Air-start systems in marine engineering utilize compressed air to initiate engine rotation, offering reliable performance in harsh environments and reducing electrical load on the ship's power systems. Electric-start systems rely on battery-powered motors to crank the engine, providing faster and quieter startups but requiring robust electrical infrastructure and maintenance. Choosing between air-start and electric-start systems depends on vessel size, operational conditions, and maintenance preferences, with air-start favored for large diesel engines and electric-start suited for smaller or less demanding applications.

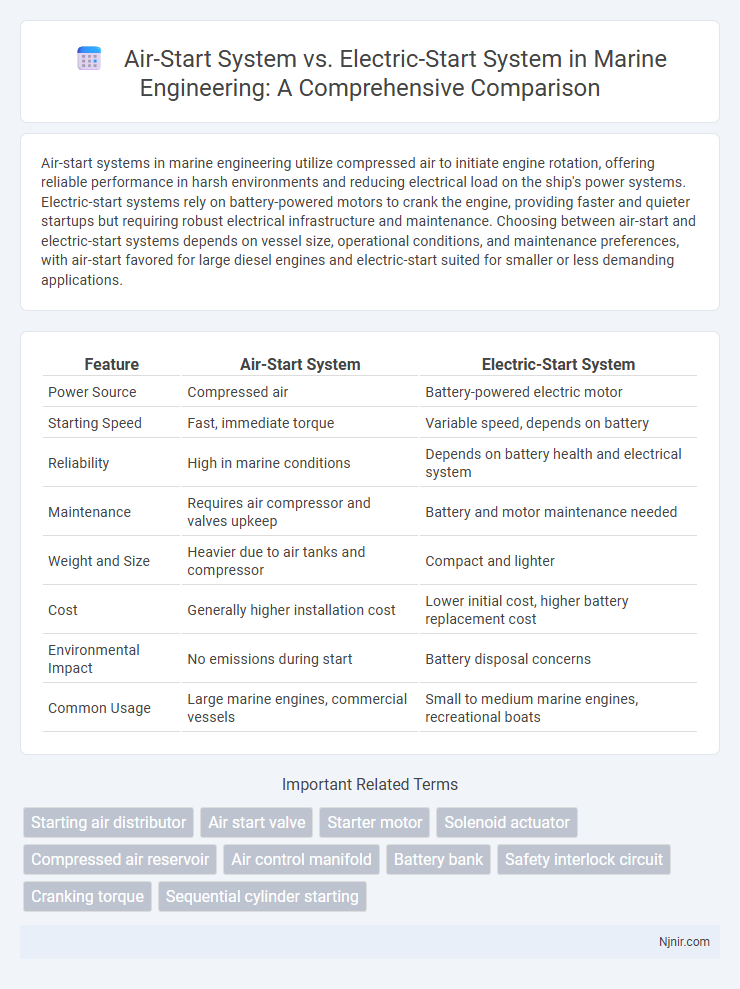

Table of Comparison

| Feature | Air-Start System | Electric-Start System |

|---|---|---|

| Power Source | Compressed air | Battery-powered electric motor |

| Starting Speed | Fast, immediate torque | Variable speed, depends on battery |

| Reliability | High in marine conditions | Depends on battery health and electrical system |

| Maintenance | Requires air compressor and valves upkeep | Battery and motor maintenance needed |

| Weight and Size | Heavier due to air tanks and compressor | Compact and lighter |

| Cost | Generally higher installation cost | Lower initial cost, higher battery replacement cost |

| Environmental Impact | No emissions during start | Battery disposal concerns |

| Common Usage | Large marine engines, commercial vessels | Small to medium marine engines, recreational boats |

Overview of Marine Engine Starting Systems

Marine engine starting systems primarily consist of air-start and electric-start mechanisms, each designed to initiate engine operation efficiently. Air-start systems use compressed air to turn the engine's crankshaft, ideal for large marine engines due to their reliability and minimal electrical demand. Electric-start systems rely on high-capacity batteries and electric motors, commonly used in smaller vessels for quick and convenient engine ignition.

Fundamental Principles: Air-Start vs Electric-Start

Air-start systems rely on compressed air to spin the engine's turbine and initiate combustion, making them particularly effective in large industrial engines and aircraft. Electric-start systems utilize electric motors powered by batteries to crank the engine until it starts, common in automobiles and smaller machinery due to their simplicity and quick response. Both systems convert stored energy--air pressure in air-start and electrical energy in electric-start--into mechanical motion to initiate engine operation.

Key Components of Air-Start Systems

Key components of air-start systems include an air receiver tank, air starter motor, control valves, and high-pressure air supply lines. The air receiver tank stores compressed air necessary to initiate engine startup, while the air starter motor converts this compressed air into mechanical energy to crank the engine. Control valves regulate the flow and pressure of air from the receiver tank to the motor, ensuring efficient and reliable engine start-up.

Key Components of Electric-Start Systems

Electric-start systems primarily consist of a powerful starter motor, a rechargeable battery, an ignition switch, and a solenoid or relay to control the electrical current. The starter motor engages the engine's flywheel to initiate combustion, while the battery provides the necessary electrical energy to power the system. Key components also include wiring harnesses and safety features such as circuit breakers or fuses to protect against electrical faults.

