Exhaust scrubbers and selective catalytic reduction (SCR) systems both serve to reduce harmful emissions from marine engines, but they operate differently; scrubbers primarily remove sulfur oxides (SOx) by washing exhaust gases with seawater or chemicals, while SCR systems reduce nitrogen oxides (NOx) by injecting a urea-based solution into the exhaust stream. Scrubbers are effective in meeting sulfur emission regulations under IMO 2020, whereas SCR is critical for compliance with Tier III NOx standards imposed in specific emission control areas. Selecting between these technologies depends on the vessel's operating region, fuel type, and environmental compliance goals, with some ships opting to combine both systems for optimal emission control.

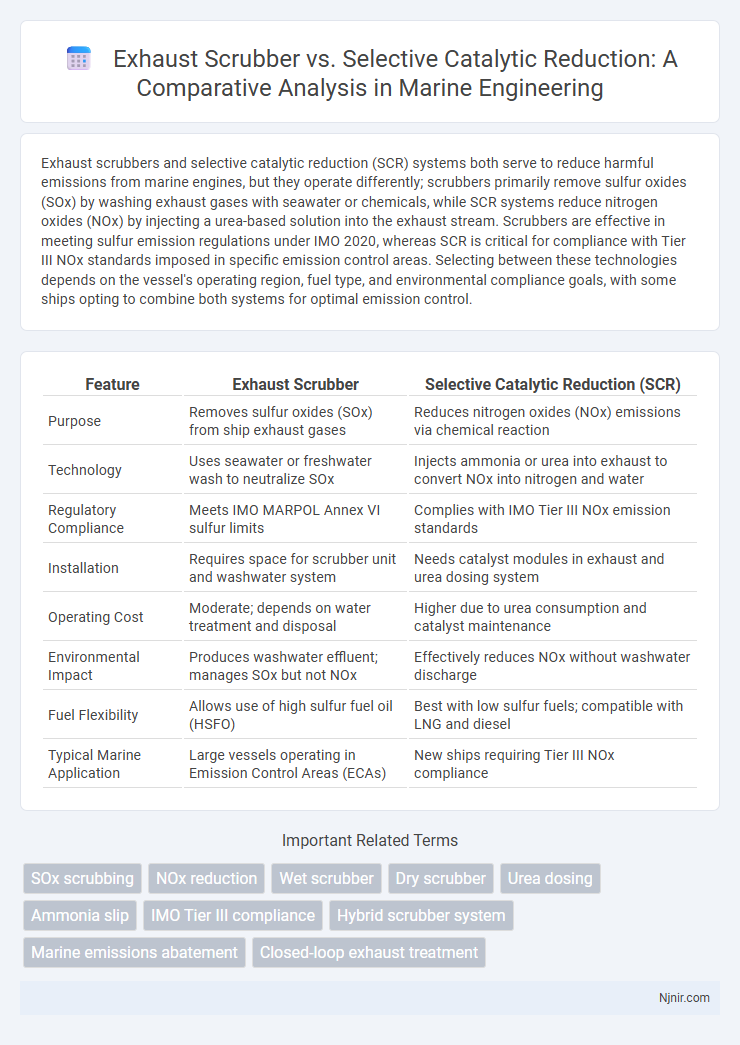

Table of Comparison

| Feature | Exhaust Scrubber | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Removes sulfur oxides (SOx) from ship exhaust gases | Reduces nitrogen oxides (NOx) emissions via chemical reaction |

| Technology | Uses seawater or freshwater wash to neutralize SOx | Injects ammonia or urea into exhaust to convert NOx into nitrogen and water |

| Regulatory Compliance | Meets IMO MARPOL Annex VI sulfur limits | Complies with IMO Tier III NOx emission standards |

| Installation | Requires space for scrubber unit and washwater system | Needs catalyst modules in exhaust and urea dosing system |

| Operating Cost | Moderate; depends on water treatment and disposal | Higher due to urea consumption and catalyst maintenance |

| Environmental Impact | Produces washwater effluent; manages SOx but not NOx | Effectively reduces NOx without washwater discharge |

| Fuel Flexibility | Allows use of high sulfur fuel oil (HSFO) | Best with low sulfur fuels; compatible with LNG and diesel |

| Typical Marine Application | Large vessels operating in Emission Control Areas (ECAs) | New ships requiring Tier III NOx compliance |

