Ballast water treatment systems are designed to remove or neutralize invasive marine organisms and pollutants from seawater before discharge, ensuring compliance with environmental regulations and protecting marine ecosystems. Freshwater generators on ships produce potable water by desalinating seawater, supporting crew needs without relying on external water supplies. While both systems handle seawater, ballast water treatment prioritizes ecological safety, whereas freshwater generators focus on providing reliable drinking water for onboard use.

Table of Comparison

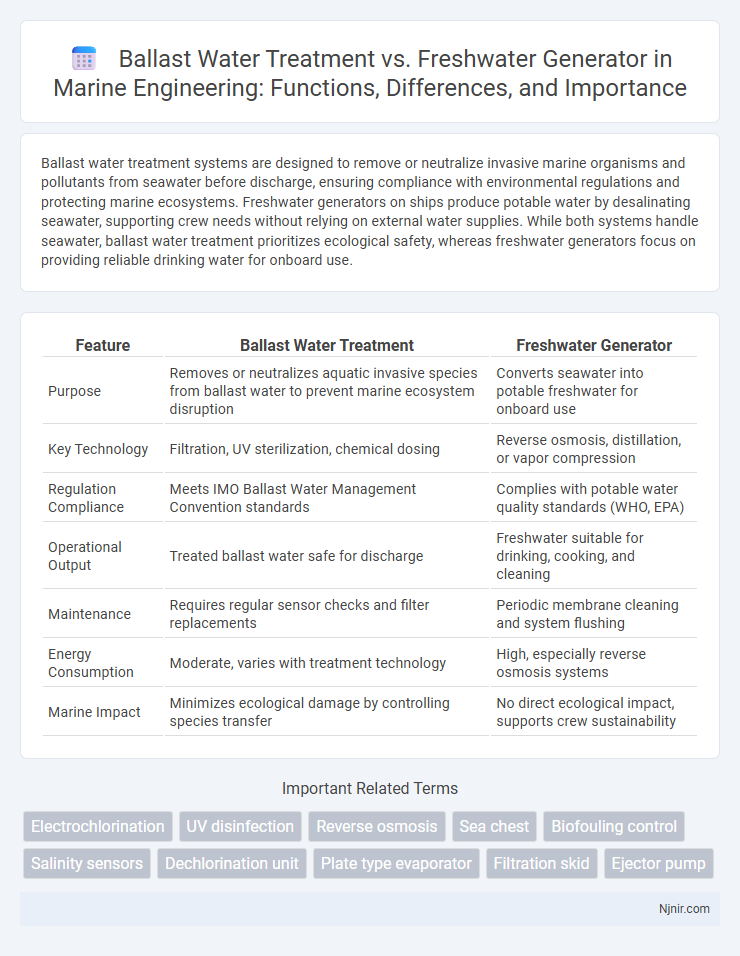

| Feature | Ballast Water Treatment | Freshwater Generator |

|---|---|---|

| Purpose | Removes or neutralizes aquatic invasive species from ballast water to prevent marine ecosystem disruption | Converts seawater into potable freshwater for onboard use |

| Key Technology | Filtration, UV sterilization, chemical dosing | Reverse osmosis, distillation, or vapor compression |

| Regulation Compliance | Meets IMO Ballast Water Management Convention standards | Complies with potable water quality standards (WHO, EPA) |

| Operational Output | Treated ballast water safe for discharge | Freshwater suitable for drinking, cooking, and cleaning |

| Maintenance | Requires regular sensor checks and filter replacements | Periodic membrane cleaning and system flushing |

| Energy Consumption | Moderate, varies with treatment technology | High, especially reverse osmosis systems |

| Marine Impact | Minimizes ecological damage by controlling species transfer | No direct ecological impact, supports crew sustainability |

Introduction to Ballast Water Treatment and Freshwater Generators

Ballast water treatment systems are essential for managing and disinfecting ballast water on ships to prevent the spread of invasive aquatic species, complying with the International Maritime Organization's Ballast Water Management Convention. Freshwater generators, also known as desalination units, convert seawater into potable water through processes like reverse osmosis or distillation, ensuring a reliable supply of fresh water for crew consumption and operational needs. Both systems play critical roles in marine vessel sustainability by addressing environmental protection and crew welfare through specialized water management technologies.

Key Functions in Marine Vessels

Ballast water treatment systems eliminate harmful aquatic organisms and pathogens from seawater used for vessel stability, ensuring compliance with environmental regulations and preventing ecological contamination. Freshwater generators produce potable water by desalinating seawater, supplying essential freshwater for crew consumption, cooking, and cleaning during voyages. Both systems are critical to operational efficiency and safety, with ballast water treatment focused on environmental protection and freshwater generators emphasizing resource sustainability on marine vessels.

Ballast Water Treatment: Purpose and Methods

Ballast water treatment systems are designed to prevent the spread of invasive aquatic species by removing or neutralizing microorganisms and sediments in ballast water before discharge. Common methods include filtration, ultraviolet (UV) irradiation, chemical biocides, and deoxygenation processes to ensure compliance with the International Maritime Organization's Ballast Water Management Convention. These treatments are critical for environmental protection and maintaining marine biodiversity, distinguishing them from freshwater generators that primarily produce potable water through distillation or reverse osmosis.

Freshwater Generators: Role and Operation

Freshwater generators convert seawater into potable water using processes such as reverse osmosis or distillation, essential for providing safe drinking water onboard ships. These systems operate by removing salts, microorganisms, and impurities to ensure compliance with maritime water quality standards. Efficient freshwater generation supports crew hydration, engine cooling, and overall ship maintenance, distinguishing their role from ballast water treatment systems, which focus on ecological management by removing invasive species from ballast tanks.

