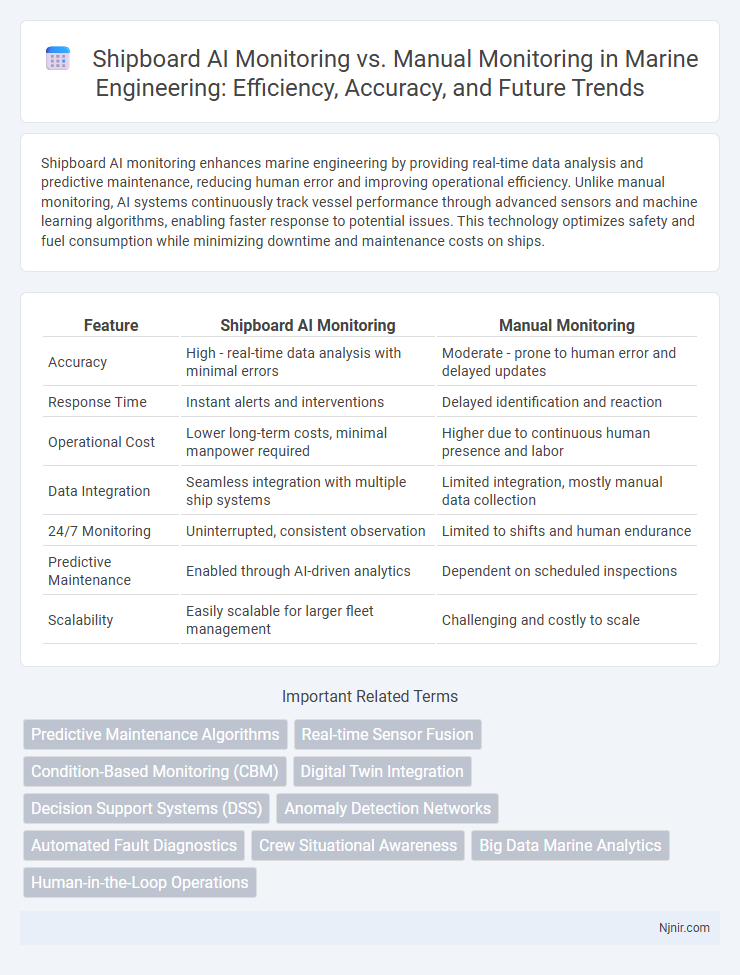

Shipboard AI monitoring enhances marine engineering by providing real-time data analysis and predictive maintenance, reducing human error and improving operational efficiency. Unlike manual monitoring, AI systems continuously track vessel performance through advanced sensors and machine learning algorithms, enabling faster response to potential issues. This technology optimizes safety and fuel consumption while minimizing downtime and maintenance costs on ships.

Table of Comparison

| Feature | Shipboard AI Monitoring | Manual Monitoring |

|---|---|---|

| Accuracy | High - real-time data analysis with minimal errors | Moderate - prone to human error and delayed updates |

| Response Time | Instant alerts and interventions | Delayed identification and reaction |

| Operational Cost | Lower long-term costs, minimal manpower required | Higher due to continuous human presence and labor |

| Data Integration | Seamless integration with multiple ship systems | Limited integration, mostly manual data collection |

| 24/7 Monitoring | Uninterrupted, consistent observation | Limited to shifts and human endurance |

| Predictive Maintenance | Enabled through AI-driven analytics | Dependent on scheduled inspections |

| Scalability | Easily scalable for larger fleet management | Challenging and costly to scale |

Overview of Shipboard Monitoring Systems

Shipboard AI monitoring systems leverage real-time data analytics, machine learning algorithms, and sensor fusion to enhance vessel performance, safety, and predictive maintenance compared to traditional manual monitoring. These systems provide continuous, automated surveillance of engine conditions, navigation parameters, and environmental factors, reducing human error and response time. Manual monitoring relies heavily on crew observation and periodic checks, which may lack the precision and immediacy facilitated by AI-driven technologies integrated into modern shipboard systems.

Evolution from Manual to AI Monitoring in Marine Engineering

Shipboard AI monitoring has revolutionized marine engineering by significantly enhancing real-time data analysis and predictive maintenance compared to traditional manual monitoring methods. Manual monitoring relied on human observation and periodic data logging, often resulting in slower response times and increased risk of human error. The evolution to AI-driven systems enables continuous, accurate monitoring of engine performance, fuel consumption, and safety parameters, improving operational efficiency and reducing downtime.

Key Technologies Driving AI Shipboard Monitoring

Shipboard AI monitoring leverages advanced sensors, machine learning algorithms, and real-time data analytics to enhance situational awareness and predictive maintenance, significantly outperforming manual monitoring methods prone to human error and delayed response. Key technologies driving AI shipboard monitoring include convolutional neural networks for image recognition, IoT sensors for continuous data collection, and edge computing for immediate onboard data processing. These innovations enable proactive decision-making, improved safety, and operational efficiency in modern maritime operations.

Accuracy and Reliability: AI vs Manual Monitoring

Shipboard AI monitoring offers superior accuracy by continuously analyzing vast amounts of sensor data in real-time, reducing human errors and improving detection of anomalies. Manual monitoring relies heavily on human vigilance and experience, which can lead to inconsistencies and delayed responses during critical situations. AI systems provide enhanced reliability by ensuring constant surveillance without fatigue, leading to more precise and timely decision-making compared to manual methods.

