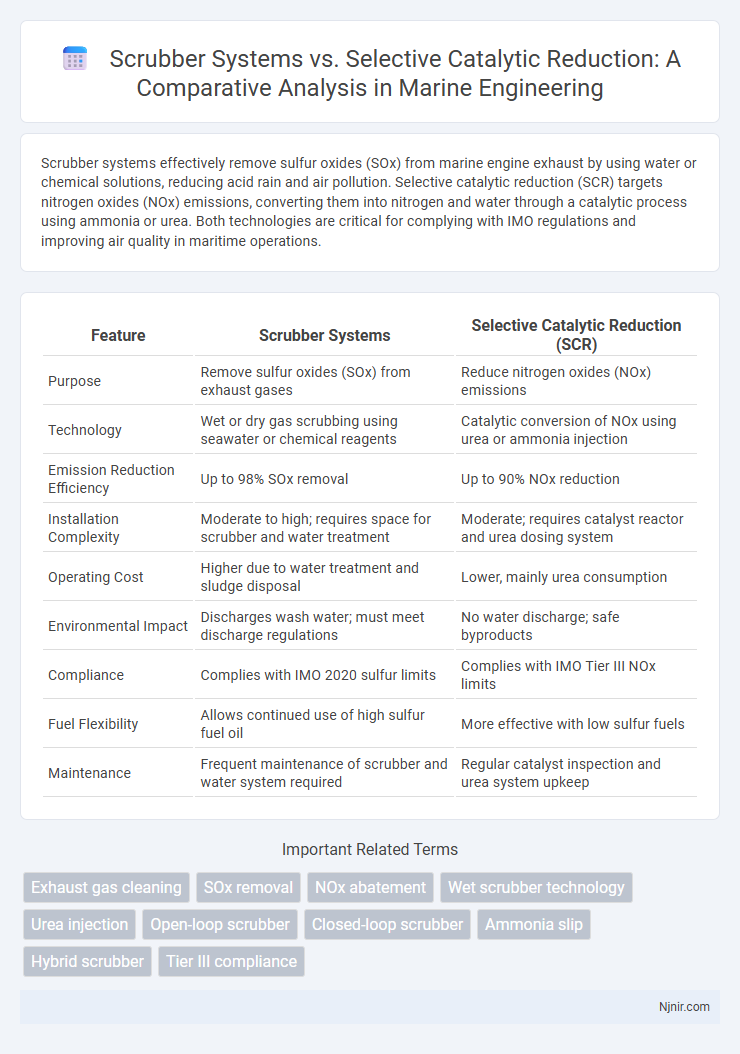

Scrubber systems effectively remove sulfur oxides (SOx) from marine engine exhaust by using water or chemical solutions, reducing acid rain and air pollution. Selective catalytic reduction (SCR) targets nitrogen oxides (NOx) emissions, converting them into nitrogen and water through a catalytic process using ammonia or urea. Both technologies are critical for complying with IMO regulations and improving air quality in maritime operations.

Table of Comparison

| Feature | Scrubber Systems | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Remove sulfur oxides (SOx) from exhaust gases | Reduce nitrogen oxides (NOx) emissions |

| Technology | Wet or dry gas scrubbing using seawater or chemical reagents | Catalytic conversion of NOx using urea or ammonia injection |

| Emission Reduction Efficiency | Up to 98% SOx removal | Up to 90% NOx reduction |

| Installation Complexity | Moderate to high; requires space for scrubber and water treatment | Moderate; requires catalyst reactor and urea dosing system |

| Operating Cost | Higher due to water treatment and sludge disposal | Lower, mainly urea consumption |

| Environmental Impact | Discharges wash water; must meet discharge regulations | No water discharge; safe byproducts |

| Compliance | Complies with IMO 2020 sulfur limits | Complies with IMO Tier III NOx limits |

| Fuel Flexibility | Allows continued use of high sulfur fuel oil | More effective with low sulfur fuels |

| Maintenance | Frequent maintenance of scrubber and water system required | Regular catalyst inspection and urea system upkeep |

Introduction to Marine Emission Control Technologies

Scrubber systems and Selective Catalytic Reduction (SCR) are advanced marine emission control technologies designed to reduce harmful exhaust pollutants from ship engines. Scrubber systems primarily remove sulfur oxides (SOx) by washing exhaust gases with seawater or freshwater, effectively enabling compliance with stringent sulfur emission limits set by the IMO 2020 regulation. SCR technology targets nitrogen oxides (NOx) by injecting a reductant such as ammonia or urea into the exhaust stream, converting NOx into harmless nitrogen and water, thus meeting Tier III emission standards in Emission Control Areas (ECAs).

