Shaft generators harness mechanical energy from the ship's main engine shaft to produce electricity, offering fuel savings and reduced emissions compared to auxiliary generators, which rely on separate diesel engines for power generation. Auxiliary generators provide essential backup power during main engine shutdowns and enable electric supply in port or low-speed operations, ensuring continuous vessel operation. Choosing between shaft and auxiliary generators depends on operational needs, fuel efficiency goals, and maintenance considerations within marine engineering.

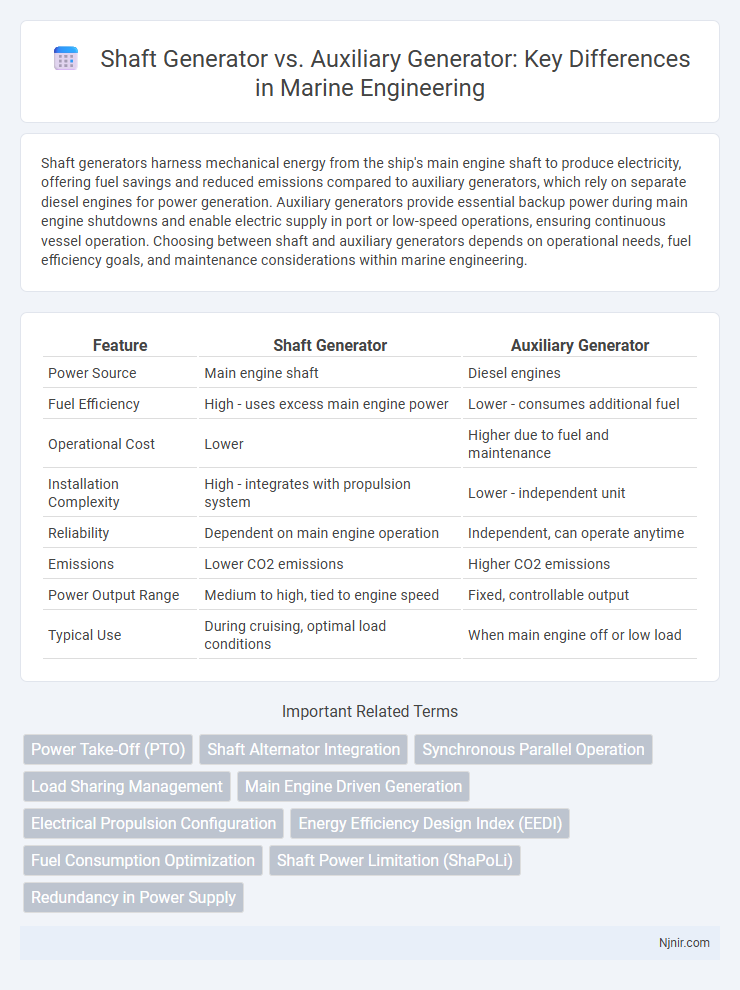

Table of Comparison

| Feature | Shaft Generator | Auxiliary Generator |

|---|---|---|

| Power Source | Main engine shaft | Diesel engines |

| Fuel Efficiency | High - uses excess main engine power | Lower - consumes additional fuel |

| Operational Cost | Lower | Higher due to fuel and maintenance |

| Installation Complexity | High - integrates with propulsion system | Lower - independent unit |

| Reliability | Dependent on main engine operation | Independent, can operate anytime |

| Emissions | Lower CO2 emissions | Higher CO2 emissions |

| Power Output Range | Medium to high, tied to engine speed | Fixed, controllable output |

| Typical Use | During cruising, optimal load conditions | When main engine off or low load |

Introduction to Shaft and Auxiliary Generators

Shaft generators are integrated into the main engine shaft of a ship, converting mechanical energy directly into electrical power, ensuring efficient energy use during propulsion. Auxiliary generators are independent units powered by separate diesel engines, providing electrical power when the main engine is not running or when additional power is needed. Both generators play crucial roles in maritime electrical systems, balancing energy production and operational flexibility.

Key Differences Between Shaft and Auxiliary Generators

Shaft generators are mechanically driven by the main engine or shaft, converting mechanical energy into electrical power primarily during vessel operation, while auxiliary generators are independent engines designed to supply power when the main engine is off or during peak loads. Shaft generators offer fuel efficiency and reduced emissions by utilizing engine rotation, whereas auxiliary generators provide flexibility and backup power reliability. Key differences include power source dependency, operational usage, and environmental impact, with shaft generators being integral to primary propulsion systems and auxiliary generators serving as supplementary energy sources.

Working Principle of Shaft Generators

Shaft generators operate by converting mechanical energy from the ship's main engine shaft rotation into electrical energy, providing power while the engine runs. Unlike auxiliary generators, which use separate diesel engines to generate electricity independently, shaft generators rely directly on the propulsion system's motion. This integration enhances fuel efficiency by utilizing the engine's existing kinetic energy, reducing the need for additional fuel consumption during operation.

Operation of Auxiliary Generators

Auxiliary generators operate independently from the ship's main propulsion system, providing essential electrical power during low-speed maneuvers, port stays, or emergencies when the shaft generator is inactive. They use diesel engines to generate electricity, ensuring continuous power supply for onboard systems such as lighting, navigation, and communication equipment. Auxiliary generators complement shaft generators by maintaining operational reliability and energy availability under varied vessel operating conditions.

