Double hull designs significantly enhance maritime safety by providing an additional layer of protection against leaks and hull breaches compared to single hull vessels. The double hull structure reduces the risk of oil spills and environmental damage during collisions or groundings, making it the preferred choice for modern tanker and cargo ship construction. Single hull ships, though cheaper to build, offer less resistance to damage and are increasingly phased out in favor of double hull counterparts to meet stricter international maritime regulations.

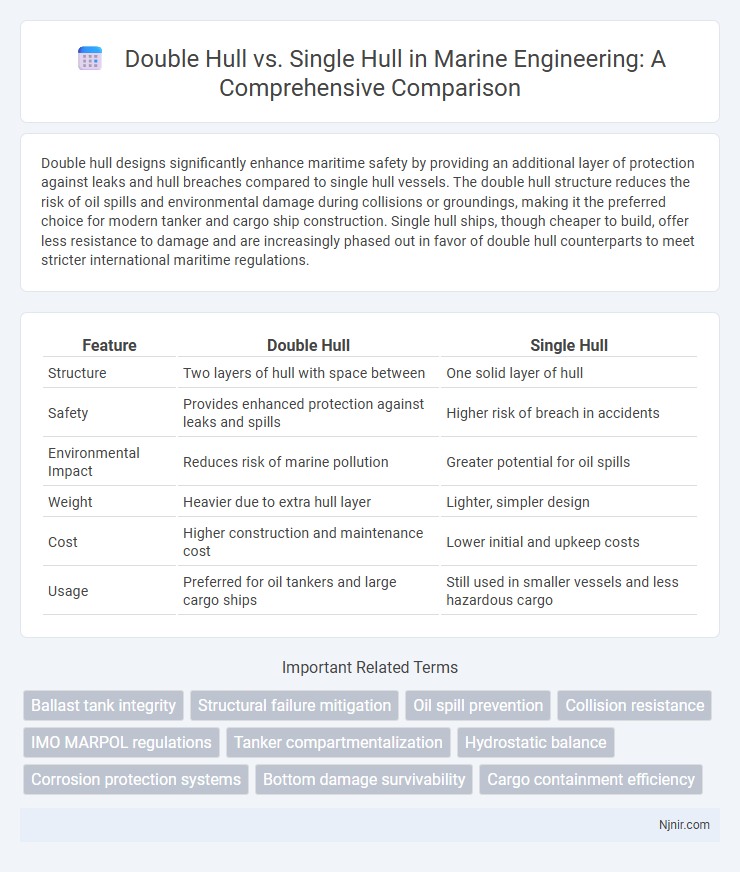

Table of Comparison

| Feature | Double Hull | Single Hull |

|---|---|---|

| Structure | Two layers of hull with space between | One solid layer of hull |

| Safety | Provides enhanced protection against leaks and spills | Higher risk of breach in accidents |

| Environmental Impact | Reduces risk of marine pollution | Greater potential for oil spills |

| Weight | Heavier due to extra hull layer | Lighter, simpler design |

| Cost | Higher construction and maintenance cost | Lower initial and upkeep costs |

| Usage | Preferred for oil tankers and large cargo ships | Still used in smaller vessels and less hazardous cargo |

Introduction to Marine Hull Designs

Double hulls and single hulls represent two fundamental marine hull designs, with double hulls featuring an additional outer layer that provides enhanced protection against leaks and environmental damage. Single hulls consist of a single layer of plating, offering simplicity and cost-effectiveness but less resistance to breaches in collision or grounding events. Modern maritime safety regulations prioritize double hulls for oil tankers to minimize spill risks and improve structural integrity.

Understanding Single Hull Structures

Single hull structures consist of a single layer of plating forming the outer shell of a vessel, providing basic containment and structural integrity. These designs lack the additional protective space found in double hulls, increasing vulnerability to breaches and environmental hazards during collisions or grounding. Single hull ships are still used in certain applications but are increasingly regulated or phased out due to higher risks of oil spills and environmental damage compared to double hull counterparts.

Overview of Double Hull Designs

Double hull designs feature two layers of watertight hull surfaces separated by a space, enhancing ship safety by reducing the risk of oil spills and structural damage during collisions or groundings. This design is prevalent in oil tankers and bulk carriers to comply with international maritime regulations such as MARPOL Annex I, which mandates double hulls for most oil tankers built after 1993. The double hull's outer layer absorbs impact energy while the inner hull maintains the vessel's integrity, offering improved environmental protection compared to single hull designs.

Historical Evolution of Hull Technology

The historical evolution of hull technology traces a transition from single hulls, predominantly used in early shipbuilding for their simpler construction and lower cost, to double hull designs driven by enhanced safety and environmental regulations. Double hulls became prominent after significant oil spill disasters in the late 20th century, leading to regulatory mandates such as the Oil Pollution Act of 1990, which required tankers to incorporate double hulls to reduce spill risks. This shift reflects the maritime industry's increasing emphasis on structural integrity and environmental protection through advanced hull engineering.

