Podded propulsion offers enhanced maneuverability and efficiency compared to traditional shaftline propulsion by integrating electric motors within the propeller units, reducing mechanical losses and noise. Shaftline propulsion remains favored for its proven reliability and simpler maintenance in large vessels operating at consistent speeds. Selecting between podded and shaftline propulsion depends on vessel type, operational demands, and maintenance infrastructure considerations.

Table of Comparison

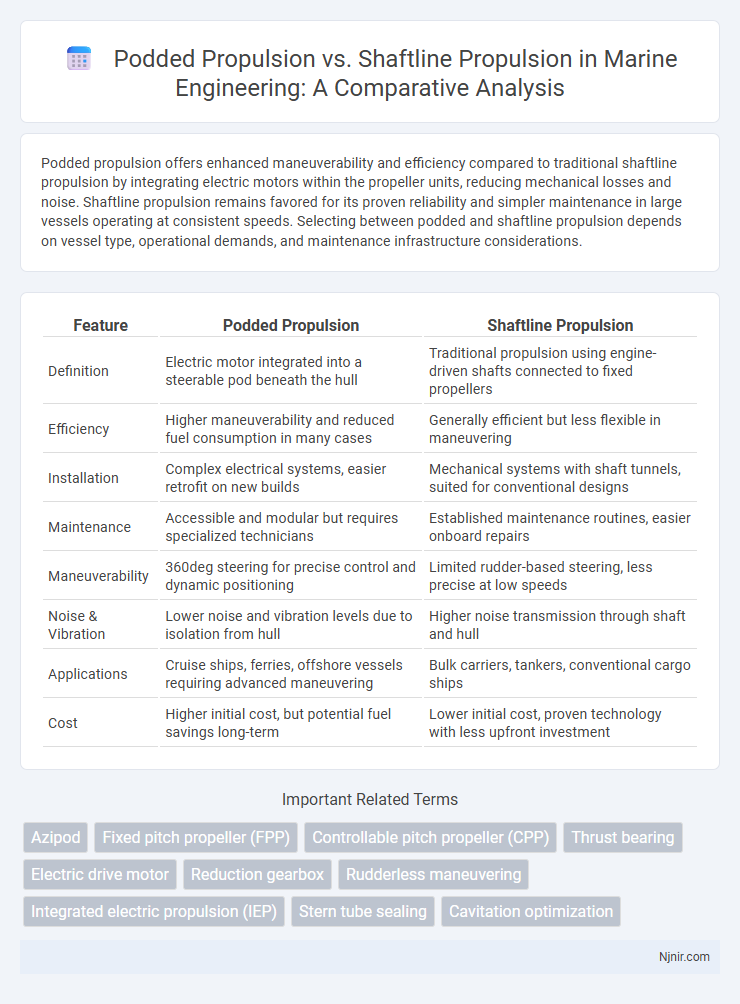

| Feature | Podded Propulsion | Shaftline Propulsion |

|---|---|---|

| Definition | Electric motor integrated into a steerable pod beneath the hull | Traditional propulsion using engine-driven shafts connected to fixed propellers |

| Efficiency | Higher maneuverability and reduced fuel consumption in many cases | Generally efficient but less flexible in maneuvering |

| Installation | Complex electrical systems, easier retrofit on new builds | Mechanical systems with shaft tunnels, suited for conventional designs |

| Maintenance | Accessible and modular but requires specialized technicians | Established maintenance routines, easier onboard repairs |

| Maneuverability | 360deg steering for precise control and dynamic positioning | Limited rudder-based steering, less precise at low speeds |

| Noise & Vibration | Lower noise and vibration levels due to isolation from hull | Higher noise transmission through shaft and hull |

| Applications | Cruise ships, ferries, offshore vessels requiring advanced maneuvering | Bulk carriers, tankers, conventional cargo ships |

| Cost | Higher initial cost, but potential fuel savings long-term | Lower initial cost, proven technology with less upfront investment |

Introduction to Ship Propulsion Systems

Podded propulsion systems integrate electric motors within steerable pods, delivering enhanced maneuverability and improved fuel efficiency compared to traditional shaftline propulsion, which relies on long shafts transmitting power from onboard engines to fixed propellers. Podded units reduce vibration and noise while allowing more flexible ship design by eliminating the need for long drive shafts and rudders. Shaftline propulsion remains prevalent in many vessels due to its established reliability and simpler maintenance, making it a fundamental technology in ship propulsion systems.

Fundamentals of Podded Propulsion

Podded propulsion systems integrate electric motors within the pod units outside the ship's hull, directly driving the propellers and enhancing maneuverability and efficiency by eliminating traditional shaftlines and rudders. These systems reduce vibration and noise compared to conventional shaftline propulsion, improving onboard comfort and lowering maintenance costs due to fewer mechanical components. The fundamental design of podded propulsion allows for stepless 360-degree rotation, providing precise thrust vectoring and improved hydrodynamic performance, which is critical for dynamic positioning and advanced ship handling.

Fundamentals of Shaftline Propulsion

Shaftline propulsion systems transmit power from the engine to the propeller through a continuous shaft, offering high mechanical efficiency and reliability in marine vessels. The fundamental components include the engine, reduction gearbox, shaft, bearings, seals, and the propeller, all aligned to ensure smooth power transmission and minimal energy loss. Compared to podded propulsion, shaftline systems are often simpler to maintain and repair but may lack the maneuverability and space-saving advantages provided by podded drives.

