Anti-fouling paint uses biocides to prevent marine organisms from attaching to ship hulls, improving fuel efficiency and reducing maintenance costs. Biocide-free coatings rely on non-toxic technologies such as silicone or foul-release polymers to create a slippery surface that inhibits biofouling without harming marine life. Choosing between these options involves balancing environmental impact with effectiveness and regulatory compliance in marine engineering.

Table of Comparison

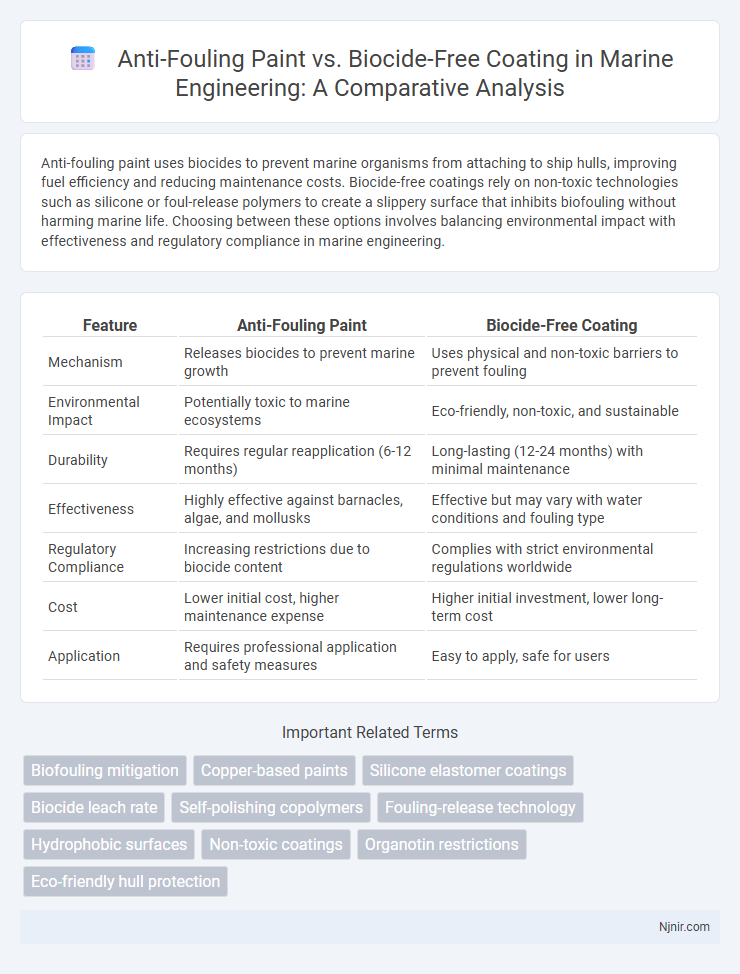

| Feature | Anti-Fouling Paint | Biocide-Free Coating |

|---|---|---|

| Mechanism | Releases biocides to prevent marine growth | Uses physical and non-toxic barriers to prevent fouling |

| Environmental Impact | Potentially toxic to marine ecosystems | Eco-friendly, non-toxic, and sustainable |

| Durability | Requires regular reapplication (6-12 months) | Long-lasting (12-24 months) with minimal maintenance |

| Effectiveness | Highly effective against barnacles, algae, and mollusks | Effective but may vary with water conditions and fouling type |

| Regulatory Compliance | Increasing restrictions due to biocide content | Complies with strict environmental regulations worldwide |

| Cost | Lower initial cost, higher maintenance expense | Higher initial investment, lower long-term cost |

| Application | Requires professional application and safety measures | Easy to apply, safe for users |

Introduction to Marine Hull Protection

Marine hull protection is critical for enhancing vessel performance and fuel efficiency, with anti-fouling paint and biocide-free coatings serving as primary solutions. Anti-fouling paints typically incorporate biocides to prevent organism growth, effectively reducing drag and corrosion but raising environmental concerns. Biocide-free coatings offer an eco-friendly alternative by utilizing physical or non-toxic barriers to inhibit fouling, promoting sustainable marine operations while maintaining hull integrity.

Understanding Anti-Fouling Paint

Anti-fouling paint incorporates biocides that actively prevent the accumulation of marine organisms such as algae, barnacles, and mussels on ship hulls, enhancing vessel performance and fuel efficiency. Biocide-free coatings rely on non-toxic, physical methods like silicone or foul-release coatings to create surfaces that inhibit organism attachment without releasing harmful chemicals into the marine environment. Understanding the composition, mechanism, and environmental impact of anti-fouling paints is crucial for selecting the appropriate solution for marine maintenance and regulatory compliance.

Overview of Biocide-Free Coatings

Biocide-free coatings prevent marine biofouling by creating physical or chemical surface properties that inhibit organism attachment without releasing harmful toxins. These coatings often utilize technologies such as silicone-based foul-release paints or microtextured surfaces to reduce drag and improve vessel efficiency. Unlike traditional anti-fouling paints containing copper or pesticides, biocide-free alternatives minimize environmental impact while maintaining effective fouling control.

Mechanisms of Fouling Prevention

Anti-fouling paint employs biocides that release toxic compounds to prevent marine organism attachment by disrupting their biological processes. In contrast, biocide-free coatings utilize non-toxic mechanisms such as slick surfaces, low surface energy, or microtexturing to physically prevent biofilm formation and organism adhesion. These physical and chemical barrier strategies reduce fouling without harmful environmental impacts associated with biocidal leaching.

