Dry docking inspection allows for a comprehensive assessment of a vessel's hull, propellers, and sea valves by removing it from the water, enabling direct visual access and physical maintenance. Underwater inspection uses divers or remotely operated vehicles (ROVs) to examine submerged parts without removing the ship from service, providing real-time monitoring of hull integrity and potential damage. Each method offers unique advantages depending on maintenance urgency, cost considerations, and inspection depth required.

Table of Comparison

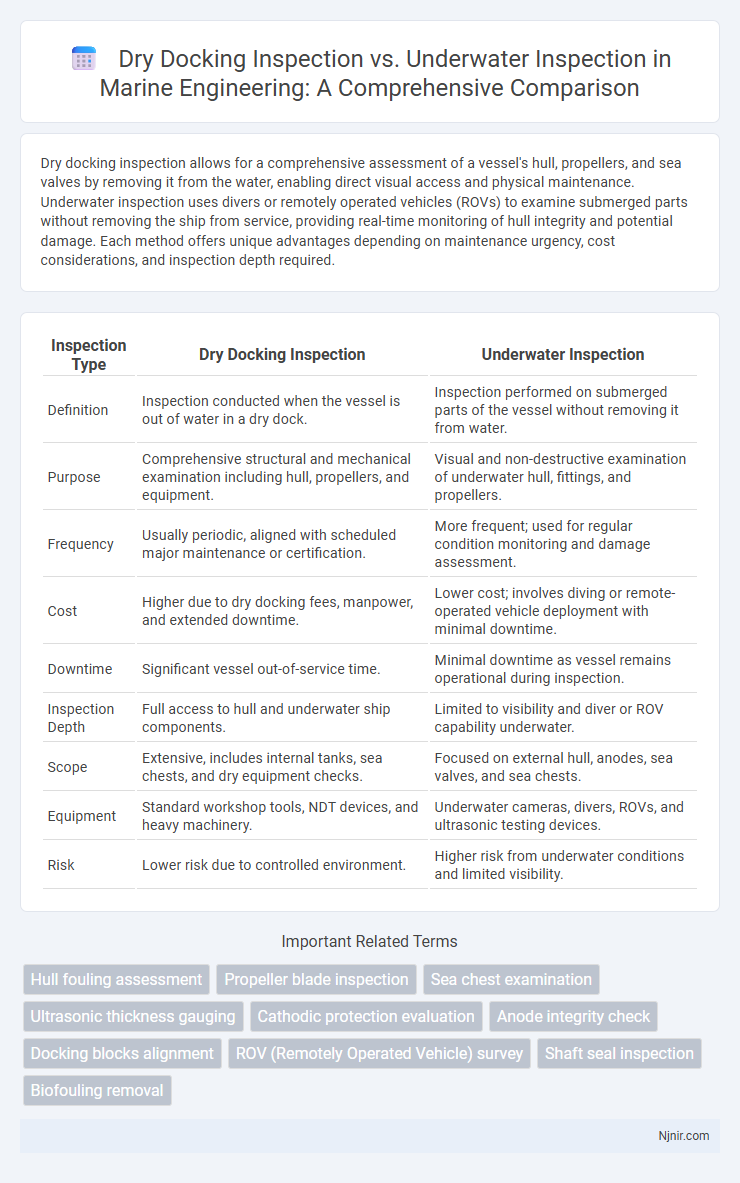

| Inspection Type | Dry Docking Inspection | Underwater Inspection |

|---|---|---|

| Definition | Inspection conducted when the vessel is out of water in a dry dock. | Inspection performed on submerged parts of the vessel without removing it from water. |

| Purpose | Comprehensive structural and mechanical examination including hull, propellers, and equipment. | Visual and non-destructive examination of underwater hull, fittings, and propellers. |

| Frequency | Usually periodic, aligned with scheduled major maintenance or certification. | More frequent; used for regular condition monitoring and damage assessment. |

| Cost | Higher due to dry docking fees, manpower, and extended downtime. | Lower cost; involves diving or remote-operated vehicle deployment with minimal downtime. |