Introduction to Marine Emission Control Technologies

Exhaust scrubbers and selective catalytic reduction (SCR) systems are key marine emission control technologies designed to reduce sulfur oxides (SOx) and nitrogen oxides (NOx) emissions, respectively, from ship engines. Exhaust scrubbers use seawater or freshwater to wash out SOx from flue gases, enabling compliance with IMO 2020 sulfur content limits, while SCR systems inject urea-based reductants into the exhaust stream to convert NOx into nitrogen and water, meeting Tier III NOx standards. These technologies play a critical role in minimizing the environmental impact of marine vessels, promoting cleaner air quality and adherence to stringent international maritime regulations.

Overview of Exhaust Gas Scrubbers

Exhaust gas scrubbers use water or chemical solutions to remove sulfur oxides (SOx) and particulate matter from ship emissions, effectively reducing sulfur content to comply with IMO 2020 regulations. These systems capture and neutralize pollutants through wet scrubbers, which can be closed-loop, open-loop, or hybrid, optimizing for environmental impact and operational efficiency. Compared to Selective Catalytic Reduction (SCR), which targets nitrogen oxides (NOx) by converting them into nitrogen and water using ammonia-based reagents, exhaust scrubbers primarily address sulfur emissions, making them essential for sulfur compliance but complementary to NOx reduction technologies.

Understanding Selective Catalytic Reduction (SCR) Systems

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxide (NOx) emissions from diesel engines by injecting a urea-based reductant, such as diesel exhaust fluid (DEF), into the exhaust stream. The reductant reacts with NOx over a catalyst, typically made of materials like titanium dioxide or vanadium pentoxide, converting harmful gases into nitrogen and water vapor, making SCR highly effective for meeting stringent emissions standards. Compared to exhaust scrubbers, which primarily remove particulate matter and sulfur oxides, SCR specifically targets NOx reduction and is widely used in heavy-duty vehicles and industrial applications for efficient exhaust gas cleanup.

Emission Reduction Capabilities: Scrubber vs SCR

Exhaust scrubbers reduce sulfur oxides (SOx) emissions by using seawater or chemical absorbents, achieving up to 98% SOx removal, which is crucial for compliance with IMO sulfur limits. Selective Catalytic Reduction (SCR) targets nitrogen oxides (NOx), converting them into nitrogen and water vapor with reduction efficiencies often exceeding 90%, meeting stringent Tier III marine engine standards. While scrubbers excel in SOx emission control, SCR systems provide superior NOx reduction, making both technologies essential for comprehensive marine emission compliance.

Installation and Integration Considerations

Exhaust scrubbers require significant space and seawater access for installation, making them more suitable for vessels with available deck area and compatible cooling systems. Selective Catalytic Reduction (SCR) systems demand precise integration with the engine's exhaust flow and require continuous dosing of urea solution, necessitating specialized storage and supply systems on board. Both technologies involve modifications to the vessel's existing infrastructure, but SCR typically offers a more compact footprint with potentially lower installation complexity in retrofit scenarios.

Operational Costs and Maintenance Requirements

Exhaust scrubbers typically incur higher operational costs due to substantial water consumption and chemical usage required for pollutant removal, along with complex disposal processes for wastewater. Selective catalytic reduction (SCR) systems generally have lower fuel penalties and consume less consumables, but maintenance involves periodic catalyst replacement and ammonia or urea handling infrastructure upkeep. Both technologies demand regular inspections, yet SCR maintenance tends to be less labor-intensive, offering cost benefits over the scrubber's continuous waste management and water treatment expenses.

Compliance with IMO and Regional Regulations

Exhaust scrubbers effectively reduce sulfur oxide (SOx) emissions, ensuring compliance with MARPOL Annex VI global sulfur caps and specific regional sulfur emission control areas (SECAs). Selective Catalytic Reduction (SCR) systems target nitrogen oxides (NOx), meeting IMO Tier III standards and stringent regional NOx emission limits in Emission Control Areas (ECAs). Both technologies play complementary roles in achieving adherence to international maritime organization regulations and localized environmental mandates.

