CPP (Controllable Pitch Propeller) shafts offer enhanced maneuverability and fuel efficiency by allowing variable blade angles without changing shaft speed, unlike FPP (Fixed Pitch Propeller) shafts which have a constant blade angle requiring speed adjustments for thrust control. CPP shafts provide smoother operation and reduced wear on engine components due to their ability to maintain optimal engine loading, whereas FPP shafts can cause more vibration and stress under varying load conditions. Maintenance of CPP systems tends to be more complex and costly compared to FPP shafts, but the operational flexibility and efficiency gains often justify the investment in marine engineering applications.

Table of Comparison

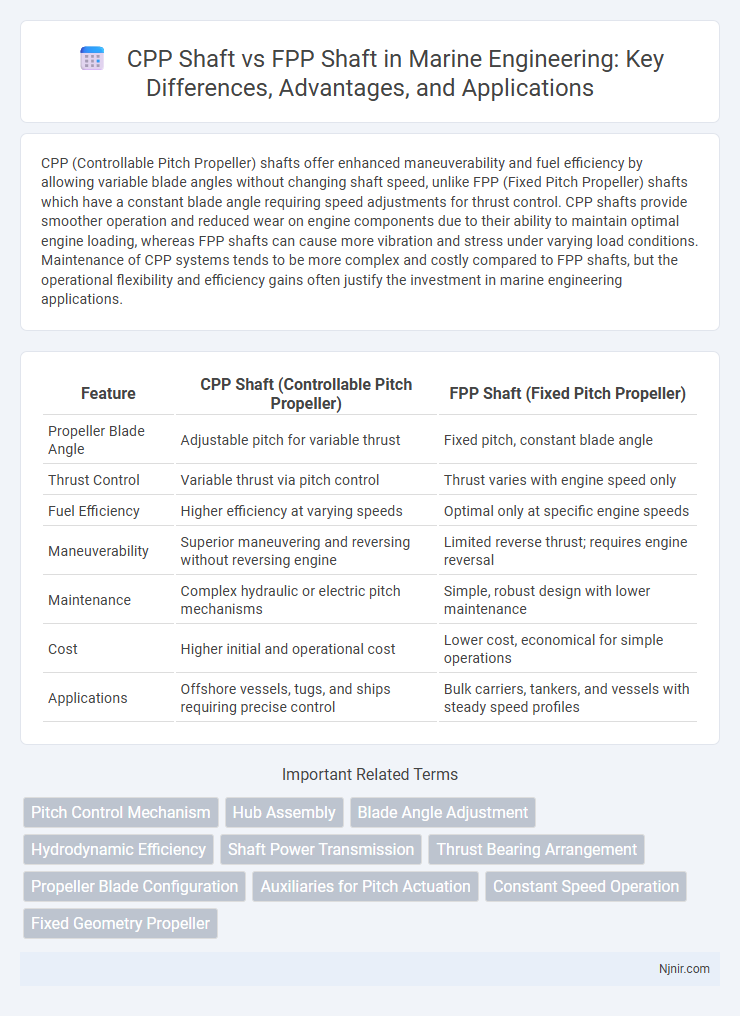

| Feature | CPP Shaft (Controllable Pitch Propeller) | FPP Shaft (Fixed Pitch Propeller) |

|---|---|---|

| Propeller Blade Angle | Adjustable pitch for variable thrust | Fixed pitch, constant blade angle |

| Thrust Control | Variable thrust via pitch control | Thrust varies with engine speed only |

| Fuel Efficiency | Higher efficiency at varying speeds | Optimal only at specific engine speeds |

| Maneuverability | Superior maneuvering and reversing without reversing engine | Limited reverse thrust; requires engine reversal |

| Maintenance | Complex hydraulic or electric pitch mechanisms | Simple, robust design with lower maintenance |

| Cost | Higher initial and operational cost | Lower cost, economical for simple operations |

| Applications | Offshore vessels, tugs, and ships requiring precise control | Bulk carriers, tankers, and vessels with steady speed profiles |

Introduction to CPP and FPP Shafts in Marine Engineering

CPP (Controllable Pitch Propeller) shafts enable variable blade angles, optimizing thrust and fuel efficiency for diverse marine conditions, while FPP (Fixed Pitch Propeller) shafts have fixed blade angles, providing simplicity and reliability. CPP shafts require more complex mechanical systems like hydraulic controls for pitch adjustment, enhancing maneuverability and speed control, crucial for vessels operating in variable load scenarios. FPP shafts are often preferred for applications demanding straightforward maintenance and consistent performance, such as in tankers and bulk carriers.

Fundamental Differences Between CPP and FPP Shafts

CPP (Controllable Pitch Propeller) shafts feature a variable pitch mechanism that allows blade angle adjustment during operation, enhancing fuel efficiency and maneuverability. FPP (Fixed Pitch Propeller) shafts have blades fixed at a set angle, offering simpler design and lower initial cost but limited operational flexibility. The fundamental difference lies in CPP's ability to optimize thrust dynamically, whereas FPP relies on constant blade geometry for propulsion.

Design Characteristics of CPP Shafts

CPP shafts feature a hollow, cylindrical design that allows for greater flexibility and weight reduction compared to FPP shafts. Their construction incorporates complex pitch and blade angle adjustments directly along the shaft, enabling real-time propulsion efficiency optimization. The use of high-strength, corrosion-resistant alloys enhances durability while maintaining the shaft's lightweight properties in CPP systems.

