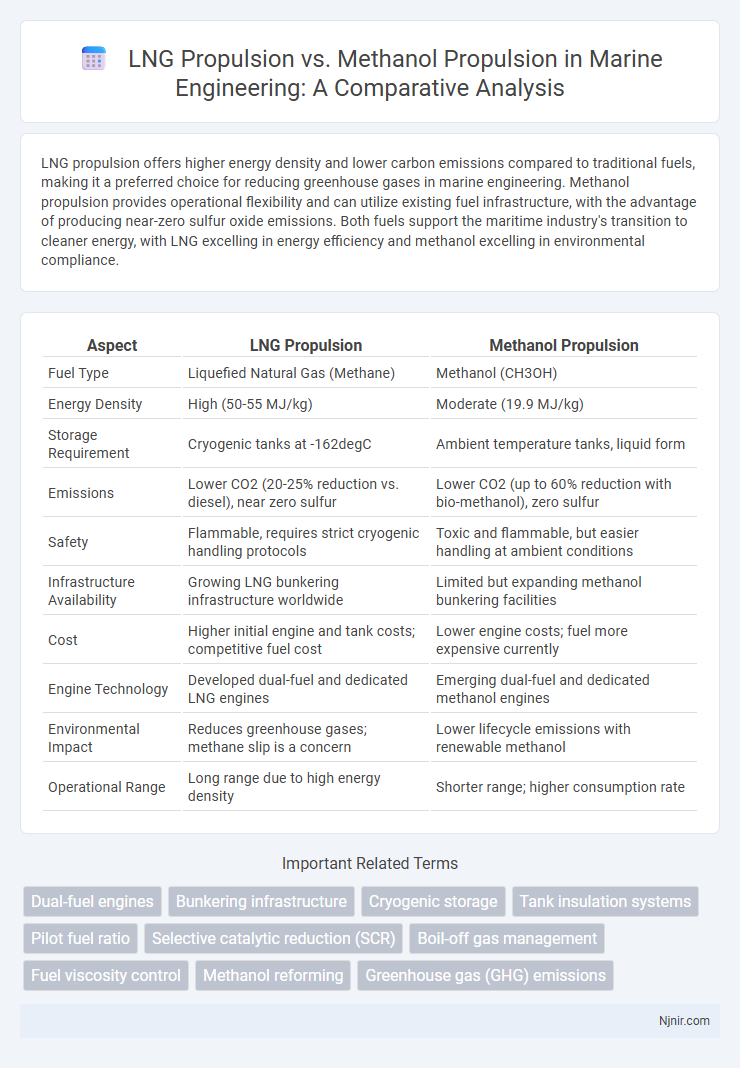

LNG propulsion offers higher energy density and lower carbon emissions compared to traditional fuels, making it a preferred choice for reducing greenhouse gases in marine engineering. Methanol propulsion provides operational flexibility and can utilize existing fuel infrastructure, with the advantage of producing near-zero sulfur oxide emissions. Both fuels support the maritime industry's transition to cleaner energy, with LNG excelling in energy efficiency and methanol excelling in environmental compliance.

Table of Comparison

| Aspect | LNG Propulsion | Methanol Propulsion |

|---|---|---|

| Fuel Type | Liquefied Natural Gas (Methane) | Methanol (CH3OH) |

| Energy Density | High (50-55 MJ/kg) | Moderate (19.9 MJ/kg) |

| Storage Requirement | Cryogenic tanks at -162degC | Ambient temperature tanks, liquid form |

| Emissions | Lower CO2 (20-25% reduction vs. diesel), near zero sulfur | Lower CO2 (up to 60% reduction with bio-methanol), zero sulfur |

| Safety | Flammable, requires strict cryogenic handling protocols | Toxic and flammable, but easier handling at ambient conditions |

| Infrastructure Availability | Growing LNG bunkering infrastructure worldwide | Limited but expanding methanol bunkering facilities |

| Cost | Higher initial engine and tank costs; competitive fuel cost | Lower engine costs; fuel more expensive currently |

| Engine Technology | Developed dual-fuel and dedicated LNG engines | Emerging dual-fuel and dedicated methanol engines |

| Environmental Impact | Reduces greenhouse gases; methane slip is a concern | Lower lifecycle emissions with renewable methanol |

| Operational Range | Long range due to high energy density | Shorter range; higher consumption rate |

