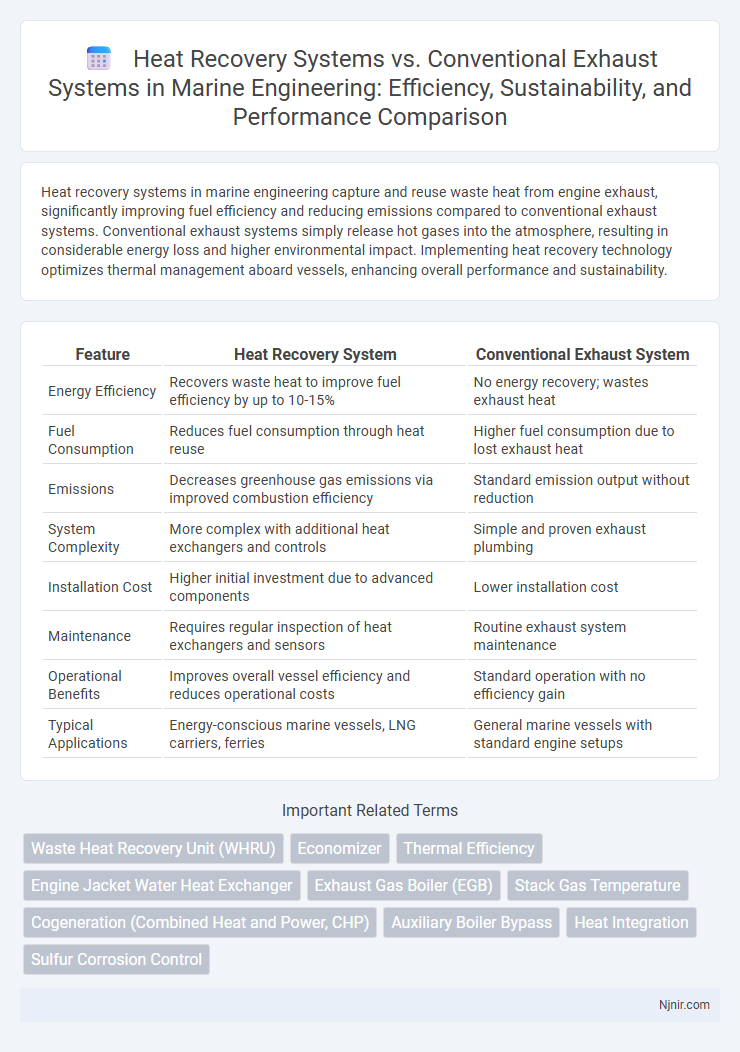

Heat recovery systems in marine engineering capture and reuse waste heat from engine exhaust, significantly improving fuel efficiency and reducing emissions compared to conventional exhaust systems. Conventional exhaust systems simply release hot gases into the atmosphere, resulting in considerable energy loss and higher environmental impact. Implementing heat recovery technology optimizes thermal management aboard vessels, enhancing overall performance and sustainability.

Table of Comparison

| Feature | Heat Recovery System | Conventional Exhaust System |

|---|---|---|

| Energy Efficiency | Recovers waste heat to improve fuel efficiency by up to 10-15% | No energy recovery; wastes exhaust heat |

| Fuel Consumption | Reduces fuel consumption through heat reuse | Higher fuel consumption due to lost exhaust heat |

| Emissions | Decreases greenhouse gas emissions via improved combustion efficiency | Standard emission output without reduction |

| System Complexity | More complex with additional heat exchangers and controls | Simple and proven exhaust plumbing |

| Installation Cost | Higher initial investment due to advanced components | Lower installation cost |

| Maintenance | Requires regular inspection of heat exchangers and sensors | Routine exhaust system maintenance |

| Operational Benefits | Improves overall vessel efficiency and reduces operational costs | Standard operation with no efficiency gain |

| Typical Applications | Energy-conscious marine vessels, LNG carriers, ferries | General marine vessels with standard engine setups |

Introduction to Marine Exhaust Systems

Marine exhaust systems are crucial for safely expelling engine gases while maintaining vessel performance and environmental compliance. Heat recovery systems enhance traditional exhaust setups by capturing and reusing thermal energy, improving fuel efficiency and reducing emissions. Conventional exhaust systems primarily focus on removing exhaust gases without energy recapture, often resulting in higher fuel consumption and increased environmental impact.

Fundamental Principles of Heat Recovery in Marine Engineering

Heat recovery systems in marine engineering utilize exhaust gases' thermal energy to improve fuel efficiency by converting waste heat into usable power, typically through steam turbines or economizers. Conventional exhaust systems simply expel hot gases, losing significant energy that could otherwise reduce fuel consumption and emissions. Integrating heat recovery enhances overall propulsion efficiency, lowers operational costs, and supports environmental regulations by recovering heat from engine exhaust.

Conventional Exhaust System: An Overview

The conventional exhaust system primarily functions to expel combustion gases from an engine, facilitating efficient operation and preventing harmful gas buildup. It includes components such as the exhaust manifold, catalytic converter, muffler, and tailpipe, designed to reduce noise and toxic emissions. Unlike heat recovery systems, conventional exhaust systems do not capture or reuse waste heat, resulting in energy loss and lower overall fuel efficiency.

