LNG fuel offers higher energy density and lower greenhouse gas emissions compared to traditional marine fuels, making it a preferred choice for reducing vessel carbon footprints. Methanol fuel provides advantages such as ease of storage and compatibility with existing engine technology, enabling smoother integration into current fleets. Both fuels contribute to cleaner maritime operations, but LNG's established infrastructure often leads to cost efficiencies, whereas methanol excels in renewable production potential.

Table of Comparison

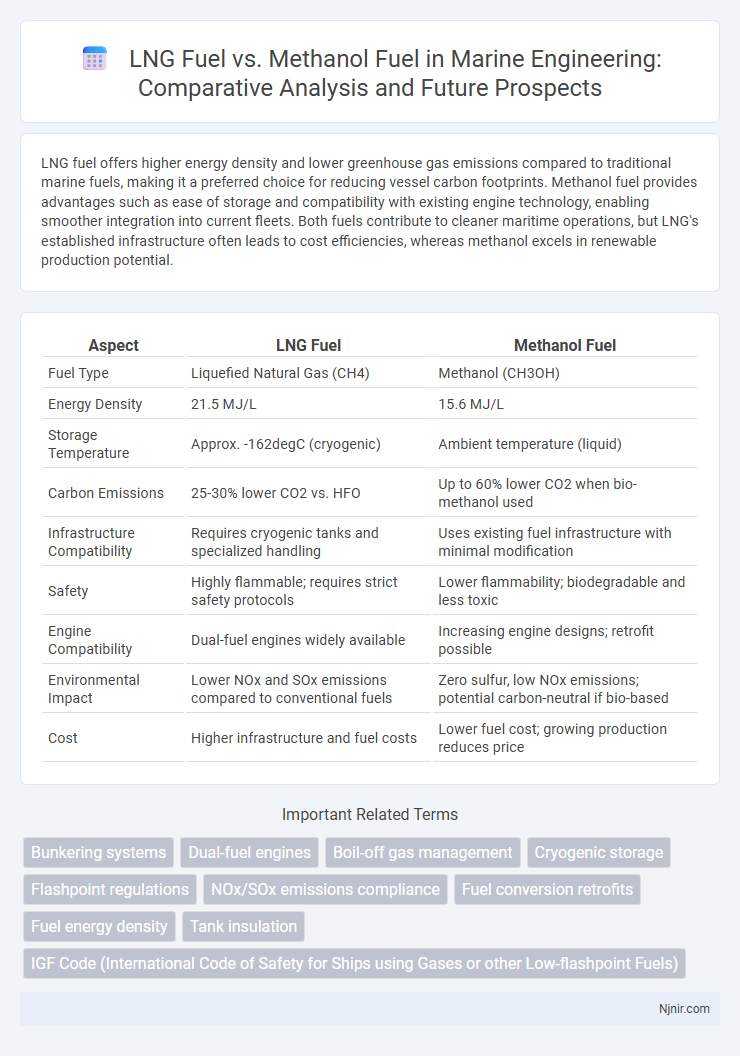

| Aspect | LNG Fuel | Methanol Fuel |

|---|---|---|

| Fuel Type | Liquefied Natural Gas (CH4) | Methanol (CH3OH) |

| Energy Density | 21.5 MJ/L | 15.6 MJ/L |

| Storage Temperature | Approx. -162degC (cryogenic) | Ambient temperature (liquid) |

| Carbon Emissions | 25-30% lower CO2 vs. HFO | Up to 60% lower CO2 when bio-methanol used |

| Infrastructure Compatibility | Requires cryogenic tanks and specialized handling | Uses existing fuel infrastructure with minimal modification |

| Safety | Highly flammable; requires strict safety protocols | Lower flammability; biodegradable and less toxic |

| Engine Compatibility | Dual-fuel engines widely available | Increasing engine designs; retrofit possible |

| Environmental Impact | Lower NOx and SOx emissions compared to conventional fuels | Zero sulfur, low NOx emissions; potential carbon-neutral if bio-based |

| Cost | Higher infrastructure and fuel costs | Lower fuel cost; growing production reduces price |