Design Overview of FPP Shafts

FPP (Fixed Pitch Propeller) shafts feature a robust design optimized for steady rotational speed and constant thrust generation, ensuring reliable propulsion in marine applications. These shafts are engineered with precision-machined surfaces and reinforced materials to withstand high torque and vibrations, enhancing durability and operational efficiency. The fixed pitch design simplifies maintenance and reduces mechanical complexity compared to CPP (Controllable Pitch Propeller) shafts, contributing to lower lifecycle costs.

Operational Efficiency: CPP vs FPP Shafts

Controllable Pitch Propeller (CPP) shafts offer superior operational efficiency compared to Fixed Pitch Propeller (FPP) shafts by allowing adjustable blade angles that optimize thrust across varying speeds and load conditions. This flexibility reduces fuel consumption and enhances maneuverability, particularly in variable sea states or during complex maneuvers. Conversely, FPP shafts maintain constant blade angles, which limits performance adaptability and often results in less efficient fuel usage during off-design operating conditions.

Fuel Consumption and Performance Comparison

CPP shafts offer superior fuel efficiency by allowing variable pitch adjustment, optimizing propeller performance across different operating conditions and reducing fuel consumption. FPP shafts have fixed blade angles, resulting in less flexibility and generally higher fuel consumption during varying speeds and loads. Performance-wise, CPP shafts provide better maneuverability and power control, leading to enhanced overall efficiency compared to FPP shafts.

Maintenance Requirements and Lifecycle Costs

CPP (Controllable Pitch Propeller) shafts require more frequent inspection and maintenance due to their complex pitch adjustment mechanisms, increasing labor costs and downtime. FPP (Fixed Pitch Propeller) shafts have simpler designs, leading to lower maintenance requirements and longer intervals between inspections, reducing overall lifecycle expenses. The total lifecycle cost of CPP shafts is generally higher because of these additional maintenance demands and the cost of specialized parts.

Suitability for Various Vessel Types

CPP shafts provide superior maneuverability and are ideal for vessels requiring frequent speed adjustments, such as ferries and tugboats, due to their reverse pitch capability. FPP shafts are better suited for vessels with consistent cruising speeds, including cargo ships and bulk carriers, because of their simple and robust design. Selecting the appropriate shaft type depends on vessel operational profiles and performance requirements, directly impacting fuel efficiency and handling characteristics.

Environmental Impact Considerations

CPP (Controllable Pitch Propeller) shafts typically offer better fuel efficiency compared to FPP (Fixed Pitch Propeller) shafts, leading to reduced greenhouse gas emissions over a vessel's operational life. The ability to optimize blade pitch in CPP systems allows for improved engine performance and lower fuel consumption, minimizing environmental pollution. However, CPP shafts may require more complex maintenance and materials, which can influence the overall environmental footprint during manufacturing and servicing stages.

Future Trends and Technological Innovations in Propulsion Shafts

The future trends in CPP (Controllable Pitch Propeller) and FPP (Fixed Pitch Propeller) shafts emphasize enhanced materials such as carbon fiber composites for reduced weight and increased durability. Technological innovations include integrated shaft monitoring systems with IoT sensors enabling real-time performance analysis and predictive maintenance, improving efficiency and reducing downtime. Advances in hydrodynamic design and smart shaft alignment technologies aim to optimize propulsion efficiency and minimize vibration, contributing to sustainable maritime operations.

Pitch Control Mechanism

CPP shafts use adjustable pitch blades controlled hydraulically for precise thrust variation, whereas FPP shafts have fixed blades requiring engine speed changes to alter thrust.

Hub Assembly

CPP shaft hub assemblies provide enhanced durability and easier maintenance compared to FPP shaft hub assemblies, optimizing propulsion system performance and reliability.

Blade Angle Adjustment

CPP shafts enable precise blade angle adjustment for improved propulsion efficiency, while FPP shafts have fixed blades with no angle adjustment capability.

Hydrodynamic Efficiency

CPP shafts provide superior hydrodynamic efficiency by enabling precise variable pitch adjustments that optimize propeller performance across diverse operating conditions compared to fixed-pitch FPP shafts.

Shaft Power Transmission

CPP shafts provide variable pitch propeller control enhancing shaft power transmission efficiency, while FPP shafts offer fixed blade angles resulting in simpler but less flexible power delivery.

Thrust Bearing Arrangement

CPP shafts feature thrust bearing arrangements integrated within the hub for direct load transfer, while FPP shafts utilize separate thrust blocks positioned aft of the stern tube to manage axial forces efficiently.

Propeller Blade Configuration

CPP shafts feature adjustable pitch propeller blades allowing variable thrust control, whereas FPP shafts use fixed pitch blades optimized for consistent propulsion efficiency.

Auxiliaries for Pitch Actuation

CPP shafts utilize integral hydraulic auxiliary systems for precise pitch actuation, whereas FPP shafts rely on external mechanical linkages for blade pitch adjustment.

Constant Speed Operation

CPP shafts maintain optimal propulsion efficiency by adjusting blade pitch for constant speed operation, while FPP shafts rely on fixed blade angles requiring variable engine speeds to manage vessel velocity.

Fixed Geometry Propeller

Fixed Geometry Propeller (FGP) shafts offer greater durability and simpler maintenance compared to Controllable Pitch Propeller (CPP) shafts, providing optimized efficiency for vessels operating at consistent speeds.

CPP shaft vs FPP shaft Infographic

njnir.com

njnir.com