Overview of Scrubber Systems in Shipping

Scrubber systems in shipping are exhaust gas cleaning technologies designed to remove sulfur oxides (SOx) from the ship's engine and boiler emissions, helping vessels comply with IMO sulfur emission limits. These systems typically use seawater or freshwater to neutralize and wash out pollutants before releasing cleaned gases into the atmosphere, reducing the environmental impact of marine operations. Scrubbers offer an alternative to using low-sulfur fuel, enabling ships to continue using higher sulfur fuels while meeting regulatory requirements.

Selective Catalytic Reduction (SCR): Fundamentals and Applications

Selective Catalytic Reduction (SCR) is an advanced emissions control technology that reduces nitrogen oxides (NOx) by injecting a reductant, typically ammonia or urea, into the exhaust stream, followed by a catalytic reaction that converts NOx into nitrogen and water. SCR systems are widely applied in diesel engines, power plants, and industrial processes to meet stringent environmental regulations such as Euro VI and EPA Tier 4 standards. Key benefits of SCR include high NOx reduction efficiency, fuel economy improvement, and compatibility with various fuel types, making it a critical solution for sustainable air quality management.

Regulatory Drivers: IMO and MARPOL Requirements

Scrubber systems and Selective Catalytic Reduction (SCR) technologies meet stringent IMO and MARPOL regulations aimed at reducing sulfur oxides (SOx) and nitrogen oxides (NOx) emissions from marine vessels. IMO 2020 Sulfur Cap mandates a global sulfur limit of 0.5% m/m in fuel oil, driving the installation of exhaust gas cleaning systems like scrubbers to comply without switching to expensive low-sulfur fuels. MARPOL Annex VI further enforces Tier III NOx emission limits in designated Emission Control Areas (ECAs), encouraging adoption of SCR systems that convert NOx into harmless nitrogen and water vapor to meet these precise environmental standards.

Operational Mechanisms: Scrubbers vs. SCR Systems

Scrubber systems operate by removing sulfur oxides (SOx) from exhaust gases through a chemical absorption process involving seawater or alkaline substances, which neutralize harmful emissions before release. Selective Catalytic Reduction (SCR) systems reduce nitrogen oxides (NOx) by injecting a urea-based reductant into the exhaust stream, converting NOx into nitrogen and water through a catalytic reaction. Both systems are essential for meeting maritime emission regulations, with scrubbers targeting SOx and SCR focused on NOx reduction via distinct operational mechanisms.

Installation and Retrofit Considerations

Scrubber systems require extensive modifications to exhaust stacks and seawater or chemical handling infrastructure, often making retrofit installation complex and space-intensive. Selective catalytic reduction (SCR) units generally have a more compact footprint but necessitate integration with existing exhaust gas systems and supply of urea-based reductants, which can present logistical challenges. Both technologies demand careful engineering assessment to address vessel-specific constraints, system compatibility, and downtime minimization during retrofit implementation.

Environmental Impact and Emission Reduction Efficiency

Scrubber systems effectively reduce sulfur oxide (SOx) emissions by using chemical reactions to remove pollutants from exhaust gases, significantly lowering acid rain contributors. Selective catalytic reduction (SCR) systems target nitrogen oxides (NOx), converting them into harmless nitrogen and water through ammonia-based catalysis, achieving reduction efficiencies of up to 90%. While scrubbers primarily address SOx and particulate matter, SCR systems specialize in NOx control, making both technologies complementary for comprehensive marine emission compliance and improved air quality.