Overview of LNG and Methanol as Marine Fuels

LNG (liquefied natural gas) as a marine fuel offers lower emissions of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter compared to traditional marine fuels, supporting compliance with IMO 2020 sulfur regulations. Methanol, a liquid alcohol fuel, provides versatility with easier storage and handling and emits fewer greenhouse gases and pollutants, making it a promising alternative for clean shipping. Both fuels contribute to reducing the carbon footprint of maritime operations while addressing regulatory pressures for sustainable marine transport.

Energy Density and Storage Considerations

LNG fuel offers a higher energy density of approximately 55 MJ/kg compared to methanol's 20 MJ/kg, allowing vessels to travel longer distances without refueling. LNG requires cryogenic storage at around -162degC, necessitating specialized insulated tanks that increase initial investment and spatial requirements. Methanol stores at ambient temperature in conventional tanks, simplifying storage infrastructure but requiring more frequent refueling due to its lower energy density.

Emission Profiles and Environmental Impact

LNG fuel emits significantly lower levels of sulfur oxides (SOx) and particulate matter compared to methanol fuel, contributing to reduced air pollution in maritime and industrial applications. Methanol fuel, while producing higher carbon dioxide (CO2) emissions than LNG, offers advantages with lower nitrogen oxides (NOx) and almost negligible sulfur emissions, benefiting local air quality. Both fuels present environmental trade-offs where LNG's lower greenhouse gas footprint contrasts with methanol's potential for renewable production and biodegradability.

Fuel Availability and Global Infrastructure

LNG fuel benefits from well-established global infrastructure with extensive bunkering facilities concentrated in key maritime hubs such as Singapore, Rotterdam, and the U.S. Gulf Coast, enabling broad fuel availability for international shipping. Methanol fuel infrastructure is rapidly expanding, supported by growing production capacity from natural gas and biomass, particularly in Asia and Europe, though overall bunkering networks remain limited compared to LNG. The ongoing investments in methanol bunkering stations and distribution logistics indicate a strong potential for enhanced availability, but LNG currently holds an advantage in global refueling accessibility.

Engine Technology and Adaptation Requirements

LNG fuel engines require cryogenic storage and specialized fuel injection systems to handle the low-temperature, high-density properties of liquefied natural gas, demanding modifications in fuel supply and combustion control for optimal efficiency. Methanol fuel engines utilize flexible fuel systems compatible with existing diesel engines, often requiring only minor adaptations such as corrosion-resistant materials and optimized ignition timing due to methanol's lower energy density and higher octane rating. Both fuel types necessitate advancements in engine calibration and emission control technologies to meet stringent environmental regulations while maintaining performance and fuel economy.

Safety and Handling Procedures

LNG fuel requires cryogenic storage at extremely low temperatures, necessitating specialized insulated tanks and strict handling protocols to prevent boil-off and potential leaks, which pose fire and explosion risks. Methanol fuel, being liquid at ambient conditions, offers easier storage and transport with lower flammability hazards but demands careful handling due to its toxicity and corrosiveness. Both fuels mandate rigorous safety measures, with LNG emphasizing thermal insulation and leak detection systems, while methanol requires corrosion-resistant materials and spill containment procedures.

Regulatory Compliance and Future Mandates

LNG fuel demonstrates strong regulatory compliance with the International Maritime Organization's (IMO) sulfur oxide (SOx) and nitrogen oxide (NOx) emissions limits, aligning with the IMO 2020 sulfur cap and upcoming Tier III standards. Methanol fuel offers advantages in meeting future mandates due to its carbon-neutral potential and compatibility with existing marine engines, supporting the transition to low-carbon shipping under the IMO's 2050 greenhouse gas reduction strategy. Both fuels are subject to evolving regulations, but methanol's ability to be produced from renewable sources positions it favorably for stricter carbon intensity and decarbonization requirements.

