Acoustic emission testing detects transient elastic waves generated by the rapid release of energy from localized sources within marine structures, enabling real-time monitoring of crack growth and corrosion. Ultrasonic testing uses high-frequency sound waves transmitted into materials to identify internal flaws, measure thickness, and assess weld integrity with precise depth information. Both methods are integral in marine engineering for ensuring structural integrity, but acoustic emission is more suited for continuous monitoring while ultrasonic testing offers detailed localized inspections.

Table of Comparison

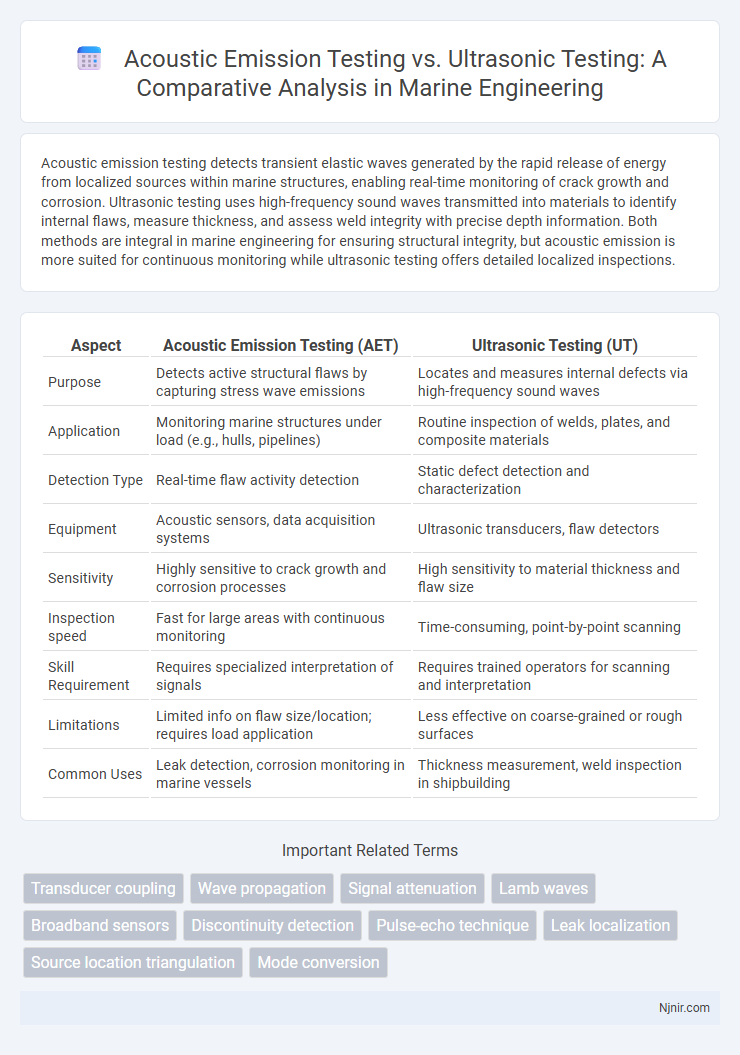

| Aspect | Acoustic Emission Testing (AET) | Ultrasonic Testing (UT) |

|---|---|---|

| Purpose | Detects active structural flaws by capturing stress wave emissions | Locates and measures internal defects via high-frequency sound waves |

| Application | Monitoring marine structures under load (e.g., hulls, pipelines) | Routine inspection of welds, plates, and composite materials |

| Detection Type | Real-time flaw activity detection | Static defect detection and characterization |

| Equipment | Acoustic sensors, data acquisition systems | Ultrasonic transducers, flaw detectors |

| Sensitivity | Highly sensitive to crack growth and corrosion processes | High sensitivity to material thickness and flaw size |

| Inspection speed | Fast for large areas with continuous monitoring | Time-consuming, point-by-point scanning |

| Skill Requirement | Requires specialized interpretation of signals | Requires trained operators for scanning and interpretation |

| Limitations | Limited info on flaw size/location; requires load application | Less effective on coarse-grained or rough surfaces |

| Common Uses | Leak detection, corrosion monitoring in marine vessels | Thickness measurement, weld inspection in shipbuilding |

