adoption of digital twins and cloud-based monitoring platforms further optimizes engine performance and supports regulatory compliance in the maritime industry.

FADEC (Full Authority Digital Engine Control)

FADEC (Full Authority Digital Engine Control) offers superior precision, efficiency, and reliability compared to traditional mechanical engine control by digitally managing all engine functions for optimized performance and reduced pilot workload.

Governor Actuator

Electronic engine control uses advanced governor actuators to provide precise, real-time fuel regulation and engine speed management, outperforming traditional mechanical governor actuators in responsiveness and efficiency.

CAN Bus Integration

Electronic engine control systems enable advanced CAN Bus integration for real-time data exchange and diagnostics, unlike traditional mechanical engine control which lacks communication network capabilities.

Sensor Feedback Loop

Electronic engine control utilizes advanced sensor feedback loops for real-time engine performance adjustments, whereas mechanical engine control relies on fixed, less responsive mechanisms without continuous sensor input.

PLC (Programmable Logic Controller)

Programmable Logic Controllers (PLCs) in electronic engine control enhance precision, adaptability, and real-time monitoring compared to traditional mechanical engine control systems.

Redundancy Protocol

Electronic engine control systems implement advanced redundancy protocols such as dual-channel sensors and fail-safe communication buses to enhance reliability compared to traditional mechanical engine control systems that rely on physical redundancies and manual oversight.

Throttle-by-Wire

Throttle-by-Wire technology in electronic engine control offers precise acceleration response, improved fuel efficiency, and enhanced emissions management compared to traditional mechanical engine control systems.

Analog Control Linkage

Analog control linkage in mechanical engine control relies on physical connections for throttle regulation, whereas electronic engine control uses sensors and actuators for precise, real-time fuel and air mixture adjustments.

Diagnostic Trouble Codes (DTCs)

Electronic engine control provides precise Diagnostic Trouble Codes (DTCs) enabling accurate fault identification, whereas mechanical engine control lacks standardized DTC generation, hindering efficient diagnostics.

Solenoid Valve Timing

Electronic engine control optimizes solenoid valve timing with precise, real-time adjustments improving fuel efficiency and emissions, whereas mechanical engine control relies on fixed, less adaptable valve timing mechanisms.

electronic engine control vs mechanical engine control Infographic

njnir.com

njnir.com