Closed-loop scrubbers recycle wash water through a treatment system before discharge, minimizing environmental impact and complying with stricter regulations in sensitive waters. Open-loop scrubbers use seawater directly to cleanse exhaust gases and discharge the wash water back to the sea without treatment, making them effective in open ocean but restricted in areas with tight environmental controls. Choosing between closed-loop and open-loop scrubbers depends on operational areas, regulatory compliance, and environmental sustainability goals in marine engineering.

Table of Comparison

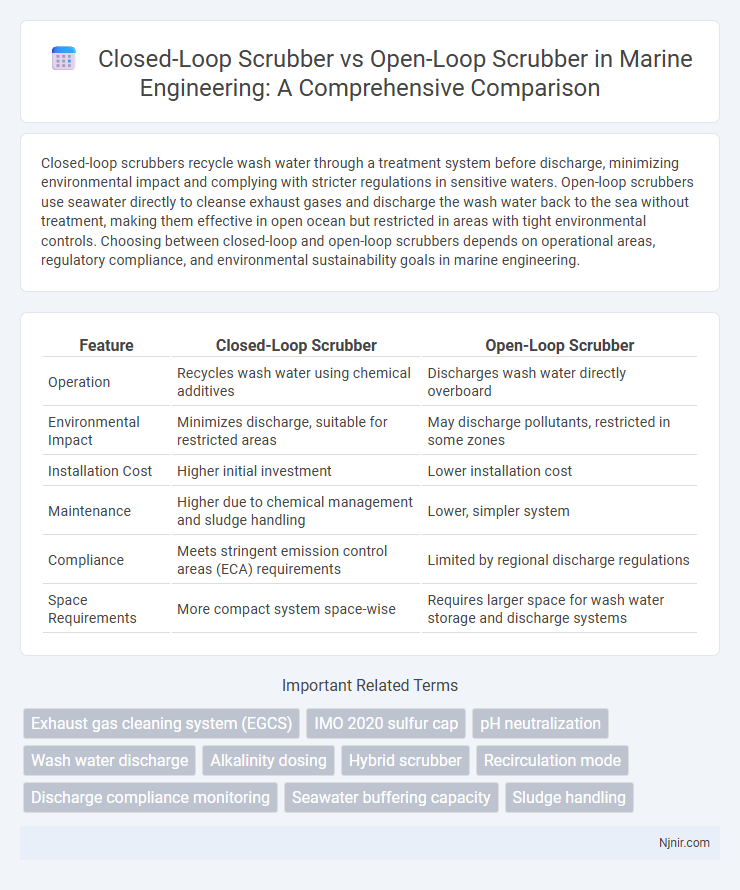

| Feature | Closed-Loop Scrubber | Open-Loop Scrubber |

|---|---|---|

| Operation | Recycles wash water using chemical additives | Discharges wash water directly overboard |

| Environmental Impact | Minimizes discharge, suitable for restricted areas | May discharge pollutants, restricted in some zones |

| Installation Cost | Higher initial investment | Lower installation cost |

| Maintenance | Higher due to chemical management and sludge handling | Lower, simpler system |

| Compliance | Meets stringent emission control areas (ECA) requirements | Limited by regional discharge regulations |

| Space Requirements | More compact system space-wise | Requires larger space for wash water storage and discharge systems |

Introduction to Marine Scrubber Systems

Marine scrubber systems reduce sulfur oxide emissions from ship exhaust, complying with IMO 2020 fuel sulfur limits. Closed-loop scrubbers recycle wash water internally, minimizing discharge by treating and recirculating it, making them suitable for sensitive or restricted waters. Open-loop scrubbers discharge treated wash water directly into the sea, relying on natural dilution, and are often preferred for unrestricted open ocean operations due to lower operational complexity.

Overview of Closed-Loop Scrubber Technology

Closed-loop scrubber technology recirculates wash water within the system, minimizing discharge into the sea and effectively reducing harmful emissions such as sulfur oxides (SOx) from ships. This system uses a combination of seawater filtration and chemical additives to neutralize pollutants, allowing it to operate in ecologically sensitive or emission-controlled areas without compromising environmental standards. Closed-loop scrubbers are preferred in regions with strict discharge regulations due to their ability to treat and reuse wash water, contrasting with open-loop scrubbers that directly discharge treated water back into the marine environment.

Overview of Open-Loop Scrubber Technology

Open-loop scrubbers operate by drawing in seawater to neutralize and remove sulfur oxides (SOx) from ship exhaust gases, then discharging the treated water back into the sea. This technology relies on naturally alkaline seawater to absorb and neutralize emissions without the need for additional chemicals. Open-loop systems are favored for their lower operational complexity and reduced maintenance compared to closed-loop scrubbers, but their use is regulated in certain environmentally sensitive areas due to potential water discharge impacts.

Emission Reduction Efficiency Comparison

Closed-loop scrubbers achieve higher emission reduction efficiency by recycling wash water and removing nearly 99% of sulfur oxides (SOx) from ship exhaust gases, making them ideal for sensitive areas with strict environmental regulations. Open-loop scrubbers discharge wash water directly into the sea after neutralizing acidic compounds, which can reduce installation costs but may have variable emission control based on water alkalinity and local discharge regulations. Studies show closed-loop systems consistently outperform open-loop scrubbers in removing particulate matter and nitrogen oxides (NOx), providing more comprehensive pollution mitigation for maritime vessels.

