LNG fuel offers significant environmental advantages over marine diesel oil, including lower emissions of sulfur oxides, nitrogen oxides, and carbon dioxide, contributing to cleaner and more sustainable maritime operations. Its higher energy density and improved combustion efficiency result in enhanced engine performance and reduced fuel consumption. However, the adoption of LNG requires specialized storage and handling infrastructure, influencing initial investment and operational logistics in marine engineering.

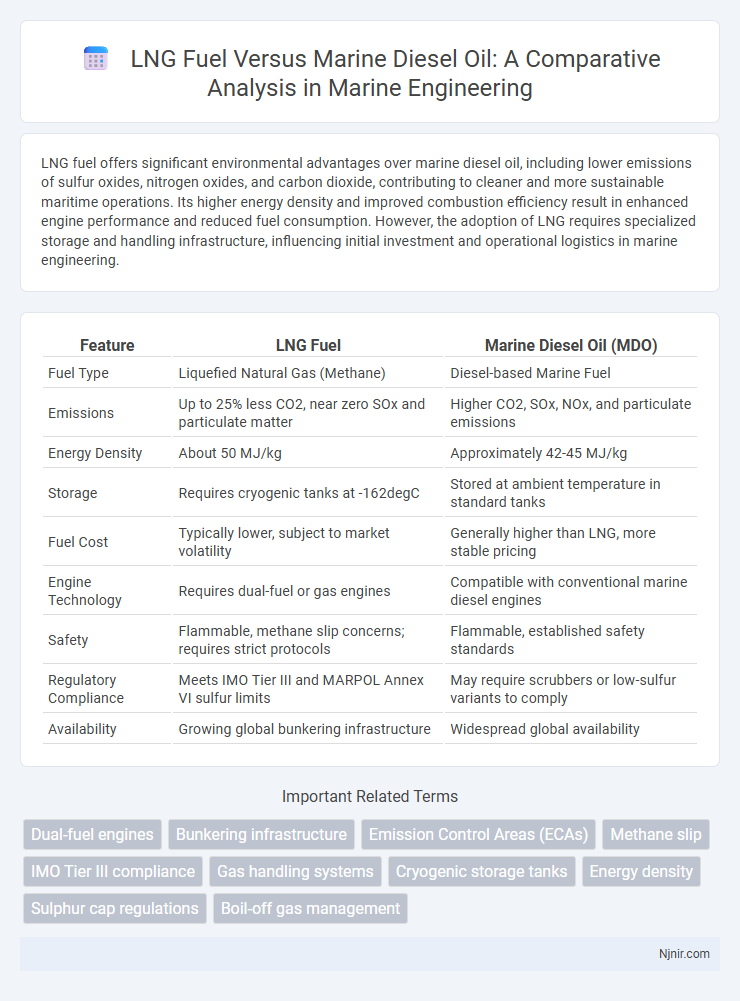

Table of Comparison

| Feature | LNG Fuel | Marine Diesel Oil (MDO) |

|---|---|---|

| Fuel Type | Liquefied Natural Gas (Methane) | Diesel-based Marine Fuel |

| Emissions | Up to 25% less CO2, near zero SOx and particulate matter | Higher CO2, SOx, NOx, and particulate emissions |

| Energy Density | About 50 MJ/kg | Approximately 42-45 MJ/kg |

| Storage | Requires cryogenic tanks at -162degC | Stored at ambient temperature in standard tanks |

| Fuel Cost | Typically lower, subject to market volatility | Generally higher than LNG, more stable pricing |

| Engine Technology | Requires dual-fuel or gas engines | Compatible with conventional marine diesel engines |

| Safety | Flammable, methane slip concerns; requires strict protocols | Flammable, established safety standards |

| Regulatory Compliance | Meets IMO Tier III and MARPOL Annex VI sulfur limits | May require scrubbers or low-sulfur variants to comply |

| Availability | Growing global bunkering infrastructure | Widespread global availability |

Introduction to LNG Fuel and Marine Diesel Oil

Liquefied Natural Gas (LNG) fuel is a cryogenically cooled natural gas used in marine engines, offering lower emissions and higher energy efficiency compared to traditional Marine Diesel Oil (MDO). Marine Diesel Oil is a heavy fuel variant primarily composed of residual oils, widely used for its high energy content and established refueling infrastructure in shipping. LNG fuel reduces sulfur oxide (SOx), nitrogen oxide (NOx), and particulate matter emissions, aligning with International Maritime Organization (IMO) environmental regulations, whereas MDO remains prevalent due to its availability and engine compatibility.

Environmental Impact Comparison: LNG vs Marine Diesel

LNG fuel significantly reduces greenhouse gas emissions compared to marine diesel oil, cutting CO2 emissions by up to 25% and virtually eliminating sulfur oxide (SOx) emissions. LNG also lowers nitrogen oxide (NOx) emissions by up to 85%, contributing to improved air quality and compliance with IMO Tier III regulations. Marine diesel oil combustion produces higher particulate matter and sulfur content, leading to greater environmental pollution and health risks.

Energy Efficiency and Performance Analysis

LNG fuel offers higher energy efficiency compared to marine diesel oil (MDO) due to its superior combustion properties and lower carbon content, resulting in reduced fuel consumption and emissions. Performance analysis shows LNG-powered vessels achieve enhanced engine thermal efficiency and smoother operation, contributing to cost savings and compliance with stringent IMO emission regulations. While MDO remains widely used for its availability and energy density, LNG's benefits in fuel economy and environmental impact position it as a strategic alternative for sustainable maritime propulsion.