Introduction to LNG and Methanol Propulsion

LNG propulsion utilizes liquefied natural gas as a cleaner alternative to traditional marine fuels, significantly reducing sulfur oxide (SOx), nitrogen oxide (NOx), and carbon dioxide (CO2) emissions. Methanol propulsion employs methanol fuel, a liquid alcohol derived from natural gas or biomass, offering lower greenhouse gas emissions and compatibility with existing marine engines. Both propulsion systems are gaining traction in the maritime industry for their environmental benefits and regulatory compliance with IMO 2020 and future emission standards.

Fuel Characteristics and Availability

LNG propulsion offers high energy density with lower carbon emissions and sulfur content compared to conventional marine fuels, making it an attractive option for reducing environmental impact. Methanol, with its liquid state at ambient temperature and ease of storage, presents advantages in handling and wide availability from renewable sources, enabling more sustainable operations. While LNG infrastructure is expanding primarily in major ports, methanol benefits from existing liquid fuel supply chains, supporting flexible and global refueling options.

Environmental Impact and Emission Profiles

LNG propulsion significantly reduces sulfur oxides (SOx) and nitrogen oxides (NOx) emissions compared to traditional marine fuels, contributing to lower greenhouse gas (GHG) emissions and compliance with IMO 2020 sulfur cap regulations. Methanol propulsion offers even lower particulate matter (PM) and virtually zero sulfur emissions, along with carbon-neutral potential when produced from renewable sources, making it a promising alternative for decarbonizing maritime transport. Both fuels improve air quality, but methanol's ability to reduce lifecycle CO2 emissions positions it as a more sustainable solution for long-term environmental impact reduction.

Energy Efficiency and Performance

LNG propulsion offers higher energy density and lower carbon emissions compared to methanol, resulting in improved fuel efficiency and extended vessel range. Methanol propulsion provides easier storage and handling due to its liquid state at ambient temperature, with faster refueling times but generally lower energy content per volume than LNG. Performance-wise, LNG engines deliver better thermal efficiency and power output, while methanol engines benefit from reduced particulate emissions and compatibility with existing diesel engine technology.

Engine Technology and Modifications

LNG propulsion engines utilize high-pressure gas injection and cryogenic fuel storage systems requiring advanced insulation and fuel handling modifications, enhancing fuel efficiency and reducing emissions. Methanol propulsion engines often involve retrofitting existing diesel engines with modified fuel injection systems and corrosion-resistant materials to accommodate methanol's lower energy density and different combustion properties. Engine technology for LNG demands specialized dual-fuel or dedicated gas engines, while methanol propulsion benefits from adaptable modifications enabling use in conventional diesel engines with minimal structural changes.

Storage, Handling, and Safety Considerations

LNG propulsion requires cryogenic storage tanks maintained at -162degC to keep the fuel in liquid form, necessitating advanced insulation and boil-off gas management systems, whereas methanol propulsion utilizes ambient temperature storage in corrosion-resistant tanks, simplifying infrastructure. Handling LNG demands specialized equipment and strict safety protocols due to its extremely low temperature and flammability, while methanol poses toxicity and flammability risks but is less challenging to manage at standard conditions. Safety considerations for LNG focus on preventing leaks and rapid phase transition hazards, whereas methanol storage emphasizes spill containment and ventilation to mitigate toxic vapor exposure and fire hazards.

Regulatory Compliance and Future-Proofing

LNG propulsion systems comply with the IMO 2020 sulfur cap and stringent NOx emission standards, providing a clear regulatory advantage for current maritime environmental regulations. Methanol propulsion aligns with future IMO targets for carbon neutrality and offers compatibility with emerging green shipping initiatives due to its renewable production potential. Both fuels facilitate adherence to evolving emission control areas (ECAs), but methanol's role in circular economy strategies enhances vessel future-proofing amid tightening global decarbonization policies.

