Diesel-electric propulsion offers high fuel efficiency and reduced emissions by combining diesel engines with electric generators to power electric motors, making it ideal for vessels requiring flexible speed control and lower noise levels. Dual-fuel propulsion systems enhance operational versatility by allowing ships to switch between traditional diesel fuel and cleaner alternatives like LNG, significantly decreasing sulfur oxide and nitrogen oxide emissions while maintaining engine performance. Choosing between these systems depends on factors such as fuel availability, environmental regulations, and vessel operational profiles.

Table of Comparison

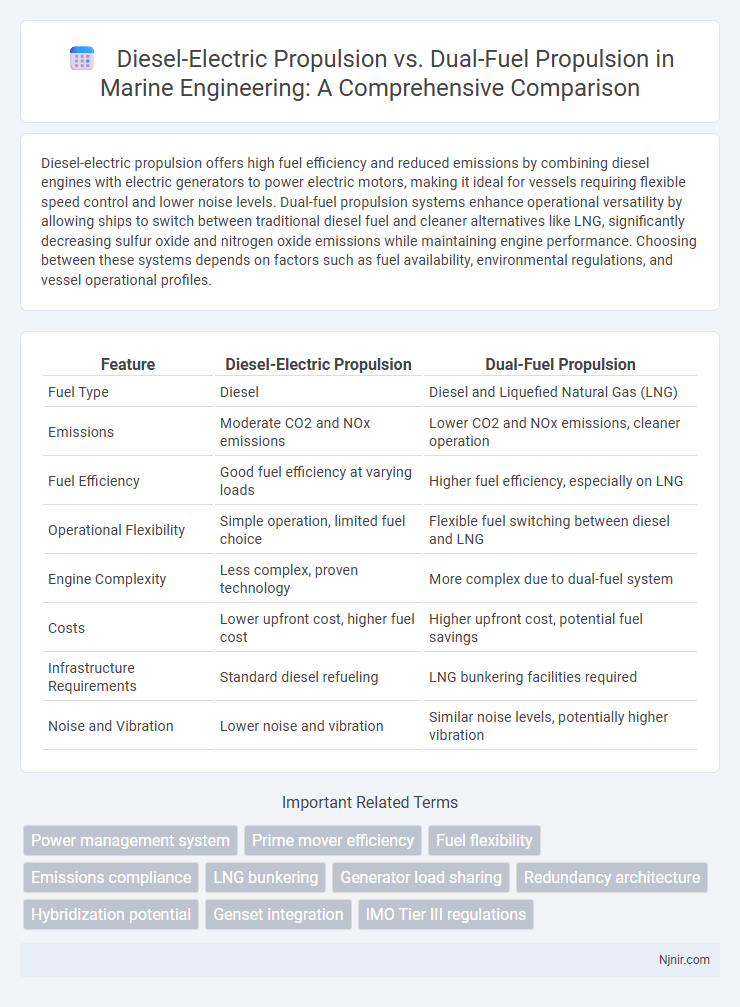

| Feature | Diesel-Electric Propulsion | Dual-Fuel Propulsion |

|---|---|---|

| Fuel Type | Diesel | Diesel and Liquefied Natural Gas (LNG) |

| Emissions | Moderate CO2 and NOx emissions | Lower CO2 and NOx emissions, cleaner operation |

| Fuel Efficiency | Good fuel efficiency at varying loads | Higher fuel efficiency, especially on LNG |

| Operational Flexibility | Simple operation, limited fuel choice | Flexible fuel switching between diesel and LNG |

| Engine Complexity | Less complex, proven technology | More complex due to dual-fuel system |

| Costs | Lower upfront cost, higher fuel cost | Higher upfront cost, potential fuel savings |

| Infrastructure Requirements | Standard diesel refueling | LNG bunkering facilities required |

| Noise and Vibration | Lower noise and vibration | Similar noise levels, potentially higher vibration |

Introduction to Marine Propulsion Systems

Diesel-electric propulsion systems in marine vessels use diesel engines to generate electricity, which then powers electric motors connected to the propellers, offering high efficiency and flexible power management. Dual-fuel propulsion systems combine conventional diesel engines with the ability to operate on alternative fuels like LNG, reducing emissions and enhancing fuel versatility. Both systems represent advanced marine propulsion technologies aimed at improving operational efficiency and environmental sustainability in modern shipping.