Operational Efficiency Comparison

Air-start systems utilize compressed air to initiate engine operation, offering high reliability in heavy-duty applications but incurring longer start times and increased maintenance due to air compressor wear. Electric-start systems provide rapid and consistent engine starts with lower maintenance demands, enhancing operational efficiency in smaller engines and vehicles but may struggle with power limitations under extreme conditions. Evaluating engine size, duty cycle, and environmental factors is crucial in optimizing operational efficiency when choosing between air-start and electric-start systems.

Safety Considerations in Starting Systems

Air-start systems reduce risk of electrical sparks and fires by using compressed air to initiate engine operation, making them ideal for hazardous environments such as oil refineries and chemical plants. Electric-start systems require robust insulation and circuit protection to prevent short circuits and ensure operator safety during engine activation. Proper maintenance and timely inspection of both systems are essential to mitigate risks associated with mechanical failure or electrical faults, enhancing overall operational safety.

Maintenance Requirements and Downtime

Air-start systems demand regular inspection of air compressors, valves, and pneumatic lines to prevent leaks and ensure consistent pressure, leading to potential downtime during maintenance cycles. Electric-start systems require less frequent attention but involve critical checks of battery health, wiring, and starter motor components to avoid unexpected failures. Overall, electric-start systems generally present lower maintenance demands and reduced downtime compared to the more complex and maintenance-intensive air-start systems.

Cost Analysis: Installation and Operation

Air-start systems typically incur higher initial installation costs due to the need for complex pneumatic components and integration with existing engines, while electric-start systems feature lower upfront expenses as they rely on simpler electrical circuits and batteries. Operational costs for air-start systems tend to be elevated because of maintenance requirements for compressors, airlines, and valves, compared to electric-start systems, which benefit from reduced maintenance and energy efficiency linked to battery technology. Life cycle cost analysis reveals electric-start systems as more cost-effective in applications prioritizing low operational downtime and energy consumption.

Suitability for Different Vessel Types

Air-start systems excel in large marine engines, such as those on cargo ships and tankers, where high torque and reliability under heavy loads are critical. Electric-start systems are better suited for smaller vessels like fishing boats, yachts, and recreational crafts, offering easier installation, lower maintenance, and quicker engine starts. Vessel operators choose between these systems based on engine size, power requirements, and operational environment to ensure optimal performance and efficiency.

Future Trends in Marine Engine Starting Technologies

Future trends in marine engine starting technologies emphasize increased adoption of electric-start systems due to their efficiency, lower maintenance, and integration with advanced battery technologies such as lithium-ion and solid-state batteries. Air-start systems, while robust and reliable for large marine engines, face challenges with weight and complexity, prompting innovation in hybrid electric-air start solutions to optimize performance and reduce emissions. The shift towards greener marine operations drives research in smart start systems featuring IoT connectivity and predictive maintenance capabilities, enhancing operational reliability and fuel efficiency in maritime vessels.

Starting air distributor

The air-start system's starting air distributor precisely times high-pressure air delivery to engine cylinders, enhancing startup reliability compared to the electric-start system's reliance on electrical motors for initial engine rotation.

Air start valve

The air start valve in an air-start system controls the flow of compressed air to initiate engine startup, providing faster engagement and higher torque compared to the slower, lower-torque electric-start system.

Starter motor

The air-start system uses compressed air to drive a pneumatic starter motor, while the electric-start system relies on an electric starter motor powered by the vehicle's battery for engine ignition.

Solenoid actuator

The solenoid actuator in air-start systems provides rapid, high-torque engagement for engine startup, while in electric-start systems, it efficiently manages electrical current to activate the starter motor for reliable ignition.

Compressed air reservoir

The air-start system relies on a high-pressure compressed air reservoir to rapidly spin the engine for ignition, while the electric-start system depends on a battery-powered electric motor without requiring stored compressed air.

Air control manifold

The air control manifold in an air-start system regulates compressed air flow to initiate engine rotation, providing a reliable and lightweight alternative to the electric-start system's reliance on electrical power and battery capacity.

Battery bank

Electric-start systems rely heavily on a high-capacity battery bank to provide consistent power for engine ignition, whereas air-start systems use compressed air sources, minimizing dependence on battery banks.

Safety interlock circuit

The Air-start system and Electric-start system differ fundamentally in their safety interlock circuits, with the Air-start system utilizing pneumatic pressure-sensitive interlocks to prevent accidental engine engagement, while the Electric-start system employs electrical interlock circuits integrated with ignition and starter relay controls to ensure engine activation only under safe operational conditions.

Cranking torque

Air-start systems provide higher cranking torque compared to electric-start systems, making them more effective for large engines requiring rapid and powerful startup.

Sequential cylinder starting

The air-start system enables rapid sequential cylinder starting by directing compressed air to each cylinder individually, improving engine start-up efficiency compared to the electric-start system that relies on a single electric motor to crank all cylinders simultaneously.

Air-start system vs Electric-start system Infographic

njnir.com

njnir.com