Environmental Impact Assessment

Closed-loop scrubbers recycle wash water through treatment systems, significantly reducing the discharge of harmful pollutants like sulfur oxides and heavy metals into marine environments. Open-loop scrubbers discharge untreated wash water directly into the sea, posing higher risks of water contamination and negative effects on marine ecosystems. Environmental Impact Assessments highlight closed-loop scrubbers as a more sustainable option for minimizing acid rain and protecting biodiversity in sensitive waters.

Installation and Operational Costs

Closed-loop scrubbers typically require higher initial installation costs due to complex equipment and additional tanks for chemical storage, but their operational costs are lower because they recycle wash water and produce less discharge. Open-loop scrubbers have lower installation expenses since they rely on ambient seawater for scrubbing, requiring fewer components, but their operational costs can increase with fuel consumption and water treatment demands in areas with strict discharge regulations. Shipowners must weigh higher upfront investments in closed-loop systems against ongoing operational savings and regulatory compliance benefits.

Maintenance and Reliability Factors

Closed-loop scrubbers require regular maintenance of water treatment systems and chemical dosing equipment to prevent scaling and corrosion, ensuring consistent reliability in varied water conditions. Open-loop scrubbers rely on seawater for exhaust gas cleaning, demanding less intensive onboard water treatment but facing potential operational limitations in low-salinity or protected waters. Maintenance challenges differ with closed-loop systems focusing on complex filtration and disposal of waste sludge, whereas open-loop systems prioritize seawater intake integrity and anti-fouling measures to maintain optimal performance.

Regulatory Compliance and Restrictions

Closed-loop scrubbers operate by recycling wash water through treatment systems, ensuring minimal discharge and compliance with strict environmental regulations in Emission Control Areas (ECAs) and countries with stringent sulfur oxide (SOx) emission limits. Open-loop scrubbers discharge wash water directly into the sea, subject to restrictions or bans in many coastal and protected waters due to concerns about water pollution and marine ecosystem impact. Regulatory compliance increasingly favors closed-loop systems in regions enforcing zero-discharge policies, driving shipping companies to adopt closed-loop scrubbers to meet international Maritime Organization (IMO) sulfur cap regulations and local environmental laws.

Suitability for Different Vessel Types

Closed-loop scrubbers are highly suitable for vessels operating in Emission Control Areas (ECAs) and areas with strict sulfur oxide (SOx) regulations, such as passenger ships and cruise liners, due to their minimal discharge of wash water. Open-loop scrubbers are ideal for larger bulk carriers and tankers operating primarily in open sea areas where wash water discharge regulations are less stringent. Hybrid scrubbers offer flexibility, making them well-suited for vessels requiring compliance across diverse regions with varying environmental regulations.

Future Trends in Marine Scrubber Systems

Future trends in marine scrubber systems emphasize the integration of hybrid scrubbers that combine closed-loop and open-loop functionalities to optimize sulfur oxide (SOx) emissions reduction and environmental compliance. Advances in sensor technology and real-time monitoring enable more efficient water treatment and reduced discharge impacts, aligning with stricter International Maritime Organization (IMO) regulations. Emerging developments also focus on eco-friendly scrubber water treatment chemicals and increased automation for minimizing operational costs and enhancing system reliability.

Exhaust gas cleaning system (EGCS)

Closed-loop scrubbers recycle and treat exhaust gas cleaning system (EGCS) wash water internally, minimizing environmental discharge, while open-loop scrubbers discharge untreated wash water directly into the sea, relying on natural dilution.

IMO 2020 sulfur cap

Closed-loop scrubbers recycle wash water internally to meet IMO 2020 sulfur cap regulations by minimizing discharge, while open-loop scrubbers use seawater to absorb sulfur oxides and discharge treated water directly.

pH neutralization

Closed-loop scrubbers maintain pH neutralization by recycling and treating wash water, preventing acid discharge, whereas open-loop scrubbers discharge untreated wash water directly into the sea, resulting in variable and often lower pH levels.

Wash water discharge

Closed-loop scrubbers minimize wash water discharge by recycling treated water within the system, whereas open-loop scrubbers discharge untreated wash water directly into the sea, impacting marine environments.

Alkalinity dosing

Closed-loop scrubbers require precise alkalinity dosing to neutralize acidic byproducts internally, while open-loop scrubbers rely on seawater's natural alkalinity, minimizing the need for external dosing.

Hybrid scrubber

Hybrid scrubbers combine the advantages of closed-loop and open-loop systems by enabling flexible use of seawater or freshwater with chemical additives to optimize emissions control and minimize environmental impact in marine exhaust gas cleaning.

Recirculation mode

Closed-loop scrubbers utilize recirculation mode to continuously clean and reuse wash water, reducing discharge and environmental impact compared to open-loop scrubbers that discharge untreated water directly into the sea.

Discharge compliance monitoring

Closed-loop scrubbers continuously monitor and treat discharge water onsite to ensure compliance with stringent environmental regulations, while open-loop scrubbers rely on real-time seawater quality parameters but face challenges in maintaining consistent discharge compliance monitoring.

Seawater buffering capacity

Closed-loop scrubbers rely on seawater buffering capacity to neutralize acidic emissions internally, whereas open-loop scrubbers continuously discharge treated wash water back into the sea, depending heavily on the local seawater's high buffering capacity to dilute and neutralize pollutants.

Sludge handling

Closed-loop scrubbers produce concentrated sludge requiring onshore disposal, while open-loop scrubbers generate dilute sludge discharged into the sea, minimizing onboard handling.

Closed-loop scrubber vs Open-loop scrubber Infographic

njnir.com

njnir.com