Efficiency Comparison: Podded vs Shaftline

Podded propulsion systems offer higher efficiency in maneuverability and fuel consumption due to their ability to rotate 360 degrees, enhancing thrust vectoring and reducing hydrodynamic drag compared to traditional shaftline propulsion. Shaftline propulsion typically experiences greater mechanical losses from long transmission components and is less efficient at lower speeds or in confined environments. Studies indicate podded systems can improve overall vessel efficiency by up to 7-10%, particularly in dynamic positioning and slow cruising scenarios.

Maneuverability and Control Differences

Podded propulsion systems offer superior maneuverability compared to traditional shaftline propulsion due to their ability to rotate 360 degrees, enabling precise directional thrust and easier docking in tight spaces. Shaftline propulsion relies on fixed propellers connected to a central shaft, which limits lateral movement and requires rudders for directional control, resulting in slower response times during maneuvers. The advanced control capabilities of podded systems enhance overall vessel handling, especially in complex navigational environments and dynamic sea conditions.

Installation and Space Requirements

Podded propulsion systems require less installation space compared to traditional shaftline propulsion due to their compact, integrated design that houses the motor and propeller in a single unit mounted externally on the hull. Shaftline propulsion involves extensive internal machinery, including long shafts, bearings, and seals, demanding more engine room volume and complex alignment processes. The reduced internal space needed for podded systems allows for greater flexibility in vessel layout and can improve payload capacity.

Maintenance and Lifecycle Costs

Podded propulsion systems typically offer lower maintenance costs compared to traditional shaftline propulsion due to their modular design and easier access for repairs, which reduces downtime. Shaftline propulsion involves complex mechanical components such as long shafts, bearings, and seals that require regular inspection and replacement, increasing lifecycle expenses. Lifecycle costs of podded propulsion also benefit from improved fuel efficiency and reduced vibration, leading to less wear and extended service intervals.

Impact on Vessel Design and Layout

Podded propulsion systems enable greater design flexibility by eliminating traditional shaftlines, allowing for optimized hull shapes and increased internal space for cargo or accommodation. Shaftline propulsion requires more structural reinforcement along the engine room and shaft path, constraining vessel layout and increasing weight and maintenance access requirements. The ability of podded drives to provide 360-degree thrust vectoring improves maneuverability, influencing vessel design towards enhanced operational efficiency and safety in tight or confined waters.

Reliability and Safety Considerations

Podded propulsion systems offer enhanced reliability by integrating electric motors within the pods, reducing mechanical complexity and failure points compared to traditional shaftline propulsion. This design improves safety by allowing greater maneuverability and redundancy, as each pod operates independently, minimizing the risk of total propulsion loss. Shaftline propulsion systems, while robust and proven, involve multiple mechanical components prone to wear and potential failure, increasing maintenance demands and safety risks in comparison.

Future Trends in Marine Propulsion Choices

Future trends in marine propulsion emphasize increased adoption of podded propulsion systems due to their superior maneuverability, higher energy efficiency, and enhanced integration with electric and hybrid power sources. Shaftline propulsion remains relevant for bulk carriers and large tankers, benefiting from its established reliability and cost-effectiveness in heavy-duty operations. Advances in energy storage, automation, and eco-friendly innovations are driving manufacturers to favor podded propulsion for new builds targeting reduced emissions and compliance with stringent IMO regulations.

Azipod

Azipod propulsion offers enhanced maneuverability, higher efficiency, and reduced noise compared to traditional shaftline systems by integrating electric motors directly into podded units beneath the hull.

Fixed pitch propeller (FPP)

Fixed pitch propellers (FPP) in podded propulsion systems offer enhanced maneuverability and efficiency compared to traditional shaftline propulsion with FPP due to direct thrust alignment and reduced mechanical complexity.

Controllable pitch propeller (CPP)

Podded propulsion with Controllable Pitch Propellers (CPP) offers enhanced maneuverability, improved fuel efficiency, and reduced vibration compared to traditional Shaftline propulsion systems equipped with CPPs.

Thrust bearing

Podded propulsion systems eliminate the need for thrust bearings by integrating thrust management within the pod design, unlike shaftline propulsion which relies on traditional thrust bearings to absorb axial loads from the propeller shaft.

Electric drive motor

Podded propulsion employs electric drive motors integrated within pods for enhanced maneuverability and efficiency, whereas shaftline propulsion uses centralized electric motors connected via shafts, often resulting in higher mechanical complexity and reduced spatial flexibility.

Reduction gearbox

Podded propulsion eliminates the need for a reduction gearbox by integrating the electric motor directly with the propeller, whereas shaftline propulsion relies on a reduction gearbox to match engine speed to propeller speed efficiently.

Rudderless maneuvering

Podded propulsion systems enable superior rudderless maneuvering by providing independent thrust vectoring and enhanced directional control compared to traditional shaftline propulsion.

Integrated electric propulsion (IEP)

Integrated electric propulsion (IEP) enhances podded propulsion systems by offering superior maneuverability, improved fuel efficiency, and reduced noise compared to traditional shaftline propulsion configurations.

Stern tube sealing

Podded propulsion eliminates stern tube sealing issues by integrating the electric motor within the pod, whereas shaftline propulsion relies on complex stern tube seals to prevent water ingress along the rotating shaft.

Cavitation optimization

Podded propulsion systems optimize cavitation by reducing blade loading and improving hydrodynamic flow, resulting in lower noise and vibration compared to traditional shaftline propulsion.

Podded propulsion vs Shaftline propulsion Infographic

njnir.com

njnir.com