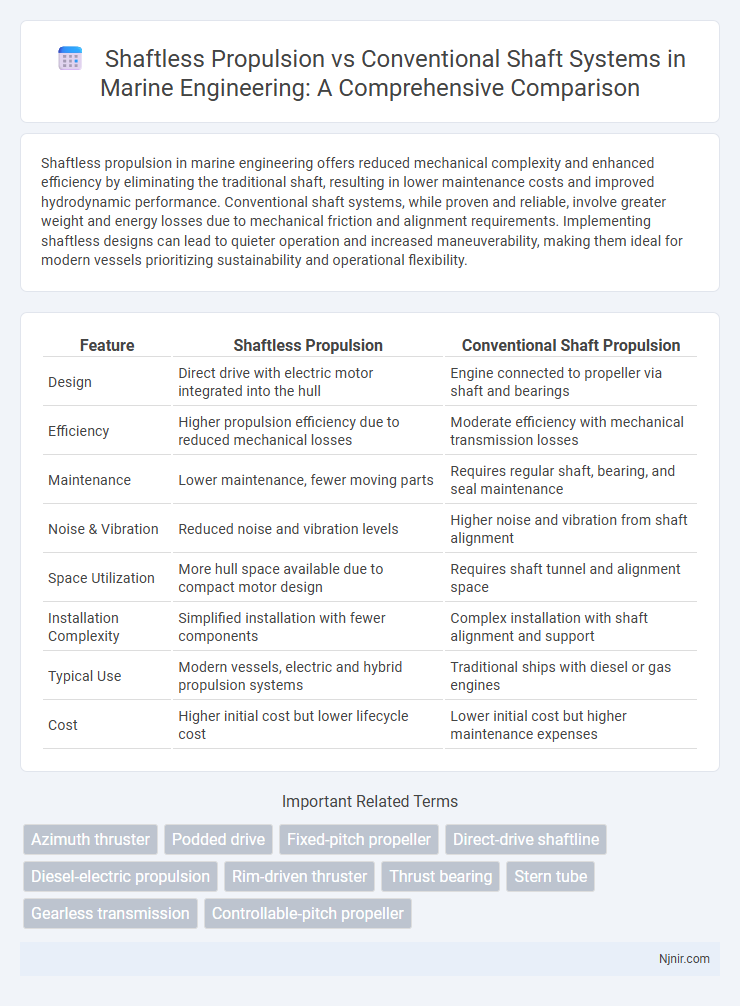

Shaftless propulsion in marine engineering offers reduced mechanical complexity and enhanced efficiency by eliminating the traditional shaft, resulting in lower maintenance costs and improved hydrodynamic performance. Conventional shaft systems, while proven and reliable, involve greater weight and energy losses due to mechanical friction and alignment requirements. Implementing shaftless designs can lead to quieter operation and increased maneuverability, making them ideal for modern vessels prioritizing sustainability and operational flexibility.

Table of Comparison

| Feature | Shaftless Propulsion | Conventional Shaft Propulsion |

|---|---|---|

| Design | Direct drive with electric motor integrated into the hull | Engine connected to propeller via shaft and bearings |

| Efficiency | Higher propulsion efficiency due to reduced mechanical losses | Moderate efficiency with mechanical transmission losses |

| Maintenance | Lower maintenance, fewer moving parts | Requires regular shaft, bearing, and seal maintenance |

| Noise & Vibration | Reduced noise and vibration levels | Higher noise and vibration from shaft alignment |

| Space Utilization | More hull space available due to compact motor design | Requires shaft tunnel and alignment space |

| Installation Complexity | Simplified installation with fewer components | Complex installation with shaft alignment and support |

| Typical Use | Modern vessels, electric and hybrid propulsion systems | Traditional ships with diesel or gas engines |

| Cost | Higher initial cost but lower lifecycle cost | Lower initial cost but higher maintenance expenses |

Introduction to Shaftless and Conventional Shaft Propulsion

Shaftless propulsion systems eliminate the need for a traditional propeller shaft, utilizing direct drive or rim-driven thrusters for enhanced efficiency and reduced mechanical complexity. Conventional shaft propulsion relies on a rotating shaft connected to an engine or motor, transmitting power to the propeller for vessel movement. This fundamental difference influences maintenance demands, energy loss, and spatial design within marine engineering applications.

Key Design Differences: Shaftless vs Conventional Systems

Shaftless propulsion employs electric motors integrated directly into the vessel's hull, eliminating the traditional propeller shaft and reducing mechanical losses, noise, and vibration. Conventional shaft systems rely on a longitudinal shaft connecting the engine to the propeller, requiring bearings, seals, and alignment, which increase maintenance complexity and potential energy loss. The shaftless design allows for more flexible hull configurations and improved maneuverability, while conventional shafts provide proven reliability and easier retrofit options for existing vessels.

Advantages of Shaftless Propulsion in Marine Engineering

Shaftless propulsion in marine engineering offers enhanced maneuverability and reduced mechanical losses compared to conventional shaft systems, leading to improved fuel efficiency and lower maintenance costs. By eliminating the traditional shaft and gearbox, shaftless propulsion reduces vibration and noise, enhancing onboard comfort and structural integrity. This system also allows for more flexible vessel design, optimizing space utilization and enabling installation in smaller or unconventional hull forms.