Safety Implications: Double Hull vs Single Hull

Double hull designs significantly enhance maritime safety by providing an additional barrier that reduces the risk of oil spills and environmental contamination in the event of a hull breach. Single hull vessels lack this protective layer, making them more vulnerable to structural damage and consequent hazardous leaks during collisions or groundings. Regulatory frameworks such as MARPOL mandate double hulls for oil tankers to minimize pollution incidents, underscoring their critical role in improving operational safety standards.

Environmental Impact and Spill Prevention

Double hull designs significantly reduce the risk of oil spills by providing an additional barrier between cargo and the environment, minimizing leakage during collisions or groundings. Single hull vessels lack this protective layer, increasing the likelihood of environmental contamination in accidents. Regulatory frameworks, such as the MARPOL Convention, mandate double hulls for oil tankers to enhance spill prevention and protect marine ecosystems.

Structural Strength and Durability Comparison

Double hull designs provide enhanced structural strength by incorporating two layers of watertight hull surfaces, which significantly improve resistance to breaches and impacts compared to single hulls. The additional space between the outer and inner hulls acts as a protective barrier, reducing the risk of structural failure and corrosion, thereby extending the vessel's durability under harsh marine conditions. Single hull vessels, while lighter and less costly, are more susceptible to damage from collisions or grounding, making them less reliable in maintaining structural integrity over extended service periods.

Cost Analysis: Construction and Maintenance

Double hull vessels require higher initial construction costs due to the extra layer of steel and complex design, significantly increasing material and labor expenses compared to single hull ships. Maintenance costs are also elevated for double hulls, as inspections, repairs, and corrosion protection demand more resources to preserve the integrity of both hull layers. However, the investment often results in long-term savings by reducing environmental risks and potential regulatory fines associated with oil spills or hull breaches.

Regulatory Standards and Compliance

Double hull designs are mandated by international regulatory standards such as the International Maritime Organization's MARPOL Annex I to minimize oil spill risks and enhance environmental protection, especially for oil tankers operating in sensitive waters. Single hull vessels, while historically common, face stricter operational restrictions and are subject to phasing out under conventions like the Oil Pollution Act of 1990 in the United States. Compliance with these regulations requires double hulls to provide an added barrier against breaches, reflecting their superior safety and environmental performance compared to single hulls.

Future Trends in Marine Hull Innovation

Future trends in marine hull innovation emphasize the shift towards double hull designs due to their enhanced environmental protection and structural integrity, reducing the risk of oil spills and improving safety standards. Advanced materials like composite polymers and lightweight alloys are being integrated to increase fuel efficiency and durability while meeting stricter regulatory requirements. Research in smart hull technologies incorporating sensors and self-healing coatings promises to revolutionize maintenance and real-time damage detection in both single and double hull vessels.

Ballast tank integrity

Double hull designs enhance ballast tank integrity by providing an additional protective layer that reduces the risk of leaks and structural damage compared to single hull vessels.

Structural failure mitigation

Double hulls significantly reduce structural failure risks by providing an additional protective barrier that absorbs impacts and prevents hull breaches compared to single hulls.

Oil spill prevention

Double hull designs reduce oil spill risks by providing an extra barrier between the cargo and the seawater, significantly minimizing the likelihood of spills in collisions or groundings compared to single hull vessels.

Collision resistance

Double hulls provide significantly enhanced collision resistance compared to single hulls by incorporating an additional outer layer that absorbs impact and reduces breach risk.

IMO MARPOL regulations

IMO MARPOL regulations mandate double hull designs for oil tankers to reduce pollution risks, favoring double hulls over single hulls for enhanced environmental protection.

Tanker compartmentalization

Double hull tankers feature an additional outer hull layer creating separate ballast tanks that enhance compartmentalization and reduce spill risk compared to single hull tankers with a single structural barrier around cargo tanks.

Hydrostatic balance

Double hull vessels enhance hydrostatic balance by providing increased structural integrity and improved buoyancy distribution compared to single hull designs.

Corrosion protection systems

Double hull ships provide enhanced corrosion protection by creating a barrier between the cargo and the sea, significantly reducing the risk of leaks and structural damage compared to single hull designs that expose the hull directly to corrosive marine environments.

Bottom damage survivability

Double hulls provide superior bottom damage survivability by offering an extra protective layer that reduces the risk of flooding and structural failure compared to single hulls.

Cargo containment efficiency

Double hull designs significantly enhance cargo containment efficiency by providing an additional protective barrier that reduces the risk of spillage and structural damage compared to single hull vessels.

Double hull vs Single hull Infographic

njnir.com

njnir.com