Enhancing ship energy efficiency directly reduces fuel consumption, thereby lowering greenhouse gas emissions and operational costs. Advanced technologies such as optimized hull design, energy-efficient propulsion systems, and waste heat recovery contribute significantly to minimizing the environmental impact of marine vessels. Implementing these measures aligns with international regulations while promoting sustainable shipping and reducing the carbon footprint of maritime operations.

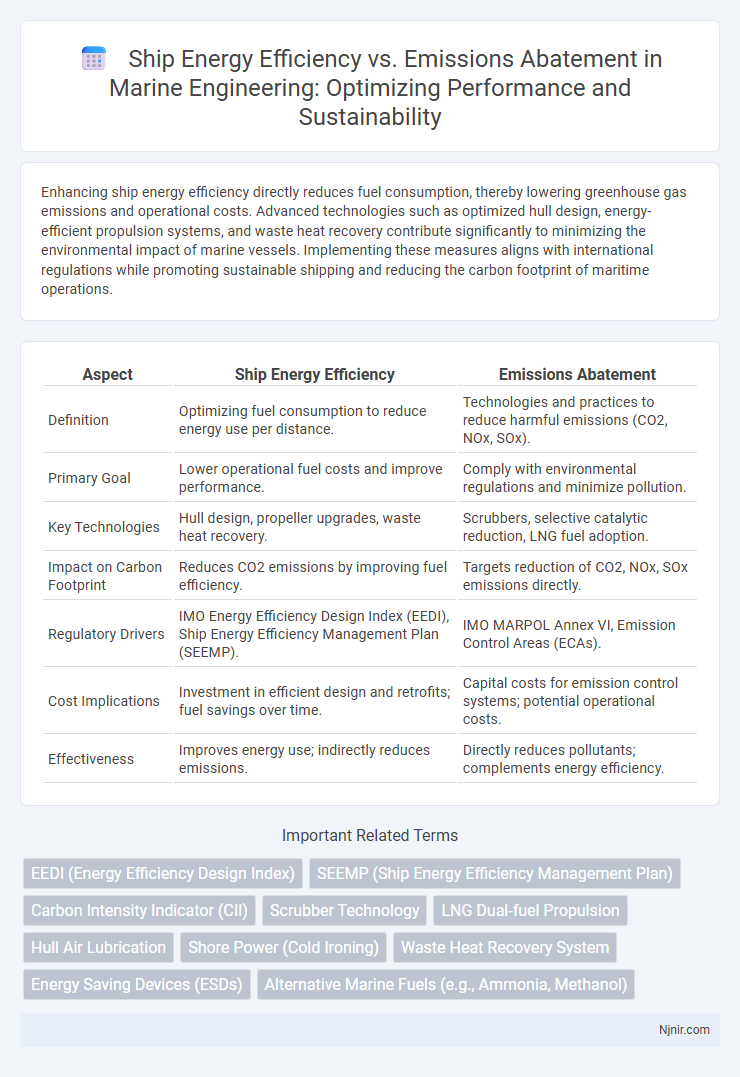

Table of Comparison

| Aspect | Ship Energy Efficiency | Emissions Abatement |

|---|---|---|

| Definition | Optimizing fuel consumption to reduce energy use per distance. | Technologies and practices to reduce harmful emissions (CO2, NOx, SOx). |

| Primary Goal | Lower operational fuel costs and improve performance. | Comply with environmental regulations and minimize pollution. |

| Key Technologies | Hull design, propeller upgrades, waste heat recovery. | Scrubbers, selective catalytic reduction, LNG fuel adoption. |

| Impact on Carbon Footprint | Reduces CO2 emissions by improving fuel efficiency. | Targets reduction of CO2, NOx, SOx emissions directly. |

| Regulatory Drivers | IMO Energy Efficiency Design Index (EEDI), Ship Energy Efficiency Management Plan (SEEMP). | IMO MARPOL Annex VI, Emission Control Areas (ECAs). |

| Cost Implications | Investment in efficient design and retrofits; fuel savings over time. | Capital costs for emission control systems; potential operational costs. |

| Effectiveness | Improves energy use; indirectly reduces emissions. | Directly reduces pollutants; complements energy efficiency. |

