Waterjet propulsion offers superior maneuverability and shallow water operation compared to traditional screw propellers, making it ideal for high-speed vessels and rescue boats. It reduces the risk of damage from debris and provides enhanced safety for swimmers and marine life due to the absence of exposed rotating blades. While screw propellers generally offer higher propulsion efficiency at lower speeds, waterjet systems excel in applications requiring rapid acceleration and precise control.

Table of Comparison

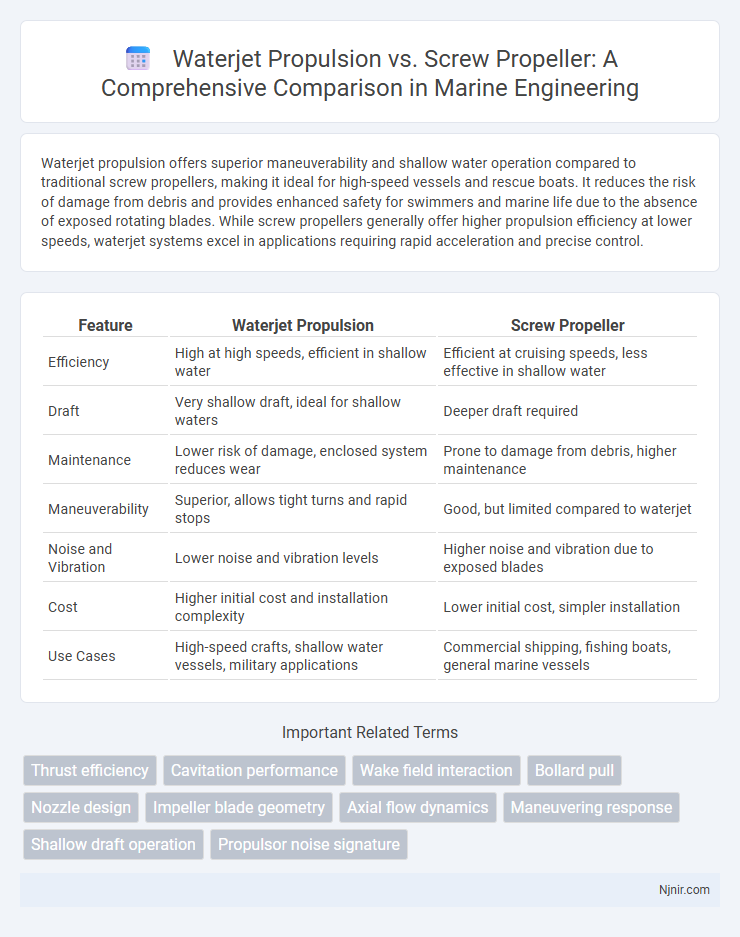

| Feature | Waterjet Propulsion | Screw Propeller |

|---|---|---|

| Efficiency | High at high speeds, efficient in shallow water | Efficient at cruising speeds, less effective in shallow water |

| Draft | Very shallow draft, ideal for shallow waters | Deeper draft required |

| Maintenance | Lower risk of damage, enclosed system reduces wear | Prone to damage from debris, higher maintenance |

| Maneuverability | Superior, allows tight turns and rapid stops | Good, but limited compared to waterjet |

| Noise and Vibration | Lower noise and vibration levels | Higher noise and vibration due to exposed blades |

| Cost | Higher initial cost and installation complexity | Lower initial cost, simpler installation |

| Use Cases | High-speed crafts, shallow water vessels, military applications | Commercial shipping, fishing boats, general marine vessels |

Introduction to Marine Propulsion Systems

Waterjet propulsion systems utilize high-velocity water jets expelled from the vessel to generate thrust, providing superior maneuverability and shallow draft capabilities compared to traditional screw propellers. Screw propellers rely on spinning blades to convert rotational energy into forward motion, offering efficient thrust in deeper waters but limited agility in tight spaces. Marine propulsion system selection often depends on vessel type, operating environment, and performance requirements, with waterjets favored for high-speed crafts and screw propellers common in cargo and passenger ships.

Fundamentals of Waterjet Propulsion

Waterjet propulsion operates by drawing water into a pump and expelling it through a nozzle at high velocity, generating thrust based on Newton's third law of motion. The fundamental components include an intake duct, a pump (impeller and stator), and a nozzle, which together efficiently convert mechanical energy into kinetic energy of the water jet. Compared to screw propellers, waterjets offer advantages in shallow waters, improved maneuverability, and reduced cavitation risks due to their enclosed pumping mechanism.

Fundamentals of Screw Propeller Systems

Screw propeller systems operate on the principle of converting rotational motion into thrust through helical blades, pushing water backward to propel a vessel forward with optimal efficiency. Their design emphasizes blade pitch, diameter, and number of blades to maximize hydrodynamic performance while minimizing cavitation and vibration. In contrast to waterjet propulsion, screw propellers are typically more efficient at lower speeds and provide better thrust at varying load conditions.

