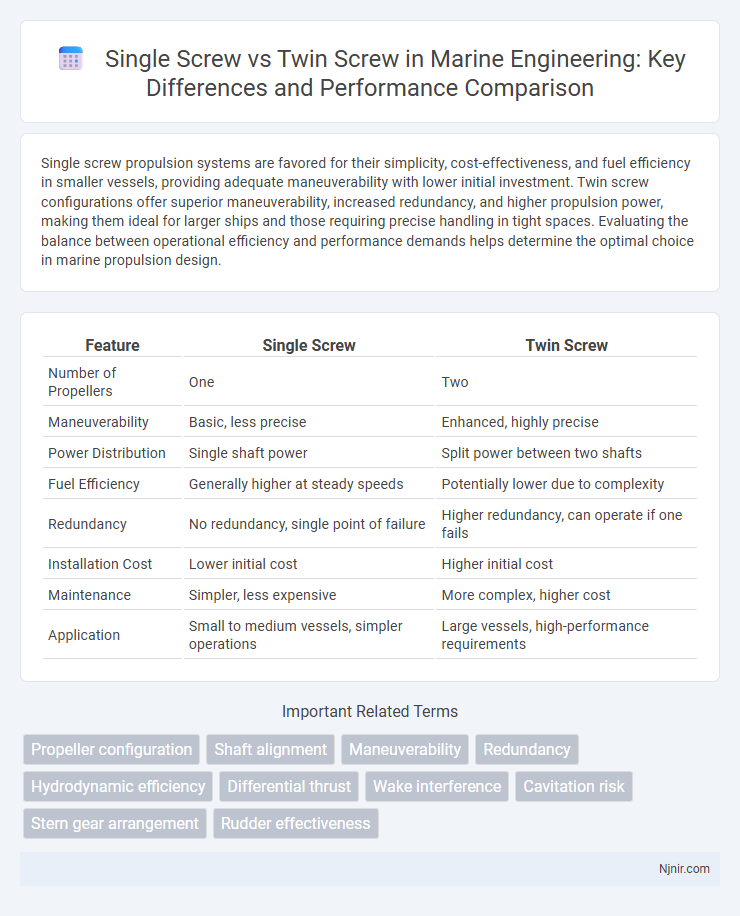

Single screw propulsion systems are favored for their simplicity, cost-effectiveness, and fuel efficiency in smaller vessels, providing adequate maneuverability with lower initial investment. Twin screw configurations offer superior maneuverability, increased redundancy, and higher propulsion power, making them ideal for larger ships and those requiring precise handling in tight spaces. Evaluating the balance between operational efficiency and performance demands helps determine the optimal choice in marine propulsion design.

Table of Comparison

| Feature | Single Screw | Twin Screw |

|---|---|---|

| Number of Propellers | One | Two |

| Maneuverability | Basic, less precise | Enhanced, highly precise |

| Power Distribution | Single shaft power | Split power between two shafts |

| Fuel Efficiency | Generally higher at steady speeds | Potentially lower due to complexity |

| Redundancy | No redundancy, single point of failure | Higher redundancy, can operate if one fails |

| Installation Cost | Lower initial cost | Higher initial cost |

| Maintenance | Simpler, less expensive | More complex, higher cost |

| Application | Small to medium vessels, simpler operations | Large vessels, high-performance requirements |

Introduction to Marine Propulsion Systems

Single screw marine propulsion systems utilize one propeller connected to the engine, offering simplicity and cost-effectiveness ideal for smaller vessels or moderate speed requirements. Twin screw systems employ two propellers driven by separate engines or shafts, enhancing maneuverability, redundancy, and power distribution for larger ships and complex navigation scenarios. The choice between single and twin screw configurations significantly impacts vessel performance, fuel efficiency, and operational reliability in marine propulsion.

Overview of Single Screw Propulsion

Single screw propulsion systems utilize a single propeller connected to the engine for thrust, offering simplicity, lower initial costs, and reduced maintenance compared to twin screw configurations. This propulsion type provides efficient fuel consumption and is commonly found in smaller vessels, commercial ships, and certain types of cargo carriers. Single screw setups typically deliver adequate maneuverability and performance for many applications, despite twin screw systems being favored for enhanced redundancy and improved handling in larger or specialized vessels.

Overview of Twin Screw Propulsion

Twin screw propulsion systems utilize two propellers mounted on separate shafts, providing enhanced maneuverability and redundancy compared to single screw configurations. These systems offer improved handling characteristics and increased power distribution, making them ideal for vessels requiring superior control and reliability. Twin screw propulsion also allows for better efficiency in varying operational conditions, often resulting in optimized fuel consumption and performance.