| Downtime | Significant vessel out-of-service time. | Minimal downtime as vessel remains operational during inspection. |

| Inspection Depth | Full access to hull and underwater ship components. | Limited to visibility and diver or ROV capability underwater. |

| Scope | Extensive, includes internal tanks, sea chests, and dry equipment checks. | Focused on external hull, anodes, sea valves, and sea chests. |

| Equipment | Standard workshop tools, NDT devices, and heavy machinery. | Underwater cameras, divers, ROVs, and ultrasonic testing devices. |

| Risk | Lower risk due to controlled environment. | Higher risk from underwater conditions and limited visibility. |

Introduction to Ship Inspection Methods

Dry docking inspection involves taking a vessel out of the water to conduct thorough examinations of the hull, propellers, rudders, and other submerged structures, allowing for detailed visual and non-destructive testing. Underwater inspection employs divers or remotely operated vehicles (ROVs) to assess the ship's underwater condition without removing it from the water, facilitating quicker, cost-effective evaluations of hull integrity, marine growth, and damage. Both methods are critical in maritime maintenance, ensuring regulatory compliance and optimizing vessel performance through targeted inspections.

Overview of Dry Docking Inspection

Dry docking inspection involves the ship being brought to a specialized facility where it is suspended out of water for a thorough examination of the hull, propellers, rudders, and underwater structures. This process allows for comprehensive maintenance, repair, and coating applications that cannot be performed during operations. Dry docking is essential for ensuring vessel safety, compliance with maritime regulations, and prolonging the ship's structural integrity.

Understanding Underwater Inspection

Underwater inspection involves the detailed examination of a vessel's hull, propellers, and other submerged components without removing it from the water, using specialized divers or remotely operated vehicles (ROVs). This method enables timely detection of corrosion, biofouling, cracks, and structural damages to ensure vessel safety and compliance with maritime regulations. Unlike dry docking inspection, underwater inspection reduces downtime and operational costs by avoiding the need to take the ship out of service.

Key Differences Between Dry Docking and Underwater Inspection

Dry docking inspection involves physically taking a vessel out of the water to allow thorough examination and maintenance of the hull and underwater structures, enabling tasks like painting, cleaning, and repair that cannot be performed underwater. Underwater inspection uses divers or remotely operated vehicles (ROVs) to assess the ship's exterior and subsea components without removing it from the water, focusing primarily on visual and non-intrusive evaluations. The key differences lie in accessibility, scope of maintenance, cost, and downtime, with dry docking requiring significant vessel downtime and higher expenses but permitting extensive repairs, while underwater inspection offers faster, less costly assessments but limited intervention capabilities.

Advantages of Dry Docking Inspection

Dry docking inspection offers comprehensive access to all parts of a vessel's hull for thorough cleaning, repairs, and detailed structural assessments that underwater inspection cannot fully achieve. This method enables safe evaluation of critical components such as propellers, rudders, and hull coatings, ensuring accurate detection and rectification of corrosion or damage. Dry docking also facilitates compliance with stringent regulatory standards, extending vessel lifespan through precise maintenance and improvements.

Benefits of Underwater Inspection

Underwater inspection offers significant benefits by enabling real-time assessment of a vessel's hull, propellers, and underwater structures without the need to remove the ship from water, thus minimizing operational downtime and reducing costs. This method allows for early detection of corrosion, fouling, and structural damage, which helps maintain vessel safety and compliance with maritime regulations. Underwater inspections also facilitate immediate maintenance decisions, enhancing overall fleet efficiency and extending the service life of marine assets.

Common Challenges in Both Inspection Methods

Dry docking inspection and underwater inspection both encounter challenges such as limited access to complex or confined areas, which hinders thorough examination of hull and structural components. Environmental factors like water clarity, currents, and weather conditions pose significant obstacles during underwater inspections, while the downtime and logistical demands of dry docking increase operational costs. Corrosion, biofouling, and structural fatigue detection remain critical issues requiring specialized equipment and skilled personnel for accurate assessment in both methods.