Environmental Impact Comparison

Anti-fouling paint often contains biocides that release toxic substances into marine ecosystems, causing harm to non-target organisms like mollusks and fish. Biocide-free coatings minimize environmental contamination by preventing biofouling through physical or non-toxic means, reducing marine pollution and promoting biodiversity. Selecting biocide-free options aligns with sustainable marine practices and regulatory frameworks aimed at protecting aquatic habitats.

Regulatory Standards and Compliance

Anti-fouling paints containing biocides must comply with stringent regulatory standards, such as the International Maritime Organization's (IMO) Convention on the Control of Harmful Anti-fouling Systems on Ships, which restricts the use of toxic substances like tributyltin (TBT). Biocide-free coatings offer an alternative that often meets environmental regulations by avoiding harmful chemicals, reducing ecological impact and simplifying compliance with regional laws such as the European Union's Biocidal Products Regulation (BPR). Choosing biocide-free solutions supports adherence to evolving global standards aimed at minimizing marine pollution and protecting aquatic ecosystems.

Performance and Longevity Analysis

Anti-fouling paint typically outperforms biocide-free coatings in preventing marine organism buildup due to its active release of biocides that inhibit growth on hull surfaces. Biocide-free coatings rely on physical and chemical surface properties, such as low surface energy and hydrophobicity, to reduce fouling but may demonstrate shorter effective lifespans in heavily fouling environments. Longevity analyses reveal that while anti-fouling paints offer sustained protection over multiple seasons, biocide-free coatings often require more frequent reapplications to maintain comparable performance.

Application and Maintenance Requirements

Anti-fouling paint requires regular reapplication, typically every 1 to 3 years, to maintain its effectiveness against marine organisms, often involving surface cleaning and sanding before each coat. In contrast, biocide-free coatings generally offer lower maintenance needs due to their non-toxic, fouling-release properties, which allow organisms to be easily washed away during routine hull cleaning without harming the environment. Application of biocide-free coatings demands precise surface preparation and curing conditions to ensure optimal adhesion and performance, though they typically avoid the environmental risks and frequent touch-ups associated with traditional anti-fouling paints.

Cost Effectiveness and Lifecycle Assessment

Anti-fouling paint typically offers higher cost effectiveness due to its proven ability to reduce hull drag and fuel consumption, resulting in significant operational savings over the vessel's lifecycle. Biocide-free coatings present an environmentally sustainable alternative with lower ecological impact, but may involve higher upfront costs and potentially shorter maintenance intervals, influencing overall lifecycle expenses. Lifecycle assessments reveal that while anti-fouling paints extend service intervals through active biofouling prevention, biocide-free coatings demand more frequent application yet reduce toxic discharge and regulatory compliance costs.

Future Trends in Hull Coating Technologies

Future trends in hull coating technologies emphasize the shift from traditional anti-fouling paints containing biocides towards biocide-free coatings that utilize advanced materials such as silicone and fluoropolymer to reduce marine organism attachment. Innovations include the development of eco-friendly, non-toxic coatings that rely on surface texture and low surface energy to prevent fouling without harming marine ecosystems. Research in nanotechnology and biomimetic surfaces aims to enhance the durability and efficiency of these coatings, ensuring longer service intervals and improved fuel efficiency for vessels.

Biofouling mitigation

Anti-fouling paint utilizes biocides to prevent biofouling by releasing toxic substances that inhibit organism growth, while biocide-free coatings employ non-toxic, physical surface modifications to mitigate biofouling without environmental harm.

Copper-based paints

Copper-based anti-fouling paints effectively prevent marine biofouling by releasing biocides, whereas biocide-free coatings rely on physical properties to deter organism attachment without toxic substances.

Silicone elastomer coatings

Silicone elastomer coatings offer superior foul-release performance compared to traditional anti-fouling paint by providing a biocide-free, environmentally friendly alternative that reduces marine organism adhesion through low surface energy and elastic properties.

Biocide leach rate

Anti-fouling paint typically exhibits a higher biocide leach rate compared to biocide-free coatings, which release no toxic substances and minimize environmental impact.

Self-polishing copolymers

Self-polishing copolymer anti-fouling paints release controlled biocides to prevent marine growth effectively while biocide-free coatings rely on physical surface properties to inhibit fouling without chemical leaching.

Fouling-release technology

Fouling-release technology in biocide-free coatings offers an eco-friendly alternative to traditional anti-fouling paints by preventing marine organism attachment through ultra-smooth, low-adhesion surfaces rather than toxic biocides.

Hydrophobic surfaces

Hydrophobic surfaces in anti-fouling paint provide superior water repellency and reduced biofouling compared to biocide-free coatings, enhancing marine vessel performance and durability.

Non-toxic coatings

Non-toxic coatings like biocide-free options offer environmentally safe anti-fouling protection by preventing marine organism growth without harmful chemicals.

Organotin restrictions

Anti-fouling paints containing organotin compounds face strict regulatory restrictions due to environmental toxicity, leading to increased adoption of biocide-free coatings that provide eco-friendly marine vessel protection without harmful organotin biocides.

Eco-friendly hull protection

Biocide-free coatings provide eco-friendly hull protection by preventing biofouling without releasing harmful toxins, unlike traditional anti-fouling paints that rely on biocides.

anti-fouling paint vs biocide-free coating Infographic

njnir.com

njnir.com