Data Collection and Real-Time Analysis Capabilities

Shipboard AI monitoring systems collect vast amounts of sensor data continuously, enabling real-time analysis of vessel performance, engine conditions, and navigational safety with higher accuracy than manual monitoring. These AI solutions utilize machine learning algorithms to detect anomalies and predict maintenance needs instantly, reducing the risk of human error and delays associated with manual data logging. Manual monitoring relies on periodic checks and human interpretation, which often results in slower data processing and limited capacity for immediate decision-making during critical events.

Human Error Risks Versus AI Algorithm Limitations

Shipboard AI monitoring reduces human error risks by continuously analyzing data with advanced algorithms, enabling early detection of anomalies and operational inefficiencies. However, AI algorithm limitations include potential misinterpretation of complex maritime scenarios and reliance on quality sensor inputs, which could lead to false alarms or undetected issues. Manual monitoring is prone to fatigue, distractions, and inconsistent judgment, increasing the risk of oversight but benefits from human intuition and contextual decision-making in ambiguous situations.

Operational Efficiency and Response Times

Shipboard AI monitoring enhances operational efficiency by continuously analyzing vast amounts of sensor data in real-time, reducing human error and enabling predictive maintenance that minimizes downtime. Manual monitoring relies heavily on crew vigilance, which can be slower and less consistent, often delaying detection of anomalies and emergency situations. AI-driven systems accelerate response times by instantly identifying risks and automatically alerting operators, ensuring faster decision-making compared to traditional manual methods.

Safety Enhancements through AI Monitoring Systems

Shipboard AI monitoring systems provide real-time data analysis and predictive insights that significantly enhance maritime safety by detecting potential hazards before they escalate. These systems continuously track vessel performance, environmental conditions, and crew activities, reducing human error and enabling faster response times compared to manual monitoring. Implementing AI-driven monitoring leads to improved accident prevention, optimized navigation, and overall safer ship operations.

Training and Skill Requirements for Crew

Shipboard AI monitoring requires crew members to acquire advanced technical skills in AI system operation, data interpretation, and cybersecurity, significantly reducing human error and enhancing safety. Manual monitoring relies heavily on traditional maritime skills, demanding extensive experience and constant vigilance to identify and respond to anomalies effectively. Training programs for AI systems emphasize continuous learning and adaptation, while manual monitoring requires frequent refresher courses to maintain situational awareness and decision-making proficiency.

Cost-Benefit Analysis: AI Monitoring Versus Manual Procedures

Shipboard AI monitoring significantly reduces operational costs by automating data collection and analysis, minimizing manpower requirements and human error. Manual monitoring incurs higher labor expenses and risks inconsistent data quality due to fatigue or oversight, impacting maintenance and safety outcomes. The cost-benefit analysis favors AI monitoring through improved efficiency, real-time anomaly detection, and long-term savings in crew deployment and accident prevention.

Predictive Maintenance Algorithms

Shipboard AI monitoring leverages advanced predictive maintenance algorithms to analyze real-time sensor data, enabling early fault detection and reducing downtime compared to traditional manual monitoring methods.

Real-time Sensor Fusion

Shipboard AI monitoring enables real-time sensor fusion by integrating data from multiple sensors instantly, outperforming manual monitoring's slower, less accurate data analysis and improving situational awareness and decision-making on vessels.

Condition-Based Monitoring (CBM)

Shipboard AI monitoring enhances Condition-Based Monitoring (CBM) by providing continuous real-time data analysis for early fault detection and predictive maintenance, surpassing the intermittent and subjective nature of manual monitoring.

Digital Twin Integration

Shipboard AI monitoring enhances manual monitoring by integrating Digital Twin technology, enabling real-time simulation, predictive analytics, and proactive maintenance to optimize vessel performance and safety.

Decision Support Systems (DSS)

Shipboard AI monitoring enhances Decision Support Systems (DSS) by providing real-time data analysis and predictive insights, significantly improving accuracy and response times compared to traditional manual monitoring methods.

Anomaly Detection Networks

Shipboard AI monitoring leverages advanced anomaly detection networks to identify irregular vessel behaviors in real-time with higher accuracy and speed compared to manual monitoring methods.

Automated Fault Diagnostics

Automated fault diagnostics in shipboard AI monitoring enhances real-time detection accuracy and reduces human error compared to traditional manual monitoring methods.

Crew Situational Awareness

Shipboard AI monitoring enhances crew situational awareness by providing real-time data analysis and predictive insights, reducing human error inherent in manual monitoring.

Big Data Marine Analytics

Shipboard AI monitoring leverages Big Data Marine Analytics to provide real-time, precise insights and predictive maintenance, significantly outperforming manual monitoring in efficiency and accuracy.

Human-in-the-Loop Operations

Shipboard AI monitoring enhances efficiency by integrating real-time data analysis with human-in-the-loop decision-making, reducing errors compared to manual monitoring systems.

Shipboard AI monitoring vs Manual monitoring Infographic

njnir.com

njnir.com