Efficiency Comparison: Waterjet vs Screw Propeller

Waterjet propulsion offers higher efficiency at high speeds and shallow waters by reducing drag and preventing cavitation compared to screw propellers. Screw propellers excel in fuel efficiency and thrust at lower speeds and are more effective for heavy vessels operating in deep waters. Overall, waterjets optimize performance in maneuverability and speed, while screw propellers dominate in energy efficiency for conventional marine operations.

Maneuverability and Control Analysis

Waterjet propulsion offers superior maneuverability compared to screw propellers due to its ability to produce rapid thrust vectoring and reverse thrust capabilities, enabling tighter turns and more precise control in confined waters. Screw propellers rely on rotating blades that generate forward thrust but often have delayed response times during direction changes and limited reverse thrust efficiency. The waterjet system's reduced risk of cavitation and minimal underwater appendages enhance vessel stability and responsiveness, making it ideal for applications requiring high agility and control.

Operational Environments and Vessel Suitability

Waterjet propulsion excels in shallow, debris-laden waters and environments requiring high maneuverability due to its ability to minimize underwater appendages and reduce the risk of damage. Screw propellers perform efficiently in deep, open waters where higher thrust and fuel economy are essential for larger vessels such as cargo ships and tankers. Vessels like fast ferries, rescue boats, and military crafts benefit from waterjet systems for rapid acceleration and tight turns, while traditional propellers remain preferred for bulk carriers and container ships operating in stable, deep-sea conditions.

Maintenance and Lifecycle Considerations

Waterjet propulsion systems typically require less frequent maintenance than screw propellers due to fewer exposed moving parts and the absence of cavitation damage on blades. The lifecycle of waterjets can be extended by regular inspection of wear rings and impellers, reducing downtime and operational costs in harsh environments. In contrast, screw propellers often incur higher maintenance expenses from blade repairs and corrosion, shortening their effective lifespan in corrosive or debris-filled waters.

Performance at Different Speeds

Waterjet propulsion delivers superior acceleration and high-speed maneuverability, excelling in vessels operating above 25 knots by minimizing cavitation and drag. Screw propellers outperform waterjets at lower speeds, typically under 15 knots, providing greater thrust efficiency and fuel economy. Hybrid systems combining both technologies optimize performance across a broad speed range, balancing speed, control, and energy consumption.

Environmental Impact: Emissions and Noise

Waterjet propulsion significantly reduces underwater noise pollution compared to traditional screw propellers, benefiting marine wildlife by minimizing acoustic disturbance. This technology also tends to improve fuel efficiency at high speeds, resulting in lower greenhouse gas emissions per nautical mile. Conversely, screw propellers generate higher levels of cavitation noise and vibration, contributing to both acoustic interference and increased fuel consumption.

Future Trends in Marine Propulsion Technologies

Waterjet propulsion is gaining momentum in high-speed marine applications due to its enhanced maneuverability, reduced cavitation, and lower maintenance compared to traditional screw propellers. Advances in computational fluid dynamics (CFD) and materials engineering are driving the development of more efficient waterjet designs that maximize thrust and fuel efficiency while minimizing environmental impact. Future trends emphasize hybrid propulsion systems integrating waterjets with electric drives to meet stringent emission regulations and optimize performance across diverse operational profiles.

Thrust efficiency

Waterjet propulsion offers higher thrust efficiency at high speeds and shallow waters compared to screw propellers, which perform better at lower speeds and deep waters.

Cavitation performance

Waterjet propulsion significantly reduces cavitation compared to screw propellers by minimizing pressure differentials and turbulence around the propulsion unit, enhancing efficiency and reducing noise.

Wake field interaction

Waterjet propulsion generates a more uniform and lower wake field interaction compared to screw propellers, reducing cavitation and improving vessel stealth and efficiency.

Bollard pull

Waterjet propulsion typically delivers lower bollard pull compared to screw propellers due to reduced thrust efficiency at low speeds.

Nozzle design

Waterjet propulsion offers enhanced maneuverability and reduced cavitation through advanced nozzle designs featuring adjustable throat geometries and flow-directing vanes, contrasting with the fixed blade geometry of screw propellers.

Impeller blade geometry

Waterjet propulsion features curved, high-speed impeller blade geometry optimized for rapid water acceleration and minimal cavitation, while screw propellers utilize twisted, helical blades designed for continuous thrust and efficient energy transfer at lower rotational speeds.

Axial flow dynamics

Waterjet propulsion generates higher axial flow velocity with reduced cavitation risk compared to traditional screw propellers, enhancing maneuverability and efficiency in high-speed marine vessels.

Maneuvering response

Waterjet propulsion offers superior maneuvering response with faster directional changes and enhanced agility compared to traditional screw propellers due to its ability to vector thrust and reduced cavitation effects.

Shallow draft operation

Waterjet propulsion offers superior shallow draft operation compared to screw propellers by minimizing underwater appendage depth and reducing the risk of damage from debris or grounding.

Propulsor noise signature

Waterjet propulsion produces significantly lower noise signatures compared to screw propellers, making it ideal for stealth and marine wildlife protection applications.

waterjet propulsion vs screw propeller Infographic

njnir.com

njnir.com