Introduction to Ship Energy Efficiency and Emissions Abatement

Ship energy efficiency focuses on reducing fuel consumption through advanced hull designs, optimized propulsion systems, and energy-saving technologies. Emissions abatement targets the reduction of harmful pollutants such as sulfur oxides (SOx), nitrogen oxides (NOx), and carbon dioxide (CO2) via cleaner fuels, exhaust gas cleaning systems, and alternative energy sources like LNG or hydrogen. Balancing energy efficiency with stringent emissions regulations is essential for sustainable maritime operations and compliance with IMO standards.

Regulatory Framework: IMO and MARPOL Guidelines

The International Maritime Organization (IMO) establishes the primary regulatory framework for ship energy efficiency and emissions abatement through mandatory instruments such as MARPOL Annex VI, which sets limits on nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter emissions. The Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) are critical IMO measures aimed at reducing greenhouse gas emissions by improving vessel design and operational performance. Compliance with these regulations is enforced globally, ensuring shipping companies adopt cleaner technologies and optimize fuel consumption to meet increasingly stringent environmental standards.

Key Drivers for Improving Ship Energy Efficiency

Key drivers for improving ship energy efficiency include advancements in hull design, which reduce hydrodynamic resistance and fuel consumption, along with the adoption of energy-saving technologies such as air lubrication systems and waste heat recovery systems. Implementation of slow steaming practices and optimized voyage planning using digital tools also significantly decrease fuel usage and carbon emissions. Increasing regulatory pressure from the International Maritime Organization (IMO) and market-based measures incentivize shipowners to invest in cleaner propulsion methods and alternative fuels like LNG and hydrogen.

Technologies for Onboard Energy Optimization

Technologies for onboard energy optimization significantly enhance ship energy efficiency while reducing emissions abatement costs. Advanced energy management systems integrate real-time data analytics and intelligent automation to optimize fuel consumption and minimize greenhouse gas emissions. Innovations such as waste heat recovery systems, energy-efficient propulsion units, and hybrid power sources further contribute to sustainable maritime operations by lowering carbon footprints and operational expenses.

Alternative Fuels: LNG, Biofuels, and Hydrogen

Alternative fuels such as LNG, biofuels, and hydrogen significantly improve ship energy efficiency and reduce emissions abatement by lowering carbon dioxide, sulfur oxides, and nitrogen oxides output compared to conventional marine fuels. LNG offers a cleaner combustion profile with up to 25% lower CO2 emissions, biofuels provide a renewable carbon cycle contributing to net-zero targets, and hydrogen produces zero emissions at point of use, making it a promising solution for decarbonizing the shipping industry. The integration of these fuels supports compliance with IMO 2030 and 2050 emission reduction targets while enhancing operational energy efficiency through advanced engine technologies and optimized fuel management systems.

Operational Strategies for Emissions Reduction

Operational strategies for ship energy efficiency emphasize optimizing voyage planning, speed reduction, and hull cleaning to minimize fuel consumption and lower greenhouse gas emissions. Implementing real-time monitoring systems and energy management software enables precise adjustments to engine performance and auxiliary systems, enhancing overall vessel efficiency. Integrating slow steaming with route optimization can reduce emissions abatement costs significantly while maintaining shipping schedules and compliance with international maritime regulations.

Energy Efficiency Design Index (EEDI) and Ship Performance

The Energy Efficiency Design Index (EEDI) serves as a critical regulatory framework aimed at reducing greenhouse gas emissions by promoting energy-efficient ship designs. Enhancing ship performance through optimized hull structures, advanced propulsion systems, and energy-saving technologies directly supports compliance with EEDI requirements, leading to significant reductions in fuel consumption and carbon emissions. Continuous monitoring and retrofitting of existing vessels further contribute to emissions abatement by improving operational efficiency and minimizing environmental impact.