Efficiency Comparison: Single vs Twin Screw

Single screw extruders offer moderate efficiency in processing low to medium viscosity materials, characterized by simpler design and lower energy consumption. Twin screw extruders excel in efficiency when handling high-viscosity polymers and complex compounding, providing superior mixing, heat transfer, and consistent output. Industrial applications typically favor twin screw systems for enhanced productivity and precise material control despite higher initial costs.

Maneuverability and Handling Differences

Single screw vessels offer straightforward handling with simpler steering mechanisms, providing predictable maneuverability at moderate speeds. Twin screw vessels feature dual propellers, enabling enhanced control through independent thrust adjustments, resulting in tighter turning radii and superior responsiveness in confined waters. This makes twin screw systems preferred for operations requiring precise docking and complex maneuvers.

Installation and Maintenance Considerations

Single screw extruders offer simpler installation processes due to fewer components and a more straightforward design, reducing initial setup time and costs. Maintenance for single screw machines is generally less complex, involving routine checks on the screw, barrel, and drive system with easily accessible parts. Twin screw extruders require precise alignment and more detailed installation to ensure synchronization between screws, while maintenance demands regular inspection of intermeshing elements for wear and lubrication, increasing overall operational upkeep.

Cost Implications and Fuel Consumption

Single screw ships generally have lower initial construction and maintenance costs compared to twin screw vessels due to simpler propulsion systems and fewer components. Fuel consumption for single screw ships tends to be more efficient at cruising speeds since they have less drag and reduced mechanical complexity, leading to cost savings over time. However, twin screw ships offer better maneuverability and redundancy, which can result in operational efficiencies that offset their higher fuel and maintenance expenses in certain operational profiles.

Suitability for Different Vessel Types

Single screw propulsion suits smaller vessels such as fishing boats and coastal barges, offering simplicity and cost-effectiveness. Twin screw systems excel in larger ships like ferries, tankers, and offshore vessels, providing enhanced maneuverability and redundancy. The choice depends on vessel size, operational requirements, and the need for precise handling in confined or demanding environments.

Reliability and Redundancy in Propulsion

Single screw propulsion systems offer simplicity and cost-effectiveness but have limited redundancy, making them more vulnerable to propulsion failure. Twin screw configurations enhance reliability by providing two independent propellers, ensuring continued operation if one fails. This redundancy significantly improves vessel safety and maneuverability, essential for critical maritime operations.

Future Trends in Marine Propeller Technology

Future trends in marine propeller technology emphasize increased efficiency and reduced environmental impact, favoring twin screw systems for their superior maneuverability and fuel savings in large vessels. Advances in computational fluid dynamics (CFD) and materials science are driving innovations in propeller blade design, optimizing both single and twin screw configurations for noise reduction and vibration control. Integration of hybrid and electric propulsion technologies further accelerates the evolution of twin screw setups, enhancing performance and adaptability in next-generation marine vessels.

Propeller configuration

Single screw propellers offer simpler design with lower cost and maintenance, while twin screw propellers provide enhanced maneuverability, greater thrust efficiency, and improved vessel stability.

Shaft alignment

Twin screw extruders provide superior shaft alignment and reduced vibration compared to single screw extruders, enhancing mechanical stability and operational efficiency.

Maneuverability

Twin screw vessels offer superior maneuverability compared to single screw vessels due to independent control of two propellers enabling tighter turns and enhanced precision.

Redundancy

Twin screw systems provide enhanced redundancy by maintaining operation if one screw fails, unlike single screw systems which experience complete failure.

Hydrodynamic efficiency

Twin screw compressors demonstrate higher hydrodynamic efficiency than single screw compressors due to reduced internal leakage and improved fluid dynamics within the meshing rotors.

Differential thrust

Twin screw propulsion systems significantly reduce differential thrust compared to single screw setups, enhancing vessel stability and maneuverability during asymmetric engine operation.

Wake interference

Twin screw configurations minimize wake interference more effectively than single screw setups by distributing propulsion forces and reducing turbulent flow between propellers.

Cavitation risk

Twin screw pumps typically exhibit lower cavitation risk than single screw pumps due to their continuous, balanced flow and reduced pressure pulsations.

Stern gear arrangement

Twin screw stern gear arrangements provide enhanced thrust efficiency and maneuverability compared to single screw configurations by distributing power across two independently controlled propellers.

Rudder effectiveness

Twin screw systems enhance rudder effectiveness by providing improved maneuverability and reduced turning radius compared to single screw configurations.

single screw vs twin screw Infographic

njnir.com

njnir.com