Overview of Acoustic Emission Testing in Marine Engineering

Acoustic emission testing (AET) in marine engineering monitors structural integrity by detecting transient elastic waves generated by crack formation and material deformation. This non-destructive technique provides real-time damage assessment, enabling early identification of corrosion, fatigue, and welding defects in ship hulls and offshore structures. By contrast, ultrasonic testing (UT) relies on high-frequency sound waves to detect internal flaws, offering precise thickness measurements but typically requires more detailed surface preparation and access.

Fundamentals of Ultrasonic Testing for Ship Structures

Ultrasonic testing for ship structures relies on high-frequency sound waves to detect internal flaws and measure material thickness, ensuring structural integrity and safety. This nondestructive testing method transmits ultrasonic pulses into the ship's metal, analyzing the reflected signals from defects like cracks, corrosion, or weld discontinuities. The precision and depth penetration of ultrasonic testing make it highly effective for inspecting large ship hulls and critical components compared to acoustic emission testing, which monitors sound emissions from active crack growth or material deformation.

Comparative Principles: Acoustic Emission vs Ultrasonic Testing

Acoustic emission testing detects transient stress waves emitted from the rapid release of energy within materials, making it ideal for monitoring active damage such as crack growth in real-time. Ultrasonic testing uses high-frequency sound waves transmitted into the material to identify internal flaws by analyzing wave reflections, providing detailed information about defect size and location. While acoustic emission captures dynamic fracture events and structural changes, ultrasonic testing offers precise imaging for static flaw detection, each leveraging distinct wave propagation principles for nondestructive evaluation.

Detection Capabilities for Corrosion and Cracks

Acoustic emission testing excels in detecting active corrosion and crack propagation by capturing transient elastic waves generated from structural defects, offering real-time monitoring of material degradation. Ultrasonic testing provides high-resolution imaging capable of identifying both surface and subsurface corrosion and cracks, enabling precise sizing and location of defects through pulse-echo or through-transmission techniques. While acoustic emission is suited for early detection during service, ultrasonic testing delivers detailed characterization for maintenance planning and defect evaluation.

Sensitivity and Accuracy in Marine Applications

Acoustic emission testing (AET) is highly sensitive to active crack growth and flaw development in marine structures, capturing transient elastic waves emitted during material deformation, making it ideal for real-time monitoring of hull integrity and corrosion under insulation. Ultrasonic testing (UT) offers greater accuracy in sizing and locating existing defects, utilizing high-frequency sound waves for precise thickness measurements and flaw detection in ship hulls and offshore components, essential for routine inspections and maintenance. Sensitivity of AET enables early detection of dynamic damage processes, while UT provides detailed characterization of defect dimensions, making their combined application critical for comprehensive marine asset integrity management.

Suitability for In-Service Monitoring

Acoustic emission testing excels in in-service monitoring by detecting real-time crack growth, corrosion, and structural changes through stress-induced wave emissions, making it highly effective for continuous surveillance of critical components. Ultrasonic testing, while providing detailed internal flaw characterization, often requires component shutdowns and coupling media, limiting its practicality for continuous, in-service monitoring. The non-intrusive nature of acoustic emission combined with its sensitivity to active defect generation offers superior suitability for ongoing condition assessment in operational environments.

Equipment and Operational Requirements

Acoustic emission testing requires sensitive piezoelectric sensors capable of detecting transient elastic waves emitted from crack formation or material deformation, often necessitating continuous monitoring equipment and advanced signal processing units. Ultrasonic testing relies on high-frequency transducers that generate and receive sound waves, demanding precise pulse-echo or through-transmission devices along with couplants to facilitate efficient wave transmission. Both methods require calibrated instrumentation and skilled operators, but ultrasonic testing equipment typically involves more portable, hand-held devices, whereas acoustic emission setups often include stationary sensor arrays for real-time structural health monitoring.