Fuel Storage and Handling Requirements

LNG fuel requires cryogenic storage tanks maintained at extremely low temperatures around -162degC to keep the gas in liquid form, demanding specialized insulation and handling systems to prevent boil-off and ensure safety. Marine Diesel Oil (MDO) can be stored at ambient temperatures in conventional fuel tanks, making storage and handling less complex and more compatible with existing infrastructure. LNG's handling involves advanced safety protocols due to its flammability and low temperature, whereas MDO handling is less hazardous but requires strict measures to prevent spills and contamination.

Cost Implications: Initial Investment and Operating Expenses

LNG fuel requires a higher initial investment due to the need for specialized cryogenic storage tanks and engine modifications, whereas marine diesel oil systems benefit from established infrastructure and lower upfront costs. Operating expenses for LNG are generally lower, driven by reduced fuel prices and improved engine efficiency that leads to less maintenance and emissions compliance costs. Over the vessel's lifecycle, the total cost of ownership for LNG-fueled ships can be more economical despite the higher capital expenditure, especially under stringent environmental regulations and fuel price volatility.

Regulatory Compliance and Emissions Standards

LNG fuel significantly reduces sulfur oxides (SOx) emissions, enabling easier compliance with IMO 2020 sulfur cap regulations compared to marine diesel oil (MDO). Stricter Environmental Protection Agency (EPA) Tier 4 standards favor LNG due to its lower nitrogen oxides (NOx) and particulate matter emissions, supporting cleaner air initiatives in emission control areas (ECAs). Operators choosing LNG achieve greater alignment with upcoming International Maritime Organization (IMO) greenhouse gas reduction targets, positioning LNG as a strategic solution for future-proof regulatory compliance.

Engine Technology and Adaptation

LNG fuel engines utilize high-pressure direct injection systems and dual-fuel technology to optimize combustion efficiency and reduce emissions, contrasting with marine diesel oil engines that rely on traditional compression ignition with higher sulfur content. Adaptation of LNG engines requires modifications such as cryogenic fuel storage and enhanced safety systems to manage liquefied gas properties. Marine vessels retrofitted from diesel to LNG face challenges in engine calibration and fuel delivery systems to ensure compliance with International Maritime Organization (IMO) emission regulations.

Infrastructure Availability and Bunkering

LNG fuel requires specialized infrastructure, including cryogenic storage tanks and dedicated bunkering facilities, which are currently limited but expanding in major ports worldwide. Marine Diesel Oil (MDO) benefits from a well-established global supply chain with widespread bunkering availability, ensuring flexibility and convenience for marine operators. The growth of LNG bunkering networks, supported by increasing environmental regulations, is enhancing LNG's competitiveness compared to MDO in terms of refueling infrastructure.

Safety Considerations in Fuel Usage

LNG fuel significantly reduces fire and explosion risks due to its non-toxic, non-corrosive, and low-flammability properties compared to Marine Diesel Oil (MDO), which is more combustible and produces higher soot and sulfur emissions. LNG tanks require robust cryogenic insulation and leak detection systems, while MDO systems must prioritize spill prevention and vapor control to mitigate environmental hazards. Crew training on handling LNG's cryogenic nature and emergency procedures is critical, whereas MDO safety efforts focus on managing fuel flammability and contamination risks.

Future Trends in Marine Fuel Choices

LNG fuel is increasingly favored in the marine industry for its lower sulfur emissions and compliance with IMO 2020 regulations, signaling a shift towards cleaner propulsion technologies. Marine diesel oil, while still prevalent, faces growing restrictions due to higher greenhouse gas emissions and particulate matter, prompting vessels to explore alternative fuels. Future trends indicate a rising adoption of LNG and other zero-emission fuels like hydrogen and ammonia, driven by stringent environmental policies and advancements in fuel infrastructure.

Dual-fuel engines

Dual-fuel engines optimizing LNG fuel reduce greenhouse gas emissions by up to 20% and lower sulfur and particulate matter compared to marine diesel oil in maritime applications.

Bunkering infrastructure

LNG fuel requires specialized cryogenic bunkering infrastructure due to its low temperature and high pressure storage needs, whereas marine diesel oil benefits from widespread existing bunkering facilities with simpler handling requirements.

Emission Control Areas (ECAs)

LNG fuel significantly reduces sulfur oxide (SOx) and nitrogen oxide (NOx) emissions compared to marine diesel oil, making it a preferred choice for compliance with stringent Emission Control Areas (ECAs) regulations.

Methane slip

Methane slip from LNG fuel combustion significantly impacts greenhouse gas emissions compared to marine diesel oil despite LNG's lower CO2 output.

IMO Tier III compliance

LNG fuel enables ships to achieve IMO Tier III emissions compliance by significantly reducing nitrogen oxides (NOx) compared to Marine Diesel Oil.

Gas handling systems

LNG fuel systems utilize cryogenic gas handling technology for safe storage and vaporization, while marine diesel oil systems rely on conventional liquid fuel handling and combustion processes.

Cryogenic storage tanks

Cryogenic storage tanks for LNG fuel provide superior energy density and lower emissions compared to traditional marine diesel oil tanks, enabling more efficient and environmentally friendly marine propulsion.

Energy density

Liquefied Natural Gas (LNG) has an energy density of approximately 21.1 MJ/L, significantly lower than Marine Diesel Oil's energy density of around 35.8 MJ/L, impacting fuel storage and range in maritime applications.

Sulphur cap regulations

LNG fuel complies with the International Maritime Organization's 0.5% sulphur cap regulation by producing near-zero sulphur emissions, while marine diesel oil requires expensive sulphur scrubbers or low-sulphur blends to meet the same standards.

Boil-off gas management

Effective boil-off gas management in LNG fuel systems minimizes emissions and improves fuel efficiency compared to marine diesel oil, which lacks comparable vapor handling technologies.

LNG Fuel vs Marine Diesel Oil Infographic

njnir.com

njnir.com