Overview of Diesel-Electric Propulsion

Diesel-electric propulsion systems utilize diesel engines to generate electricity, which then powers electric motors connected to the ship's propellers, offering enhanced fuel efficiency and operational flexibility. This technology enables variable speed control and reduces mechanical complexity compared to conventional diesel drives, resulting in lower maintenance costs and improved reliability. Widely implemented in naval vessels, cruise ships, and icebreakers, diesel-electric propulsion supports diverse power demands and environmental regulations through optimized energy management.

Fundamentals of Dual-Fuel Propulsion

Dual-fuel propulsion systems operate by combusting both conventional marine diesel oil and liquefied natural gas (LNG) in a single engine, optimizing fuel efficiency and reducing emissions compared to traditional diesel-electric propulsion. By utilizing LNG as a primary fuel, dual-fuel engines achieve lower sulfur oxide (SOx), nitrogen oxide (NOx), and particulate matter emissions, aligning with stringent International Maritime Organization (IMO) regulations. The fundamental advantage of dual-fuel propulsion lies in its flexibility to switch fuels depending on availability and cost while maintaining power output and operational reliability.

Efficiency Comparison: Diesel-Electric vs Dual-Fuel

Diesel-electric propulsion systems generally offer high efficiency in variable speed operations due to their ability to optimize engine loads and electric motor control. Dual-fuel propulsion enhances fuel flexibility and reduces emissions by switching between diesel and gas, but its efficiency can vary depending on fuel quality and engine management. Studies show diesel-electric systems achieve up to 10% better fuel efficiency in typical maritime conditions, while dual-fuel systems excel in compliance with environmental regulations through cleaner fuel utilization.

Environmental Impact and Emissions

Diesel-electric propulsion systems generate higher NOx and SOx emissions due to the combustion of heavy fuel oil, leading to significant environmental pollution. Dual-fuel propulsion utilizes a combination of liquefied natural gas (LNG) and diesel, significantly reducing greenhouse gas emissions by lowering CO2 output by up to 20-30% and nearly eliminating sulfur oxides. Methane slip remains a challenge in dual-fuel systems, but advanced engine technologies continue to improve emission control and enhance environmental sustainability.

Operational Flexibility and Versatility

Diesel-electric propulsion systems offer high operational flexibility by allowing variable power management and seamless switching between diesel engines and electric motors, optimizing fuel use across diverse maritime conditions. Dual-fuel propulsion systems provide versatility by enabling the use of both conventional marine diesel and cleaner liquefied natural gas (LNG), supporting compliance with stringent emission regulations and adapting to fluctuating fuel prices. Diesel-electric configurations are often preferred for complex operations requiring precise maneuvering, while dual-fuel systems excel in reducing carbon footprint without sacrificing performance.

Maintenance and Lifecycle Costs

Diesel-electric propulsion systems generally incur higher initial maintenance costs due to the complexity of electrical components but benefit from longer intervals between major overhauls, reducing overall lifecycle expenses. Dual-fuel propulsion, while offering fuel flexibility and potential fuel cost savings, demands specialized maintenance for gas handling and combustion systems, which can elevate upkeep costs and technical labor requirements. Lifecycle cost analysis often favors diesel-electric systems in vessels with predictable operating profiles, whereas dual-fuel systems prove cost-effective in routes with variable fuel availability and stricter emission regulations.