Operational Efficiency Comparison

Shaftless propulsion systems eliminate the mechanical losses associated with conventional shaft bearings and seals, resulting in higher energy efficiency and reduced maintenance requirements. By directly integrating the motor with the propeller or impeller, shaftless designs minimize vibration and improve torque transmission, enhancing overall operational reliability. Conventional shaft systems, while well-established, often incur greater frictional losses and require periodic lubrication, which can decrease efficiency over time.

Maintenance Requirements and Lifecycle Costs

Shaftless propulsion systems eliminate the need for a traditional shaft, significantly reducing maintenance requirements by minimizing wear points and lowering the risk of shaft-related failures. Conventional shaft propulsion demands regular inspections, alignment, lubrication, and potential shaft replacement, leading to higher operational downtime and maintenance expenses. Over the lifecycle, shaftless propulsion typically offers reduced total cost of ownership due to decreased maintenance interventions and extended component longevity.

Impact on Vessel Maneuverability and Performance

Shaftless propulsion systems significantly enhance vessel maneuverability by allowing independent control of multiple propellers, resulting in improved precision during docking and tight navigation scenarios. These systems reduce mechanical complexity and drag associated with conventional shafts, boosting overall propulsion efficiency and fuel economy. Conventional shaft setups, while robust, offer less agility due to fixed propeller alignment and increased hydrodynamic resistance, limiting vessel responsiveness and performance in dynamic marine environments.

Energy Consumption and Environmental Considerations

Shaftless propulsion systems reduce energy consumption by eliminating mechanical losses associated with conventional shafts, resulting in higher propulsion efficiency and lower fuel usage. These systems also minimize underwater noise and vibration, enhancing marine biodiversity protection compared to traditional shaft-driven vessels. Reduced emissions from optimized energy use further contribute to environmental sustainability, making shaftless propulsion a cleaner alternative.

Installation Challenges and Space Optimization

Shaftless propulsion systems eliminate the need for long drive shafts, significantly reducing hull penetration and simplifying installation, especially in compact vessels. This design optimizes internal space by freeing up areas traditionally occupied by shaft tunnels, allowing for more efficient cabin layouts or additional storage. Conventional shaft propulsion requires precise alignment and sturdy bearing supports, often complicating installation and consuming valuable internal volume.

Reliability and Safety Considerations

Shaftless propulsion systems reduce mechanical complexity by eliminating traditional drive shafts, leading to fewer moving parts and lower risks of mechanical failure. This design enhances reliability by minimizing wear and tear, reducing maintenance intervals, and improving operational uptime. From a safety perspective, shaftless propulsion also lowers the likelihood of catastrophic shaft-related failures and decreases vibration and noise levels, contributing to safer and more stable vessel operation.

Future Trends in Marine Propulsion Technologies

Shaftless propulsion systems, which eliminate traditional shaftlines and bearings, offer enhanced efficiency, reduced maintenance, and improved maneuverability compared to conventional shaft-driven setups. Future trends emphasize integrating electric drives with shaftless designs to support hybrid and fully electric vessels, enabling lower emissions and increased operational flexibility. Advances in materials and power electronics further boost the performance and adoption of shaftless propulsion as the maritime industry moves towards sustainable, eco-friendly marine technologies.

Azimuth thruster

Azimuth thrusters provide enhanced maneuverability and efficiency by eliminating the conventional shaft, enabling 360-degree rotation and precise vessel control compared to traditional fixed-shaft propulsion systems.

Podded drive

Podded drive shaftless propulsion enhances maneuverability and efficiency by integrating electric motors directly into the propeller units, eliminating the conventional shaft system and reducing mechanical losses.

Fixed-pitch propeller

Shaftless propulsion with fixed-pitch propellers reduces mechanical complexity and maintenance compared to conventional shaft systems while maintaining efficient thrust delivery.

Direct-drive shaftline

Direct-drive shaftline systems in shaftless propulsion eliminate mechanical shafts, enhancing efficiency, reducing maintenance, and improving vessel maneuverability compared to conventional shaft-driven propulsion.

Diesel-electric propulsion

Diesel-electric propulsion with shaftless designs enhances maneuverability and reduces mechanical losses compared to conventional shaft-driven systems by eliminating the need for long shafts and complex gearboxes.

Rim-driven thruster

Rim-driven thrusters eliminate the need for a central shaft by integrating the electric motor within the propeller rim, enhancing efficiency and reducing noise compared to conventional shaft-based propulsion systems.

Thrust bearing

Shaftless propulsion eliminates the need for a traditional thrust bearing by integrating the propeller directly onto the motor shaft, reducing mechanical complexity and maintenance compared to conventional shaft systems that rely on thrust bearings to absorb axial loads.

Stern tube

Shaftless propulsion eliminates the conventional stern tube, reducing maintenance and leakage risks by using integrated electric motors instead of traditional shaft-driven systems.

Gearless transmission

Gearless transmission in shaftless propulsion systems reduces mechanical losses and maintenance by eliminating gears and shafts, enhancing efficiency compared to conventional shaft-based propulsion.

Controllable-pitch propeller

Shaftless propulsion systems integrated with controllable-pitch propellers offer enhanced maneuverability, reduced vibration, and improved fuel efficiency compared to conventional shaft-driven setups.

shaftless propulsion vs conventional shaft Infographic

njnir.com

njnir.com