Data Interpretation and Analysis Methods

Acoustic emission testing relies on real-time monitoring of transient elastic waves generated by crack formation or material deformation, with data interpretation focused on signal amplitude, energy, and source location using waveform analysis and pattern recognition algorithms. Ultrasonic testing employs high-frequency sound waves transmitted through materials, where data analysis involves measuring signal time-of-flight, amplitude, and frequency shifts to detect flaws and characterize defects via A-scan, B-scan, or C-scan imaging techniques. Advanced signal processing methods such as Fast Fourier Transform (FFT) and machine learning enhance the accuracy and reliability of defect identification in both testing modalities.

Cost and Efficiency in Ship Maintenance

Acoustic emission testing (AET) offers cost-effective continuous monitoring for early detection of structural flaws in ships, reducing downtime and maintenance costs. Ultrasonic testing (UT) provides high efficiency in detecting precise internal defects with rapid results but often requires skilled operators and higher equipment investment. In ship maintenance, combining AET for ongoing surveillance with periodic UT inspections optimizes cost efficiency and enhances overall structural integrity assessment.

Future Trends in Non-Destructive Testing for Marine Engineering

Future trends in non-destructive testing (NDT) for marine engineering highlight increased integration of acoustic emission testing (AET) and ultrasonic testing (UT) with advanced digital technologies such as artificial intelligence, machine learning, and real-time data analytics. Innovations in sensor miniaturization and improved signal processing are enhancing the sensitivity and accuracy of AET for detecting micro-cracks and corrosion, while next-generation UT systems offer higher resolution imaging and automated flaw characterization. These advancements are driving more efficient, predictive maintenance, reducing downtime and extending the service life of critical marine structures and vessels.

Transducer coupling

Acoustic emission testing relies on passive transducer coupling to detect stress waves from material defects, whereas ultrasonic testing requires active transducer coupling with a coupling medium to transmit and receive high-frequency sound waves through the test material.

Wave propagation

Acoustic emission testing detects transient elastic waves generated by crack growth, while ultrasonic testing emits controlled high-frequency sound waves to measure material thickness and identify internal flaws through wave propagation characteristics.

Signal attenuation

Acoustic emission testing experiences greater signal attenuation over long distances compared to ultrasonic testing, making ultrasonic methods more effective for detecting internal flaws in thick or dense materials.

Lamb waves

Lamb waves in ultrasonic testing enable sensitive detection of surface and subsurface defects, while acoustic emission testing monitors real-time structural integrity by capturing transient elastic waves generated from active damage processes.

Broadband sensors

Broadband sensors in acoustic emission testing detect a wide range of frequencies for real-time crack monitoring, whereas ultrasonic testing uses narrowband pulses for precise flaw detection and material characterization.

Discontinuity detection

Acoustic emission testing excels in real-time monitoring of active discontinuities by detecting transient elastic waves, while ultrasonic testing provides precise localization and sizing of both active and dormant discontinuities through controlled high-frequency wave propagation.

Pulse-echo technique

Ultrasonic testing using the pulse-echo technique employs high-frequency sound waves to detect internal flaws by measuring echo times, while acoustic emission testing monitors real-time stress-induced sound waves emitted by materials under load for early damage detection.

Leak localization

Acoustic emission testing detects and localizes leaks by capturing transient sound waves from active defects, while ultrasonic testing uses high-frequency sound pulses to identify and precisely measure leak locations by reflections within the material.

Source location triangulation

Acoustic emission testing uses real-time source location triangulation by detecting transient elastic waves from active flaws, while ultrasonic testing relies on pulse-echo signals to determine flaw positions but with less dynamic triangulation capability.

Mode conversion

Acoustic emission testing detects real-time stress waves from active defects, while ultrasonic testing relies on mode conversion between longitudinal and shear waves to locate and characterize internal flaws.

Acoustic emission testing vs Ultrasonic testing Infographic

njnir.com

njnir.com