Lifecycle Costs and Economic Viability

LNG fuel offers lower lifecycle costs due to its higher energy density and established supply infrastructure, resulting in reduced operational expenses and longer engine lifespan. Methanol fuel, while potentially cheaper upfront and easier to store, incurs higher lifecycle costs because of lower energy content and increased fuel consumption rates. Economic viability favors LNG in large-scale, long-duration maritime applications, whereas methanol may provide cost benefits in short routes and smaller vessels due to flexibility and lower initial investment.

Operational Performance and Vessel Compatibility

LNG fuel offers superior energy density and lower emissions, enhancing vessel operational efficiency and compliance with stringent environmental regulations. Methanol fuel provides easier storage and handling due to its liquid state at ambient temperature, allowing for greater vessel compatibility without extensive modification. Both fuels support reduced greenhouse gas emissions, but LNG's cryogenic requirements may limit retrofitting options compared to methanol's adaptability for various ship types.

Future Trends and Industry Outlook

LNG fuel is projected to dominate the marine energy sector due to its lower emissions and widespread infrastructure development, driven by stringent IMO regulations targeting sulfur and greenhouse gas reductions. Methanol fuel is gaining momentum as a versatile alternative with carbon-neutral potential, supported by increasing investments in renewable methanol production and pilot projects in shipping and heavy transport. Future trends indicate a hybrid approach where LNG and methanol coexist, leveraging LNG's mature supply chain and methanol's sustainability benefits to meet evolving environmental standards.

Bunkering systems

LNG bunkering systems require cryogenic infrastructure for fuel storage and transfer, while methanol bunkering systems utilize ambient temperature tanks and simpler handling equipment, making methanol bunkering more flexible and faster to deploy in port facilities.

Dual-fuel engines

Dual-fuel engines using LNG fuel offer higher energy density and lower carbon emissions compared to methanol fuel, enhancing efficiency and environmental performance in marine propulsion.

Boil-off gas management

Efficient boil-off gas management in LNG fuel systems minimizes methane slip and energy loss, whereas methanol fuel systems inherently avoid boil-off gas issues due to methanol's liquid stability at ambient temperature.

Cryogenic storage

LNG fuel requires storage at approximately -162degC in highly insulated cryogenic tanks to maintain its liquid state, whereas methanol fuel is stored at ambient temperature, eliminating the need for cryogenic storage systems.

Flashpoint regulations

LNG fuel typically has a flashpoint below -188degC classifying it as a cryogenic liquid with stringent handling regulations, whereas methanol fuel has a flashpoint of approximately 11degC, requiring less restrictive safety measures under most maritime fuel regulations.

NOx/SOx emissions compliance

LNG fuel significantly reduces NOx and SOx emissions compared to methanol fuel, making it more compliant with stringent maritime environmental regulations.

Fuel conversion retrofits

LNG fuel retrofits typically require complex cryogenic handling systems and high-pressure storage modifications, whereas methanol fuel conversions demand less extensive changes due to its liquid state at ambient temperature and compatibility with existing fuel injection systems.

Fuel energy density

LNG fuel has a higher energy density of approximately 55 MJ/kg compared to methanol's lower energy density of around 20 MJ/kg, making LNG more efficient for long-duration marine and heavy-duty applications.

Tank insulation

LNG fuel tanks require advanced vacuum-insulated cryogenic systems to maintain temperatures around -162degC, while methanol fuel tanks use simpler thermal insulation due to methanol's ambient storage temperature, making LNG tank insulation more complex and costly.

IGF Code (International Code of Safety for Ships using Gases or other Low-flashpoint Fuels)

The IGF Code provides specific safety guidelines and regulations for ships using LNG fuel and methanol fuel, emphasizing hazard prevention, tank design, ventilation, and fire safety tailored to the distinct properties of these low-flashpoint fuels.

LNG fuel vs Methanol fuel Infographic

njnir.com

njnir.com