Environmental Compliance and Regulations

Ballast water treatment systems are critical for meeting the International Maritime Organization's Ballast Water Management Convention, aimed at preventing the spread of invasive aquatic species by treating and disinfecting ballast water before discharge. Freshwater generators on ships primarily focus on producing potable water and adhere to health and safety standards but are not regulated under environmental treaties like those governing ballast water treatment. Compliance with ballast water regulations requires advanced filtration and biocide technologies, whereas freshwater generators must meet standards for water quality without specific environmental discharge restrictions.

Technological Advances in Ballast Water Management

Technological advances in ballast water management have led to the development of sophisticated treatment systems that use filtration, ultraviolet (UV) irradiation, and advanced oxidation processes to effectively eliminate invasive aquatic species and pathogens from ballast water. Unlike freshwater generators that primarily focus on desalination and water purification for onboard use, modern ballast water treatment systems are designed to comply with stringent International Maritime Organization (IMO) regulations to prevent environmental contamination. Innovations such as real-time monitoring, chemical-free disinfection, and energy-efficient equipment have significantly improved the reliability and sustainability of ballast water management solutions on commercial vessels.

Efficiency and Energy Consumption Comparison

Ballast water treatment systems and freshwater generators differ significantly in efficiency and energy consumption; ballast water treatment typically focuses on removing invasive species, requiring energy-intensive filtration and UV radiation processes that can consume between 10 to 50 kWh per 1000 cubic meters of water treated. Freshwater generators, especially those using reverse osmosis or distillation, convert seawater to potable water with energy consumption often ranging from 2 to 6 kWh per cubic meter, demonstrating higher energy efficiency for water production. Evaluating operational context reveals freshwater generators generally offer lower energy consumption per unit output, while ballast water treatment prioritizes regulatory compliance over energy optimization.

Maintenance and Operational Challenges

Ballast water treatment systems require regular maintenance of filters, UV lamps, and chemical dosing components to prevent biofouling and ensure compliance with international regulations, posing complex operational challenges. Freshwater generators demand frequent monitoring of membrane integrity and scaling control to maintain efficient desalination performance, often facing issues related to seawater temperature and salinity variations. Both systems necessitate specialized crew training and preventive maintenance schedules to minimize downtime and extend equipment lifespan in marine environments.

Cost Implications for Shipowners

Ballast water treatment systems incur higher upfront installation costs compared to freshwater generators, due to complex filtering and disinfection technologies required to meet IMO regulations. Operating expenses for ballast water treatment include energy consumption, chemical usage, and regular maintenance, which can significantly impact long-term operational budgets. Freshwater generators, while maintaining lower initial costs, may involve consistent energy usage and maintenance, but generally present lower overall expenses than ballast water treatment solutions for shipowners.

Future Trends in Marine Water Treatment Solutions

Future trends in marine water treatment solutions emphasize advanced technologies like membrane filtration, UV disinfection, and electrochlorination for both ballast water treatment and freshwater generation. Integration of AI-driven monitoring systems enables real-time optimization of water quality and energy efficiency on vessels. Sustainable practices and stricter International Maritime Organization (IMO) regulations drive innovation toward eco-friendly, low-maintenance marine water treatment systems.

Electrochlorination

Electrochlorination efficiently treats ballast water by producing disinfectant chlorine on-site, while freshwater generators primarily focus on producing potable water without integrated disinfection capabilities.

UV disinfection

UV disinfection in ballast water treatment effectively eliminates marine pathogens to prevent invasive species transfer, while freshwater generators use UV technology primarily to ensure potable water safety by removing microbial contaminants.

Reverse osmosis

Reverse osmosis in ballast water treatment effectively removes contaminants and invasive species, while in freshwater generators it efficiently produces potable water by desalinating seawater.

Sea chest

Sea chests play a critical role in ballast water treatment by serving as intake points for seawater used in treatment systems, while freshwater generators rely on separate intake mechanisms, highlighting the sea chest's unique importance in managing marine water quality and ship operations.

Biofouling control

Ballast water treatment systems primarily prevent biofouling by eliminating invasive aquatic organisms, while freshwater generators reduce biofouling risks by supplying clean desalinated water that limits microbial growth in ship systems.

Salinity sensors

Salinity sensors in ballast water treatment systems ensure compliance with environmental regulations by monitoring and managing salt concentrations, while freshwater generators use these sensors to optimize freshwater production by accurately measuring and adjusting salinity levels.

Dechlorination unit

The dechlorination unit in ballast water treatment systems effectively neutralizes chlorine to protect marine ecosystems, whereas freshwater generators typically lack this component because they produce potable water without using chlorination processes.

Plate type evaporator

Plate type evaporators in ballast water treatment systems efficiently separate contaminants by phase change, whereas freshwater generators use similar plate heat exchanger technology primarily to produce potable water from seawater through evaporation and condensation.

Filtration skid

Filtration skids in ballast water treatment systems use advanced filtration membranes and automatic backwash mechanisms to remove invasive species, whereas freshwater generator filtration skids primarily focus on removing salt, sediments, and impurities to produce potable water.

Ejector pump

Ejector pumps in ballast water treatment systems efficiently manage water flow using steam or compressed air, contrasting with freshwater generators that rely on ejectors primarily to create vacuum for distillation processes.

Ballast water treatment vs Freshwater generator Infographic

njnir.com

njnir.com