Advantages of Shaft Generators in Marine Vessels

Shaft generators in marine vessels offer significant fuel savings by utilizing the ship's main engine to produce electrical power, reducing reliance on auxiliary engines. These generators provide higher overall efficiency, lower emissions, and decreased maintenance costs compared to auxiliary generators. Enhanced operational reliability and reduced noise levels also contribute to their growing preference in modern marine propulsion systems.

Benefits of Using Auxiliary Generators

Auxiliary generators provide reliable power backup for critical shipboard systems when the main propulsion shaft is inactive or insufficient, ensuring continuous electricity supply during port operations or emergencies. These generators offer flexibility by operating independently from the shaft generator, enabling maintenance or repairs without disrupting onboard power needs. Their ability to support varied loads and start quickly enhances overall vessel safety and operational efficiency.

Energy Efficiency Comparison: Shaft vs Auxiliary Generators

Shaft generators harness mechanical energy from the main engine, converting it directly into electrical power, resulting in higher energy efficiency and reduced fuel consumption compared to auxiliary generators. Auxiliary generators rely on separate engines, leading to additional fuel usage and increased emissions during electricity production. Optimizing the use of shaft generators significantly lowers operational costs and minimizes environmental impact in marine and industrial applications.

Installation and Maintenance Requirements

Shaft generators are installed directly on the main engine shaft, offering compact integration but requiring precise alignment and occasional shaft downtime for maintenance. Auxiliary generators, mounted independently on the engine room foundation, allow easier access and routine service without impacting the main propulsion system. Maintenance of shaft generators involves monitoring bearing lubrication and cooling systems, whereas auxiliary generators require regular inspection of electrical connections and fuel supply systems.

Impact on Vessel Emissions and Environmental Compliance

Shaft generators reduce vessel emissions by converting mechanical energy from the main engine into electrical power, thereby lowering fuel consumption and greenhouse gas output compared to auxiliary generators, which rely on diesel engines emitting higher levels of NOx and SOx. Utilizing shaft generators assists vessels in meeting stringent environmental compliance standards such as IMO Tier III regulations and the Energy Efficiency Design Index (EEDI). Auxiliary generators remain essential for supplemental power but contribute to increased environmental impact due to higher pollutant emissions and fuel usage.

Cost Considerations and Operational Economics

Shaft generators, integrated with the main engine, offer lower fuel consumption and operational costs by generating electricity during propulsion, reducing reliance on auxiliary generators. Auxiliary generators incur higher fuel and maintenance expenses due to constant use, especially during idle or low speeds when the shaft generator is ineffective. Evaluating initial investment versus long-term savings highlights that shaft generators are cost-efficient for vessels with steady engine operation, while auxiliary generators provide flexibility but at higher operational expenditure.

Power Take-Off (PTO)

Shaft generators utilize the ship's main engine Power Take-Off (PTO) to convert mechanical energy directly into electrical power, offering higher efficiency than auxiliary generators, which rely on separate engines for power generation.

Shaft Alternator Integration

Shaft generators integrate directly with a ship's propulsion shaft to efficiently convert mechanical energy into electrical power, contrasting with auxiliary generators that operate independently to provide backup or additional power.

Synchronous Parallel Operation

Shaft generators and auxiliary generators both support synchronous parallel operation by maintaining synchronized voltage, frequency, and phase to ensure stable power distribution on vessels.

Load Sharing Management

Shaft generators optimize load sharing by directly converting engine torque into electrical power for ship systems, while auxiliary generators manage variable electrical loads independently during low engine speeds or peak demand periods.

Main Engine Driven Generation

Main engine driven shaft generators provide efficient electrical power by converting mechanical energy directly from the ship's propeller shaft, contrasting with auxiliary generators that rely on separate diesel engines for electric power generation during main engine downtime or peak load demands.

Electrical Propulsion Configuration

Shaft generators in electrical propulsion configurations convert mechanical energy from the main engine into electrical power, improving fuel efficiency, while auxiliary generators provide backup electrical power independent of the propulsion system for shipboard electrical loads.

Energy Efficiency Design Index (EEDI)

Shaft generators directly convert engine power into electrical energy reducing fuel consumption and improving Energy Efficiency Design Index (EEDI) compared to auxiliary generators that rely on separate engines and increase overall emissions.

Fuel Consumption Optimization

Shaft generators optimize fuel consumption by converting engine power into electrical energy during operation, reducing reliance on auxiliary generators which consume additional fuel by running separate engines.

Shaft Power Limitation (ShaPoLi)

Shaft generators have shaft power limitations (ShaPoLi) that restrict their maximum output based on the engine's available mechanical power, whereas auxiliary generators operate independently on electrical power sources without such mechanical constraints.

Redundancy in Power Supply

Shaft generators provide primary power during vessel propulsion, while auxiliary generators offer crucial redundancy by supplying backup power to maintain uninterrupted electrical systems when the shaft generator is offline.

Shaft Generator vs Auxiliary Generator Infographic

njnir.com

njnir.com