Marine air conditioning systems are specifically designed to handle the unique challenges of the maritime environment, such as salt corrosion, humidity control, and limited space on vessels. Unlike standard HVAC systems, marine air conditioning units incorporate robust materials and specialized filtration to ensure durability and efficiency at sea. These systems optimize air quality and temperature regulation onboard, improving comfort and operational reliability in marine vessels.

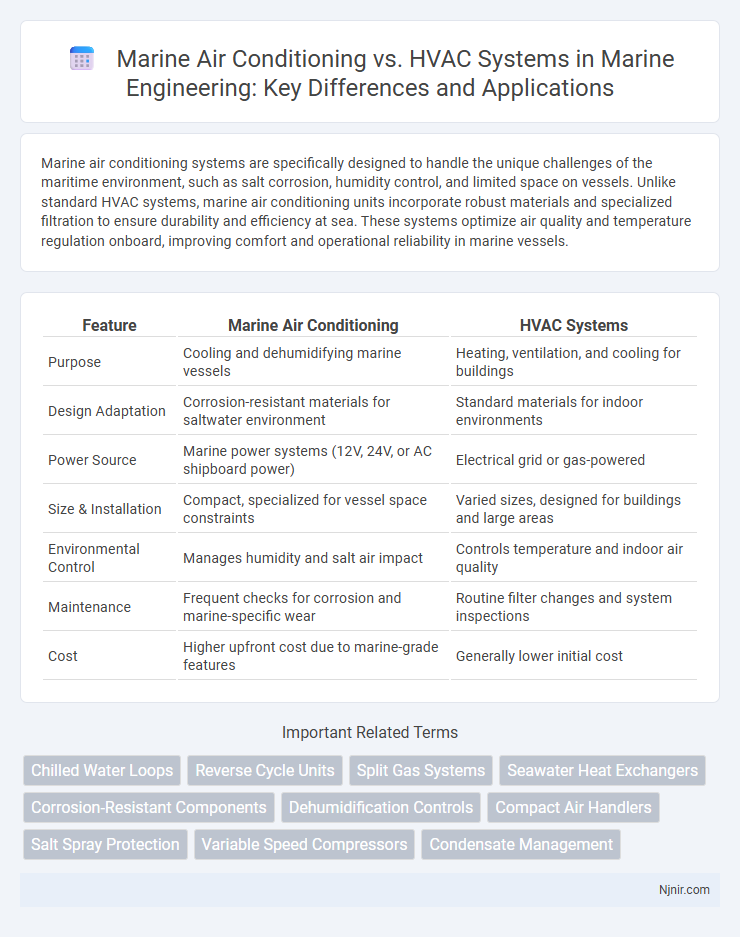

Table of Comparison

| Feature | Marine Air Conditioning | HVAC Systems |

|---|---|---|

| Purpose | Cooling and dehumidifying marine vessels | Heating, ventilation, and cooling for buildings |

| Design Adaptation | Corrosion-resistant materials for saltwater environment | Standard materials for indoor environments |

| Power Source | Marine power systems (12V, 24V, or AC shipboard power) | Electrical grid or gas-powered |

| Size & Installation | Compact, specialized for vessel space constraints | Varied sizes, designed for buildings and large areas |

| Environmental Control | Manages humidity and salt air impact | Controls temperature and indoor air quality |

| Maintenance | Frequent checks for corrosion and marine-specific wear | Routine filter changes and system inspections |

| Cost | Higher upfront cost due to marine-grade features | Generally lower initial cost |

Introduction to Marine Air Conditioning and HVAC Systems

Marine air conditioning systems are specifically designed to regulate temperature and humidity aboard vessels, providing comfort in harsh maritime environments with limited space and power resources. HVAC systems, while similar in function, are tailored for larger-scale applications and often incorporate advanced filtration and ventilation features suited to buildings rather than confined marine settings. Understanding the distinct engineering challenges, energy efficiency requirements, and environmental factors is essential when comparing marine air conditioning units to conventional HVAC systems.

Key Differences Between Marine and Traditional HVAC Systems

Marine air conditioning systems are specifically engineered to withstand corrosive saltwater environments, featuring corrosion-resistant materials and compact designs suited for limited onboard space, unlike traditional HVAC systems used in buildings. Marine systems prioritize energy efficiency and noise reduction to maintain comfort without disturbing marine vessel operations, while traditional HVAC units focus on larger-scale air handling and climate control for fixed structures. Controls and ventilation in marine units emphasize moisture management and seawater heat exchange, contrasting with the air filtration and thermal regulation priorities of standard HVAC systems.

Environmental Challenges in Marine Climate Control

Marine air conditioning systems are specifically designed to combat the harsh saline environment and high humidity levels found at sea, using corrosion-resistant materials and advanced moisture control technologies. HVAC systems in marine settings face unique environmental challenges including salt spray, constant temperature fluctuations, and limited ventilation space, which require robust filtration and specialized coatings to maintain efficiency and durability. Effective marine climate control solutions must prioritize energy efficiency and sustainable refrigerants to reduce environmental impact while ensuring reliable performance on vessels.