Economic Analysis: Costs and Investments

LNG propulsion systems generally require higher initial capital investment due to complex fuel storage and handling infrastructure, but offer lower fuel costs and reduced emissions compliance expenses over the vessel's lifecycle. Methanol propulsion presents lower upfront costs with simpler storage requirements but may incur higher operational expenses linked to methanol's relatively higher fuel price and limited supply infrastructure. Economic analysis indicates LNG is cost-effective for large-scale, long-distance shipping, while methanol suits smaller fleets seeking flexibility and lower initial expenditure.

Operational Experiences and Case Studies

LNG propulsion systems demonstrate superior fuel efficiency and lower emissions, as evidenced by extensive case studies such as the CMA CGM Jacques Saade, which achieved a 20% reduction in CO2 emissions compared to conventional fuels. Methanol propulsion has shown promising operational flexibility and safety advantages in vessels like Stena Germanica, with reduced SOx and NOx emissions and easier fuel handling due to methanol's liquid state at ambient conditions. Real-world data from LNG and methanol-powered fleets highlight LNG's established infrastructure and fuel availability, while methanol's emerging role emphasizes renewable sourcing and potential integration with existing shipping operations.

Future Trends in Marine Alternative Fuels

LNG propulsion is currently favored for its lower carbon emissions and established supply infrastructure, but methanol propulsion is gaining traction due to its potential for carbon-neutral production and easier storage. Future trends indicate a gradual shift towards methanol as shipping companies seek more sustainable fuels with reduced greenhouse gas footprints and compatibility with existing engine technologies. Innovations in methanol fuel cells and regulatory support from the International Maritime Organization are expected to accelerate its adoption in global marine fleets.

Dual-fuel engines

Dual-fuel engines using LNG propulsion offer higher energy density and lower greenhouse gas emissions compared to methanol propulsion, enhancing fuel flexibility and reducing operational costs in marine applications.

Bunkering infrastructure

LNG propulsion benefits from an expanding global bunkering infrastructure with numerous specialized terminals, while methanol bunkering remains limited but rapidly developing in key ports due to its ease of handling and lower infrastructure modification costs.

Cryogenic storage

LNG propulsion requires highly insulated cryogenic storage at approximately -162degC to maintain fuel in liquid form, whereas methanol propulsion uses less energy-intensive storage as methanol remains liquid at ambient temperatures, eliminating the need for cryogenic infrastructure.

Tank insulation systems

LNG propulsion requires advanced vacuum-insulated and multi-layered cryogenic tanks to maintain -162degC, whereas methanol propulsion utilizes simpler, less insulated tanks due to its ambient temperature storage.

Pilot fuel ratio

LNG propulsion typically achieves a lower pilot fuel ratio than methanol propulsion, enhancing combustion efficiency and reducing emissions in maritime engines.

Selective catalytic reduction (SCR)

Selective catalytic reduction (SCR) systems in LNG propulsion effectively reduce NOx emissions by converting nitrogen oxides into nitrogen and water, whereas methanol propulsion inherently produces lower NOx levels, often requiring less intensive SCR technology.

Boil-off gas management

LNG propulsion systems require advanced boil-off gas management technologies to capture and utilize evaporated methane, while methanol propulsion benefits from liquid stability at ambient temperatures, minimizing boil-off gas challenges and reducing fuel loss.

Fuel viscosity control

LNG propulsion benefits from low fuel viscosity requiring minimal control, while methanol propulsion demands precise viscosity management to ensure optimal fuel injection and combustion performance.

Methanol reforming

Methanol reforming in propulsion systems offers higher hydrogen density and lower emissions compared to LNG propulsion, making it a more efficient and environmentally friendly alternative for maritime fuel.

Greenhouse gas (GHG) emissions

Methanol propulsion reduces greenhouse gas (GHG) emissions by up to 15% compared to LNG propulsion, with lower methane slip and carbon dioxide output contributing to a cleaner maritime fuel alternative.

LNG propulsion vs Methanol propulsion Infographic

njnir.com

njnir.com