Impact on Vessel Performance and Efficiency

Exhaust scrubbers reduce sulfur oxide emissions by removing sulfur from engine exhaust gases, often increasing fuel consumption and potentially impacting engine performance due to added backpressure. Selective Catalytic Reduction (SCR) systems target nitrogen oxides emissions by injecting urea into the exhaust stream, generally enhancing combustion efficiency and causing minimal fuel penalty. SCR technology improves vessel efficiency by enabling cleaner combustion processes, whereas scrubbers may require more maintenance and fuel adjustment, affecting overall operational performance.

Environmental and Health Implications

Exhaust scrubbers significantly reduce sulfur oxide (SOx) emissions by removing sulfur compounds from ship exhaust gases, decreasing acid rain and respiratory illnesses linked to air pollution. Selective Catalytic Reduction (SCR) systems target nitrogen oxides (NOx), converting them into harmless nitrogen and water vapor, thereby lowering smog formation and reducing risks of cardiovascular and pulmonary diseases. Both technologies contribute to improved air quality but address different pollutants, making them complementary solutions for minimizing environmental and health impacts from engine emissions.

Future Trends in Marine Emission Solutions

Exhaust scrubbers and selective catalytic reduction (SCR) systems both play crucial roles in reducing marine emissions, with scrubbers focusing on removing sulfur oxides (SOx) through seawater or chemical wash, while SCR targets nitrogen oxides (NOx) by converting them into nitrogen and water using urea-based catalysts. Future trends in marine emission solutions indicate a growing integration of hybrid emission control technologies combining scrubbers and SCR systems for comprehensive pollution reduction, meeting stringent International Maritime Organization (IMO) Tier III standards. Advancements in digital monitoring, automated chemical dosing, and low-maintenance catalyst materials are expected to optimize system efficiency, lower operational costs, and enable wider adoption of eco-friendly shipping practices.

SOx scrubbing

Exhaust scrubbers effectively remove up to 95% of SOx emissions by using seawater or chemical absorbents, whereas Selective Catalytic Reduction primarily targets NOx reduction and does not significantly impact SOx levels.

NOx reduction

Selective catalytic reduction reduces NOx emissions by up to 90% through chemical reactions with ammonia, while exhaust scrubbers primarily target particulate matter and sulfur oxides, offering limited NOx reduction capabilities.

Wet scrubber

Wet exhaust scrubbers effectively remove sulfur oxides and particulate matter from ship emissions using a water spray, contrasting with selective catalytic reduction systems that primarily reduce nitrogen oxides through catalytic chemical reactions.

Dry scrubber

Dry exhaust scrubbers use alkaline sorbents to neutralize acidic gases, offering lower operational costs and simpler maintenance compared to Selective Catalytic Reduction systems that rely on ammonia-based catalysts to reduce NOx emissions.

Urea dosing

Exhaust scrubbers reduce SOx and particulate emissions through chemical scrubbing, while selective catalytic reduction (SCR) systems precisely control urea dosing to convert NOx into nitrogen and water, enhancing nitrogen oxide reduction efficiency.

Ammonia slip

Selective Catalytic Reduction (SCR) systems typically reduce nitrogen oxides with minimal ammonia slip, whereas exhaust scrubbers often experience higher ammonia slip due to less precise ammonia dosing control.

IMO Tier III compliance

Selective Catalytic Reduction (SCR) systems achieve IMO Tier III compliance more effectively than exhaust scrubbers by significantly reducing nitrogen oxide (NOx) emissions from marine engines.

Hybrid scrubber system

The hybrid scrubber system combines exhaust scrubber technology and selective catalytic reduction to simultaneously reduce sulfur oxides (SOx) and nitrogen oxides (NOx) emissions, optimizing maritime pollution control and compliance with IMO and EPA regulations.

Marine emissions abatement

Selective Catalytic Reduction (SCR) systems reduce marine nitrogen oxide (NOx) emissions by up to 90%, while exhaust scrubbers primarily remove sulfur oxides (SOx), making SCR more effective for comprehensive marine emissions abatement.

Closed-loop exhaust treatment

Closed-loop exhaust treatment using exhaust scrubbers captures and recycles pollutants to minimize waste, while selective catalytic reduction (SCR) systems convert NOx emissions into nitrogen and water through precise chemical reactions, offering distinct advantages in emission control efficiency.

exhaust scrubber vs selective catalytic reduction Infographic

njnir.com

njnir.com