Comparative Energy Efficiency: Heat Recovery vs Conventional Exhaust

Heat recovery systems capture waste heat from exhaust gases to preheat incoming air or water, significantly reducing energy consumption and enhancing overall system efficiency. Conventional exhaust systems release hot air directly outside, resulting in substantial energy loss and higher operational costs. By integrating heat recovery technology, buildings can achieve energy savings up to 30% compared to traditional exhaust setups.

Environmental Impact and Emission Reduction

Heat recovery systems significantly reduce environmental impact by capturing and reusing waste heat from exhaust gases, leading to lower fuel consumption and decreased greenhouse gas emissions compared to conventional exhaust systems. These systems enhance overall energy efficiency, resulting in reduced CO2, NOx, and particulate matter release into the atmosphere. Conventional exhaust systems, lacking heat recovery capabilities, tend to emit higher levels of pollutants and contribute more substantially to air pollution and climate change.

Operational Costs and Fuel Savings Analysis

Heat recovery systems significantly reduce operational costs by capturing and reusing waste heat, leading to substantial fuel savings compared to conventional exhaust systems. By improving thermal efficiency, these systems decrease fuel consumption by up to 20%, directly lowering energy expenses in industrial processes. The reduced fuel dependency also minimizes maintenance costs associated with exhaust emissions and enhances overall system longevity, making heat recovery systems a cost-effective alternative to traditional exhaust solutions.

Maintenance Requirements and Lifecycle Considerations

Heat recovery systems require specialized maintenance including regular inspection of heat exchangers and cleaning of filters to ensure optimal energy transfer efficiency, whereas conventional exhaust systems demand routine checks for corrosion and fan performance. The lifecycle of heat recovery systems typically extends longer due to their energy-saving design and durable components, reducing long-term operational costs compared to conventional systems. Maintenance intervals for heat recovery units are generally longer but more technical, while conventional exhaust systems incur more frequent but simpler upkeep tasks.

Space and Installation Challenges Onboard

Heat recovery systems onboard vessels require additional space due to the need for heat exchangers and associated piping, posing significant installation challenges in already compact engine rooms. In contrast, conventional exhaust systems have a simpler layout that demands less spatial accommodation, making installation more straightforward. Integrating heat recovery technology often necessitates structural modifications and careful planning to avoid interference with other machinery and ensure optimal thermal efficiency.

Real-world Applications and Case Studies

Heat recovery systems significantly enhance energy efficiency by capturing waste heat from exhaust gases in industrial settings such as power plants and manufacturing facilities, leading to reduced fuel consumption and lower operational costs. Case studies in commercial buildings demonstrate that integrating heat recovery ventilation systems can improve indoor air quality while decreasing HVAC energy use by up to 40%. Conventional exhaust systems, by contrast, primarily focus on removing pollutants and heat without reclaiming energy, resulting in higher utility expenses and greater environmental impact over time.

Future Trends in Marine Exhaust Technology

Heat recovery systems in marine exhaust technology are advancing rapidly, enabling ships to capture and reuse waste heat for energy efficiency and reduced fuel consumption. Conventional exhaust systems are gradually being replaced by integrated solutions that enhance emissions control and optimize thermal energy utilization. Future trends emphasize smart, sensor-driven heat recovery units combined with hybrid propulsion to meet stringent environmental regulations and improve overall vessel performance.

Waste Heat Recovery Unit (WHRU)

The Waste Heat Recovery Unit (WHRU) in heat recovery systems captures and repurposes exhaust heat to improve energy efficiency, unlike conventional exhaust systems that simply release waste heat into the environment.

Economizer

Heat recovery systems with economizers improve energy efficiency by capturing waste heat from exhaust gases to preheat boiler feedwater, significantly reducing fuel consumption compared to conventional exhaust systems.

Thermal Efficiency

Heat recovery systems enhance thermal efficiency by capturing and reusing waste heat, whereas conventional exhaust systems lose significant energy through expelled hot gases.

Engine Jacket Water Heat Exchanger

The Heat Recovery System using an Engine Jacket Water Heat Exchanger recovers thermal energy from engine coolant to improve fuel efficiency, while a Conventional Exhaust System dissipates heat without energy recapture.

Exhaust Gas Boiler (EGB)

Exhaust Gas Boilers (EGB) in heat recovery systems capture waste heat from exhaust gases to improve energy efficiency and reduce fuel consumption compared to conventional exhaust systems.

Stack Gas Temperature

Heat recovery systems significantly reduce stack gas temperature compared to conventional exhaust systems, enhancing energy efficiency and lowering heat loss.

Cogeneration (Combined Heat and Power, CHP)

Heat recovery systems in cogeneration (CHP) capture waste heat from conventional exhaust systems to improve overall energy efficiency by simultaneously producing electricity and usable thermal energy.

Auxiliary Boiler Bypass

A Heat Recovery System reduces fuel consumption by capturing waste heat to minimize Auxiliary Boiler Bypass usage compared to a Conventional Exhaust System.

Heat Integration

Heat recovery systems enhance energy efficiency by capturing and reusing waste heat from exhaust gases, whereas conventional exhaust systems release heat energy without integration, resulting in significant energy loss.

Sulfur Corrosion Control

Heat recovery systems reduce sulfur corrosion significantly compared to conventional exhaust systems by lowering flue gas temperatures and minimizing acidic condensate formation.

Heat recovery system vs Conventional exhaust system Infographic

njnir.com

njnir.com