Exhaust Gas Cleaning Systems (Scrubbers) and Emissions Control

Exhaust Gas Cleaning Systems (Scrubbers) significantly enhance ship energy efficiency by enabling the use of high-sulfur fuel while reducing sulfur oxide (SOx) emissions to comply with IMO regulations. These scrubbers reduce the need for low-sulfur fuel, resulting in operational cost savings and lower greenhouse gas emissions, contributing to effective emissions abatement. Effective emissions control through scrubber technology supports maritime decarbonization efforts by minimizing air pollutants without compromising vessel performance.

Economic Impacts of Energy Efficiency Measures

Implementing ship energy efficiency measures significantly reduces fuel consumption, leading to substantial cost savings in operational expenses. Enhanced energy efficiency also mitigates emissions, helping vessels comply with increasingly stringent international regulations like IMO 2020 and the Carbon Intensity Indicator (CII) requirements, thus avoiding potential fines and penalties. Investment in energy-efficient technologies can improve asset value and market competitiveness, balancing upfront costs with long-term economic benefits in the shipping industry.

Future Trends in Sustainable Marine Engineering

Future trends in sustainable marine engineering emphasize advanced hull designs and propulsion systems to enhance ship energy efficiency while reducing emissions abatement costs. Integration of alternative fuels such as green hydrogen and ammonia alongside energy recovery technologies supports significant reductions in greenhouse gas emissions. Digital optimization through AI-driven route planning and real-time engine monitoring further boosts fuel efficiency and aligns with international IMO regulations targeting carbon neutrality by 2050.

EEDI (Energy Efficiency Design Index)

The Energy Efficiency Design Index (EEDI) quantifies a ship's CO2 emissions per ton-mile, driving global regulations to enhance vessel energy efficiency and reduce greenhouse gas emissions in maritime transport.

SEEMP (Ship Energy Efficiency Management Plan)

Implementing the SEEMP (Ship Energy Efficiency Management Plan) significantly enhances ship energy efficiency by optimizing fuel consumption and operational practices, thereby reducing emissions and supporting global maritime environmental regulations.

Carbon Intensity Indicator (CII)

The Carbon Intensity Indicator (CII) quantifies a ship's energy efficiency by measuring CO2 emissions per transport work, enabling targeted emissions abatement strategies to reduce maritime carbon footprints.

Scrubber Technology

Scrubber technology significantly enhances ship energy efficiency by enabling the use of high-sulfur fuel oils while drastically reducing sulfur oxide emissions to comply with environmental regulations.

LNG Dual-fuel Propulsion

LNG dual-fuel propulsion significantly enhances ship energy efficiency while reducing emissions by lowering sulfur oxides, nitrogen oxides, and carbon dioxide levels compared to conventional marine fuels.

Hull Air Lubrication

Hull air lubrication technology significantly enhances ship energy efficiency by reducing hull friction, directly lowering fuel consumption and emissions abatement.

Shore Power (Cold Ironing)

Shore power (cold ironing) significantly reduces ship emissions by allowing vessels to shut down onboard engines and connect to onshore electrical grids, enhancing energy efficiency and minimizing environmental impact.

Waste Heat Recovery System

Waste Heat Recovery Systems on ships significantly enhance energy efficiency by capturing exhaust heat to reduce fuel consumption and lower greenhouse gas emissions.

Energy Saving Devices (ESDs)

Energy Saving Devices (ESDs) significantly enhance ship energy efficiency by reducing fuel consumption and lowering greenhouse gas emissions, thereby supporting effective emissions abatement in maritime operations.

Alternative Marine Fuels (e.g., Ammonia, Methanol)

Alternative marine fuels such as ammonia and methanol significantly improve ship energy efficiency and reduce emissions by offering lower carbon footprints and enabling cleaner combustion technologies.

Ship Energy Efficiency vs Emissions Abatement Infographic

njnir.com

njnir.com