Energy Efficiency: Marine Air Conditioning vs HVAC Systems

Marine air conditioning systems are specifically designed to optimize energy efficiency by utilizing seawater for heat exchange, significantly reducing power consumption compared to traditional HVAC systems. HVAC systems, commonly used in land-based environments, often rely on less efficient refrigerant cycles and duct losses, resulting in higher energy usage. The adaptation of corrosion-resistant components in marine air conditioning further enhances operational efficiency and durability in harsh maritime conditions.

System Design and Space Constraints Aboard Vessels

Marine air conditioning systems are specifically engineered to accommodate the limited space and unique environmental conditions aboard vessels, featuring compact, corrosion-resistant components that ensure efficient cooling in tight quarters. Unlike standard HVAC systems, marine units prioritize lightweight materials and modular designs to optimize installation in confined engine rooms and cabins while maintaining robust performance under constant motion and saltwater exposure. The integration of seawater heat exchangers and vibration-dampening mounts in marine air conditioning systems addresses the challenges of shipboard space constraints and harsh marine atmospheres, providing reliable temperature control tailored to maritime operations.

Maintenance Requirements for Marine and Land-Based Systems

Marine air conditioning systems require specialized maintenance due to exposure to saltwater, humidity, and corrosive marine environments, necessitating frequent inspections of corrosion-prone components like evaporators and compressors. Land-based HVAC systems typically have easier access to parts and benefit from less aggressive environmental conditions, resulting in lower maintenance frequency and simpler servicing tasks. Both systems rely on regular filter changes and refrigerant checks, but marine units demand more rigorous corrosion control and seawater system flushing to ensure optimal performance and longevity.

Corrosion Resistance and Material Selection

Marine air conditioning systems prioritize corrosion resistance by utilizing materials such as titanium, marine-grade aluminum, and stainless steel to withstand harsh saltwater environments and prevent rust and degradation. HVAC systems designed for marine applications often feature advanced coatings and sacrificial anodes to enhance durability and extend equipment lifespan. Proper material selection ensures optimal performance and reduced maintenance costs in corrosive marine atmospheres compared to standard HVAC systems.

Cost Comparisons: Installation and Operation

Marine air conditioning systems generally have higher installation costs due to specialized components and corrosion-resistant materials required for the marine environment. Operational expenses for marine AC units tend to be elevated because of increased maintenance demands and energy consumption compared to standard HVAC systems used in residential or commercial buildings. HVAC systems typically offer lower upfront installation costs and more energy-efficient operation, benefiting from simpler installation and widespread availability of parts.

Impact on Crew Comfort and Vessel Performance

Marine air conditioning systems are specifically designed to regulate temperature, humidity, and air quality in harsh maritime environments, significantly enhancing crew comfort by preventing heat stress and improving sleep quality. Unlike standard HVAC systems, marine air conditioning units optimize energy efficiency to reduce fuel consumption, positively impacting vessel performance and operational costs. Effective climate control aboard ships also minimizes corrosion and equipment wear, contributing to longer vessel lifespan and safer, more productive maritime operations.

Choosing the Right System for Marine Applications

Selecting the right system for marine applications requires understanding the unique challenges of saltwater corrosion, limited space, and high humidity. Marine air conditioning systems are specifically designed to resist corrosion and efficiently manage moisture, enhancing comfort onboard. In contrast, traditional HVAC systems may lack these marine-specific features, making marine air conditioning the preferred choice for durability and performance on vessels.

Chilled Water Loops

Marine air conditioning systems utilizing chilled water loops offer enhanced energy efficiency and precise temperature control compared to traditional HVAC systems in maritime environments.

Reverse Cycle Units

Reverse cycle marine air conditioning units provide efficient year-round temperature control on boats by combining cooling and heating functions in a single system, outperforming traditional HVAC systems in energy efficiency and space-saving design.

Split Gas Systems

Split gas marine air conditioning systems offer superior energy efficiency and precise temperature control compared to traditional HVAC systems, making them ideal for marine environments.

Seawater Heat Exchangers

Seawater heat exchangers in marine air conditioning systems provide efficient cooling by using ocean water to dissipate heat, offering superior corrosion resistance and energy savings compared to conventional HVAC systems.

Corrosion-Resistant Components

Marine air conditioning systems feature corrosion-resistant components specifically designed to withstand harsh saltwater environments, unlike standard HVAC systems that may require additional protective measures to prevent corrosion damage.

Dehumidification Controls

Marine air conditioning systems provide superior dehumidification controls compared to traditional HVAC systems by using corrosion-resistant materials and specialized moisture-removal techniques tailored for high-humidity maritime environments.

Compact Air Handlers

Compact air handlers in marine air conditioning systems provide efficient space-saving climate control solutions tailored for confined vessel environments, outperform traditional HVAC units in size and corrosion resistance.

Salt Spray Protection

Marine air conditioning systems feature advanced salt spray protection coatings and corrosion-resistant materials that outperform standard HVAC systems in coastal and maritime environments.

Variable Speed Compressors

Variable speed compressors in marine air conditioning systems enhance energy efficiency and precise temperature control compared to traditional HVAC systems, reducing fuel consumption and operational costs.

Condensate Management

Marine air conditioning systems prioritize efficient condensate management through specialized drainage and corrosion-resistant materials to prevent water damage and ensure optimal performance in humid, saltwater environments, unlike standard HVAC systems.

marine air conditioning vs HVAC systems Infographic

njnir.com

njnir.com