Fuel Availability and Infrastructure

Diesel-electric propulsion benefits from widespread diesel fuel availability and an extensive global refueling infrastructure, making it suitable for remote and high-traffic shipping routes. Dual-fuel propulsion systems rely on both traditional fuels and alternative options like LNG, which requires specialized infrastructure that is currently limited but rapidly expanding in key maritime hubs. The disparity in fuel availability and refueling infrastructure directly influences operational flexibility and route planning for vessels using these propulsion technologies.

Suitability for Various Vessel Types

Diesel-electric propulsion systems excel in vessels requiring precise maneuverability and energy efficiency, such as cruise ships, offshore support vessels, and hybrid ferries, due to their flexible power distribution and compact engine arrangement. Dual-fuel propulsion suits large cargo ships, tankers, and LNG carriers by offering fuel adaptability and reduced emissions, allowing operation on both liquid natural gas and conventional marine diesel. Vessel operational profiles, fuel availability, and environmental regulations heavily influence the selection between diesel-electric and dual-fuel systems for optimal performance and sustainability.

Future Trends in Marine Propulsion Technologies

Diesel-electric propulsion systems are gaining traction for their efficiency and reduced emissions, integrating advanced battery storage and smart energy management to optimize fuel consumption. Dual-fuel propulsion, capable of burning both traditional marine diesel and cleaner alternatives like LNG, is evolving with enhanced engine designs to meet stricter IMO emissions regulations while offering operational flexibility. Future trends emphasize hybridization, increased use of alternative fuels such as hydrogen and ammonia, and digital system integration to boost sustainability and performance in marine propulsion technologies.

Power management system

Diesel-electric propulsion utilizes an integrated power management system to optimize engine load and battery usage for fuel efficiency and emissions reduction, while dual-fuel propulsion relies on a power management system that dynamically switches between fuel types to maximize combustion efficiency and minimize operational costs.

Prime mover efficiency

Diesel-electric propulsion achieves higher prime mover efficiency through optimized diesel engine load management, while dual-fuel propulsion offers improved fuel flexibility but often experiences lower prime mover efficiency due to complex fuel mixing and ignition challenges.

Fuel flexibility

Diesel-electric propulsion offers moderate fuel flexibility by using diesel fuel or biofuels, while dual-fuel propulsion maximizes fuel adaptability by enabling seamless switching between diesel and natural gas, significantly reducing emissions and operational costs.

Emissions compliance

Diesel-electric propulsion systems typically produce higher NOx and particulate emissions compared to dual-fuel propulsion, which can switch between LNG and diesel fuel to achieve stricter emissions compliance with international regulations like IMO Tier III.

LNG bunkering

Diesel-electric propulsion systems typically require separate LNG bunkering infrastructure compared to dual-fuel propulsion systems, which optimize LNG bunkering efficiency by directly utilizing LNG as a primary fuel source.

Generator load sharing

Diesel-electric propulsion offers flexible generator load sharing by independently controlling multiple generators for optimal efficiency, whereas dual-fuel propulsion integrates fuel flexibility but requires complex load management systems to balance generator output between diesel and alternative fuels.

Redundancy architecture

Diesel-electric propulsion offers enhanced redundancy architecture through independent power generation units and flexible energy distribution, whereas dual-fuel propulsion relies on combined fuel systems that may introduce complexity but provide fuel versatility and backup options.

Hybridization potential

Diesel-electric propulsion offers higher hybridization potential with seamless integration of batteries for energy storage, while dual-fuel propulsion provides flexibility in fuel use but presents more complex hybridization challenges due to combustion variability.

Genset integration

Diesel-electric propulsion systems integrate gensets for efficient power management and reduced emissions, while dual-fuel propulsion leverages flexible genset integration to optimize fuel usage and comply with stricter environmental regulations.

IMO Tier III regulations

Diesel-electric propulsion systems offer superior compliance with IMO Tier III regulations through precise NOx emission control and efficient energy management compared to dual-fuel propulsion systems, which face challenges in consistently meeting stringent emission limits under variable fuel conditions.

Diesel-electric propulsion vs Dual-fuel propulsion Infographic

njnir.com

njnir.com