Cost Analysis: Capital, Operating, and Maintenance Expenses

Scrubber systems typically involve higher initial capital costs due to complex hardware installation and retrofitting requirements, while selective catalytic reduction (SCR) systems may have lower upfront expenses but require costly catalysts. Operating costs for scrubbers include significant consumables like chemicals and water, whereas SCR systems incur expenses mainly from catalyst replacement and ammonia consumption. Maintenance for scrubbers is more intensive due to corrosion and scaling issues, while SCR maintenance focuses on catalyst inspection and pollution control system calibration.

Technical Challenges and Reliability Issues

Scrubber systems face technical challenges such as high operational costs, complex maintenance due to handling corrosive scrubber liquids, and issues with clogging and scaling that compromise system performance. Selective catalytic reduction (SCR) systems encounter reliability issues related to catalyst poisoning, ammonia slip, and sensitivity to fluctuating exhaust temperatures, which affect NOx reduction efficiency. Both technologies require rigorous monitoring and maintenance protocols to ensure consistent emission control and operational stability in maritime and industrial applications.

Future Outlook: Innovations and Industry Trends

Scrubber systems and Selective Catalytic Reduction (SCR) technologies are evolving rapidly to meet stricter emission regulations, with innovations focusing on enhanced efficiency and reduced operational costs. Emerging trends include integrating hybrid scrubber-SCR units and utilizing advanced catalysts that improve nitrogen oxide (NOx) reduction rates while minimizing energy consumption. The maritime and industrial sectors are investing heavily in digital monitoring and automated controls, driving future adoption of smarter, more scalable emission control solutions.

Exhaust gas cleaning

Scrubber systems remove sulfur oxides and particulate matter from exhaust gases through chemical washing, while Selective Catalytic Reduction (SCR) specifically targets nitrogen oxides by converting them into nitrogen and water using a catalyst and ammonia or urea injection.

SOx removal

Scrubber systems achieve up to 98% SOx removal by using alkaline washes to neutralize sulfur oxides in exhaust gases, whereas Selective Catalytic Reduction primarily targets NOx reduction and is less effective for SOx removal.

NOx abatement

Selective catalytic reduction (SCR) systems achieve up to 90% NOx abatement efficiency by converting nitrogen oxides into nitrogen and water, while scrubber systems primarily target sulfur dioxide and are less effective for NOx removal.

Wet scrubber technology

Wet scrubber technology in scrubber systems effectively removes sulfur dioxide (SO2) from ship exhaust gases by using liquid absorption, offering a reliable alternative to Selective Catalytic Reduction (SCR) systems which primarily reduce nitrogen oxides (NOx) through catalyst-driven chemical reactions.

Urea injection

Selective catalytic reduction (SCR) uses urea injection to convert nitrogen oxides (NOx) into nitrogen and water, while scrubber systems primarily remove sulfur oxides (SOx) through chemical washing without urea involvement.

Open-loop scrubber

Open-loop scrubber systems remove sulfur oxides from ship exhaust by using seawater for neutralization, offering simpler installation and lower operational costs compared to the more complex and catalyst-dependent Selective Catalytic Reduction systems that reduce nitrogen oxides.

Closed-loop scrubber

Closed-loop scrubber systems efficiently remove sulfur oxides from marine engine exhaust by recycling wash water through treatment units, offering an environmentally sustainable alternative to Selective Catalytic Reduction which primarily targets nitrogen oxide emissions.

Ammonia slip

Selective catalytic reduction systems reduce NOx emissions efficiently but can cause ammonia slip, whereas scrubber systems primarily target SOx removal without ammonia slip concerns.

Hybrid scrubber

Hybrid scrubber systems combine the advantages of scrubber systems and Selective Catalytic Reduction (SCR) to optimize sulfur oxide and nitrogen oxide emissions control in marine and industrial applications.

Tier III compliance

Selective catalytic reduction systems achieve Tier III compliance by significantly reducing NOx emissions, whereas scrubber systems primarily target SOx removal without directly addressing NOx limits.

Scrubber systems vs Selective catalytic reduction Infographic

njnir.com

njnir.com