Cost Comparison: Dry Docking vs Underwater Inspection

Dry docking inspection typically incurs higher costs due to the need for vessel immobilization, extensive labor, and facility fees, often ranging from tens to hundreds of thousands of dollars depending on ship size. Underwater inspection offers a cost-effective alternative by eliminating dry dock fees and reducing operational downtime, with expenses primarily related to specialized divers or remotely operated vehicles (ROVs). The choice between dry docking and underwater inspection hinges on balancing cost savings against inspection scope, with underwater methods favored for routine checks and dry docking reserved for comprehensive maintenance.

Suitability for Different Vessel Types and Conditions

Dry docking inspection is ideal for large or complex vessels requiring comprehensive structural checks, repairs, and maintenance inaccessible while afloat, particularly suited for cargo ships, tankers, and passenger vessels during scheduled maintenance. Underwater inspection offers a cost-effective, non-intrusive alternative for smaller vessels, such as fishing boats and recreational yachts, or situations demanding frequent monitoring without removing the ship from water. Vessel type, operational schedule, and condition severity determine the choice between dry docking's thorough assessment and underwater inspection's flexibility and rapid deployment.

Future Trends in Marine Vessel Inspection

Future trends in marine vessel inspection emphasize advanced underwater inspection technologies such as robotics, autonomous underwater vehicles (AUVs), and AI-driven imaging systems that enhance precision and reduce the need for dry docking. Innovations in sensor technology and real-time data analytics enable continuous hull condition monitoring, minimizing operational downtime and maintenance costs associated with traditional dry docking inspection. Integration of digital twins and predictive maintenance frameworks leverages underwater inspection data to optimize vessel lifespan and safety standards in the maritime industry.

Hull fouling assessment

Hull fouling assessment during dry docking inspection provides a comprehensive, detailed evaluation of marine growth and structural integrity that underwater inspection may partially miss due to visibility and access limitations.

Propeller blade inspection

Dry docking inspection provides a comprehensive and detailed assessment of propeller blades including dimensional accuracy and surface integrity, while underwater inspection offers a cost-effective, real-time evaluation with visual detection of major damages without requiring vessel removal.

Sea chest examination

Sea chest examination during dry docking inspection offers detailed visual access and maintenance opportunities, whereas underwater inspection relies on remote imaging techniques providing limited assessment of sea chest conditions.

Ultrasonic thickness gauging

Ultrasonic thickness gauging during dry docking inspection provides precise hull measurements without water interference, whereas underwater inspection challenges accuracy due to water-coupling and visibility factors.

Cathodic protection evaluation

Dry docking inspection allows comprehensive cathodic protection evaluation through direct anode and hull surface access, while underwater inspection relies on visual and sensor-based assessments limiting detailed anode condition analysis.

Anode integrity check

Dry docking inspection provides comprehensive anode integrity checks through direct visual and physical examination, while underwater inspection relies on remote techniques that may limit detailed assessment of anode condition.

Docking blocks alignment

Docking blocks alignment in dry docking inspections ensures precise hull support and structural integrity, whereas underwater inspections rely on visual and sonar assessments that cannot verify physical block positioning.

ROV (Remotely Operated Vehicle) survey

ROV surveys for underwater inspection provide continuous real-time data on hull condition without vessel downtime, whereas dry docking inspection offers comprehensive inspection opportunities but requires vessel out of service and higher costs.

Shaft seal inspection

Shaft seal inspection during dry docking allows for comprehensive visual and physical evaluation of seals and associated components, while underwater inspection relies on remote or diver assessments that may limit detailed inspection and detection of early seal wear or damage.

Biofouling removal

Dry docking inspection enables thorough biofouling removal by allowing complete hull access, while underwater inspection provides limited biofouling assessment and partial cleaning without vessel removal.

Dry docking inspection vs Underwater inspection Infographic

njnir.com

njnir.com